Commercial Kitchen Prep Tables That Make the Cut

Share

The Unsung Hero of Every Successful Commercial Kitchen

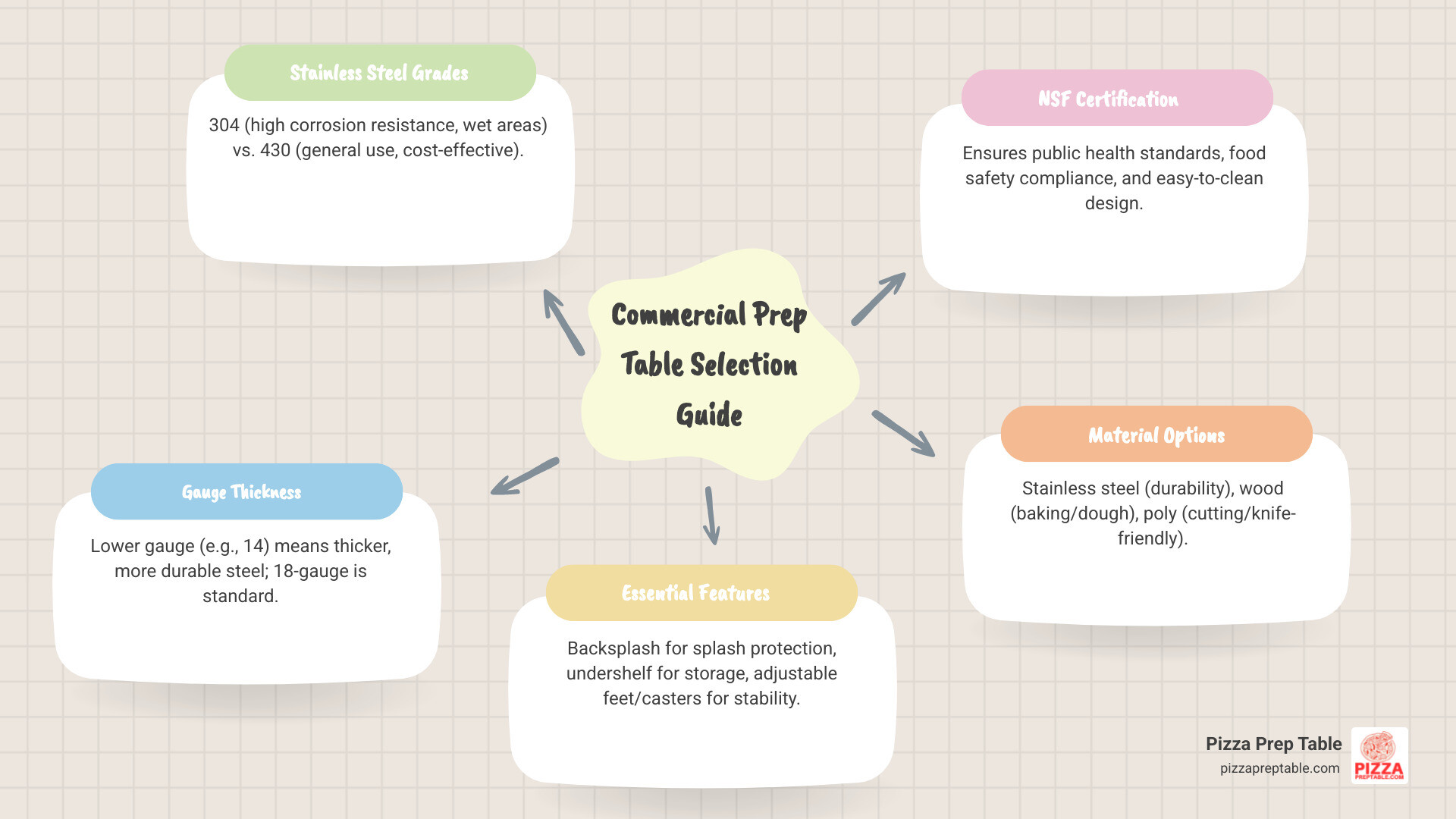

A commercial kitchen prep table is the backbone of any foodservice operation, serving as the central workspace where ingredients are prepared, dishes are assembled, and kitchen efficiency is determined. Here's what you need to know when shopping for one:

Key Features to Look For:

- Material: 304 stainless steel for durability and corrosion resistance

- Size: At least 2 feet deep by 3 feet wide for adequate workspace

- Construction: 14-18 gauge thickness for commercial durability

- Features: Backsplash, undershelf, and adjustable feet

- Certification: NSF-listed for food safety compliance

Commercial work tables are perhaps some of the most overlooked pieces of equipment in a busy restaurant kitchen, yet they're also one of the most important. These sturdy, NSF-listed surfaces are built for high-capacity kitchens and help optimize kitchen space, cut down cleaning time, and support food safety compliance.

Stainless steel dominates the market for good reason - it's many times more durable than tables made of wood or lighter materials and resists the corrosion that can damage prep tables in busy commercial environments.

Whether you're outfitting a new pizzeria or upgrading your existing kitchen, the right prep table will serve as the foundation for countless meals and years of reliable service.

I'm Sean Kearney, and my background in sales has taught me that having the right restaurant equipment can make all the difference in a food establishment's efficiency and profitability. Throughout my career helping cafes and restaurant chains select the perfect commercial kitchen prep table, I've seen how the right choice transforms kitchen workflow and sets businesses up for success.

Decoding Prep Table Materials: From Stainless Steel to Butcher Block

Picking the right material for your commercial kitchen prep table can feel overwhelming at first. But here's the thing - your choice will affect everything from how long your table lasts to how easy it is to keep clean. Let me walk you through the main options so you can make the best decision for your kitchen.

The Unbeatable Advantages of Stainless Steel

There's a reason why stainless steel dominates commercial kitchens everywhere. When you're running a busy restaurant, you need equipment that can handle whatever you throw at it - literally.

Durability is where stainless steel really shines. These tables take a beating day after day and keep coming back for more. The corrosion resistance means you won't find rust spots after a few months of heavy use like you might with other materials.

What really sold me on stainless steel when I started in this business was the non-porous surface. Unlike wood, there are no tiny cracks or pores where bacteria can hide and multiply. This makes your commercial kitchen prep table incredibly hygienic and helps you stay compliant with health department standards.

Cleaning is honestly a breeze. A quick wipe-down with sanitizer and you're good to go. No scrubbing, no worrying about stains - just clean and move on to the next task. In a busy kitchen, that time savings really adds up.

Let's talk grades for a moment. Type 304 stainless steel is the premium choice with higher nickel content, making it perfect for wet environments and heavy use. Type 430 is more budget-friendly and still plenty durable for most prep work, though it won't handle harsh chemicals quite as well.

Many tables combine stainless steel tops with galvanized steel components for the legs and shelves. This gives you that professional stainless work surface while keeping costs reasonable - a smart middle ground for many operations.

If you're curious about other premium options, check out our guide on stone prep tables for something truly unique.

When to Choose Wood or Poly Top Tables

Now, stainless steel isn't always the answer. Sometimes other materials are actually better for specific tasks.

Wood tops have a special place in certain kitchens. If you're doing a lot of baking, wood is fantastic for kneading dough and rolling out pastry. The surface gives you better grip and doesn't stick like stainless steel can. Plus, there's something appealing about the warm, natural look of wood - especially if customers can see your prep area.

But here's the catch with wood: it's porous. That means bacteria can hide in those tiny spaces, making it risky for raw meat prep. If you go with wood, dedicate it to specific tasks like bread making or vegetable prep.

Poly top tables are the secret weapon for kitchens that do lots of cutting and chopping. The surface is much gentler on your knives, so they stay sharp longer. That's money in your pocket right there.

These poly surfaces are also non-porous and NSF-listed, so you get the sanitation benefits without the knife-dulling effect of stainless steel. Some operations even use color-coding with different poly cutting boards to prevent cross-contamination - red for meat, green for vegetables, and so on.

For more details on cutting surfaces, our cutting board guide covers all the options.

The bottom line? Think about what you'll actually be doing on your prep table. A pizza shop might want all stainless steel for easy cleaning, while a bakery might benefit from a wood-top table for dough work. Many successful kitchens use a mix of materials, each optimized for different tasks.

Essential Features for the Perfect Commercial Kitchen Prep Table

When I'm helping pizzeria owners choose their perfect commercial kitchen prep table, I always tell them the same thing: it's not just about having a flat surface to work on. The features that come with your table can make the difference between a workspace that fights you every day and one that actually makes your job easier.

Think of these features as your kitchen's support team. They're working behind the scenes to keep you organized, stable, and efficient during those crazy dinner rushes.

Storage and Stability: Undershelves and Legs

Let's start with what's underneath your table, because that's where the real magic happens. A well-designed undershelf is like finding hidden storage space you never knew you had. Instead of cluttering your main work surface with containers, tools, and ingredients, you can tuck everything neatly below.

What makes a great undershelf? Adjustability is key. Many of our Gridmann tables feature adjustable galvanized steel undershelves that let you customize the height to fit your specific needs. Need to store tall containers? Lower the shelf. Want easy access to frequently used tools? Raise it up. The Regency work table takes this even further with an undershelf that can handle up to 380 pounds - that's serious storage capacity.

Here's a pro tip from my years in restaurant supply: make sure your undershelf sits at least 6 inches off the ground. It's not just good practice for cleanliness; it's often required for food safety compliance.

Now let's talk about what's holding everything up. Heavy-duty legs aren't just about looking sturdy - they're about actually being sturdy. Commercial tables typically feature legs made from galvanized steel or stainless steel, usually around 1 5/8" in diameter. These aren't the wobbly legs you'd find on a home table; they're built to handle the daily punishment of a busy kitchen.

But here's a feature that might seem small but makes a huge difference: adjustable bullet feet. If you've ever worked in an older building with uneven floors (and let's be honest, most of us have), you know how frustrating a wobbly table can be. These adjustable feet can provide up to an inch of adjustment, letting you level your table perfectly while protecting your floors from scratches.

| Feature | Heavy-Duty Tables | Medium-Duty Tables |

|---|---|---|

| Gauge | 14-16 gauge stainless steel | 18 gauge stainless steel |

| Construction | All stainless steel components | Stainless top with galvanized legs/shelf |

| Load Capacity | Up to 500 lbs on top, 380 lbs on shelf | Suitable for general prep work |

| Best For | High-volume kitchens, heavy equipment | Smaller establishments, budget-conscious buyers |

Mobility and Cleanliness: Casters and Backsplashes

Sometimes you need your commercial kitchen prep table to stay put, and sometimes you need it to move. That's where casters come in handy. These aren't just wheels - they're your ticket to kitchen flexibility.

Picture this: it's deep cleaning day, and you need to get behind your prep station. With casters, you can roll that table right out of the way. Hosting a special event and need to reconfigure your kitchen layout? No problem. The key is finding tables with at least two locking casters (the ones with brakes) so your table stays put when you need it to.

The Regency work table does this perfectly with galvanized steel legs and casters - two with brakes for stability, giving you the best of both worlds. For more insights on maximizing your workspace flexibility, check out Prep Tables That Work As Hard As You Do.

Now, let's talk about keeping your walls clean. A backsplash might not seem exciting, but it's your kitchen's unsung hero against splashes and spills. Whether it's a 4-inch or 6-inch high backsplash like you'll find on Regency work tables, or even a smaller 1-1/4" version like on Gridmann tables, this simple feature saves you countless hours of wall scrubbing.

Those rounded front and back edges on the tabletop aren't just for looks either. They make your workspace more comfortable and safer, reducing the risk of those painful bumps we've all experienced during busy shifts.

The Importance of NSF Certification

If you're new to commercial kitchen equipment, you'll hear "NSF certified" thrown around a lot. Don't let it intimidate you - it's actually one of the best things to look for.

NSF International is like the strict teacher who makes sure everyone follows the rules - except in this case, the rules are all about keeping your food safe and your customers healthy. When a commercial kitchen prep table is NSF-listed, it means it has passed rigorous testing for public health and safety standards.

What does this mean for you? First, food safety compliance becomes much easier. NSF-certified tables are designed with smooth, non-porous surfaces and minimal crevices where bacteria could hide. This makes cleaning and sanitizing straightforward, which is crucial for passing health inspections.

The durability testing that comes with NSF certification means your table is built to handle whatever your kitchen can throw at it. Gridmann tables, for example, earn their NSF certification by meeting strict standards for both quality and durability in commercial use.

Perhaps most importantly, NSF certification gives you peace of mind. You know you're investing in equipment that prioritizes the health and safety of your customers and staff. For a deeper understanding of what this certification really means, take a look at What NSF Certification means for food equipment.

When you're making this investment, these features aren't just nice-to-haves - they're the difference between a table that works with you and one that works against you.

Sizing, Integration, and Creating an Efficient Workflow

Your commercial kitchen prep table isn't just another piece of equipment - it's the conductor of your kitchen orchestra. When sized right and positioned thoughtfully, it transforms chaos into choreography, turning your kitchen into a well-oiled machine where every movement has purpose.

Choosing the Right Size for Your Commercial Kitchen Prep Table

Here's the truth: there's no one-size-fits-all answer when it comes to prep table dimensions. What works perfectly in a cozy neighborhood pizzeria might leave you drowning in a high-volume restaurant kitchen.

Start with the basics: most commercial kitchens need at least 24 inches deep by 48 inches wide for adequate workspace. But don't stop there - think about how your team actually works. Are they prepping massive batches of vegetables? Go longer with a 60-inch or 72-inch table. Working in a tight galley kitchen? A 30-inch depth gives you more elbow room without overwhelming the space.

Standard dimensions typically range from 48 inches to over 120 inches in length, with depths of 24 to 30 inches. But here's what the spec sheets don't tell you: measure your available space twice, then consider the flow of foot traffic around the table. Your staff needs room to move without bumping into each other during the dinner rush.

Task requirements matter just as much as available space. Heavy-duty prep work like tenderizing meat or kneading large batches of dough demands a sturdy, spacious surface. Lighter tasks like garnish prep or plating can work beautifully on smaller tables that serve double duty as equipment stands for mixers or small appliances.

For pizzeria owners specifically, your prep table size directly impacts your pizza production line efficiency. If you're running a pizza operation, check out our guide to Find the right size for your pizzeria for more targeted advice.

Integrating Your Commercial Kitchen Prep Table with Other Equipment

The magic happens when your commercial kitchen prep table works seamlessly with everything around it. Think of it as creating a conversation between your equipment - each piece should complement the others, not compete for attention.

Proximity to cooking appliances can make or break your kitchen's efficiency. Position your prep table near griddles, ranges, or fryers to create smooth "prep-to-cook" workflows. This isn't just about convenience - it's about reducing those precious seconds that add up to minutes during busy service. We've seen kitchens transform their speed by simply relocating prep tables closer to their cooking stations.

Integration with refrigeration keeps your cold chain intact while maximizing accessibility. Undercounter refrigerators tucked beneath work surfaces give you instant access to fresh ingredients. Even better, refrigerated prep tables combine cold storage with workspace, perfect for sandwich assembly or pizza topping stations. A Sandwich Prep Table Refrigerator exemplifies this brilliant integration, offering both convenience and food safety in one unit.

Placement near dishwashing stations completes the circle from prep to cleanup. Position tables within easy reach of three-compartment sinks or dish machines to facilitate quick tool cleaning and waste disposal. Pre-rinse faucets mounted nearby make cleanup a breeze, keeping your main prep areas spotless.

Creating dedicated work zones takes integration to the next level. Designate specific tables for raw meat prep, another for vegetables, and a third for final plating. This systematic approach doesn't just boost efficiency - it's your frontline defense against cross-contamination, keeping your customers safe and your health inspector happy.

The goal isn't just a functional kitchen - it's a space where every movement flows naturally from one task to the next, where your team can work at peak performance without fighting their environment.

Frequently Asked Questions about Commercial Prep Tables

After years of helping restaurant owners choose the perfect commercial kitchen prep table, I've heard just about every question you can imagine. Let me share the answers to the ones that come up most often – these insights can save you both time and money.

Can I place heavy equipment on my work table?

This is probably the question I get asked most, and the answer is a confident "yes" – but with some important caveats. The key is understanding what your table can actually handle.

Weight capacity is everything here. A heavy-duty table with 14-gauge or 16-gauge stainless steel can typically support much more weight than an 18-gauge table. Take the Eagle Group SMPT30108, for example – its 14-gauge, type 304 stainless steel top is built like a tank and can handle substantial loads without breaking a sweat.

The stability of your table matters just as much as its strength. Those sturdy 1 5/8" diameter legs aren't just for show – they prevent dangerous wobbling when you're using heavy equipment. The Regency 24" x 72" stainless steel work table is a perfect example, with a top shelf rated for up to 500 pounds.

Here's a pro tip from my years in the business: always distribute weight evenly across the surface. Even the strongest table can develop problems if you concentrate all the weight in one small spot. And please, always check the manufacturer specifications before placing any heavy equipment. Your 60-quart mixer might look innocent enough, but it could easily exceed what a lighter-duty table can safely support.

How do I properly clean and maintain a stainless steel prep table?

Keeping your commercial kitchen prep table clean isn't just about appearance – it's about food safety, longevity, and maintaining that professional look that customers notice.

Daily cleaning should be your bread and butter. After each shift, give the entire surface a thorough wipe-down with warm water and mild dish soap. This simple step removes food debris and grease before they can cause problems.

For sanitizing procedures in commercial kitchens, you'll need to go beyond basic cleaning. After washing, apply an approved food-safe sanitizing solution – whether that's a diluted bleach solution or quaternary ammonium sanitizer – following the product instructions to the letter. Let it air dry or wipe with a clean, dry cloth.

Here's where many people go wrong: they reach for abrasive cleaners or steel wool thinking they need extra scrubbing power. Don't do it! These harsh materials can scratch the surface and actually damage the protective layer that keeps your stainless steel corrosion-resistant. Stick with microfiber cloths, soft sponges, and gentle cleaners.

Over time, you might notice your table doesn't look quite as pristine as when it was new. That's where passivation comes in – a specialized treatment that restores the chromium oxide layer. While not something you'll do daily, it's worth knowing about for long-term maintenance.

For those unexpected moments when something goes wrong, we've got you covered with our guide on Fixing Your Pizza Prep Table Without Losing Your Toppings.

What is the difference between a 304 and 430 grade stainless steel top?

This question comes up in almost every conversation I have with restaurant owners, and understanding the difference can save you from making a costly mistake.

304 grade stainless steel is what I call the "gold standard" for commercial kitchens. It contains both chromium and nickel (typically 18% chromium and 8% nickel), and that nickel content makes all the difference. This grade offers superior corrosion resistance against the acids, alkalis, and salts that are constantly present in busy kitchens. It's incredibly durable and handles wet environments like a champ.

The Eagle Group SMPT30108, with its 14-gauge, type 304 stainless steel top, is a perfect example of this premium grade in action. Yes, it costs more upfront, but for wet environments and high-volume operations, it's worth every penny.

430 grade stainless steel takes a different approach. This ferritic stainless steel contains chromium but no nickel, making it more economical while still offering decent performance. It provides good resistance to oxidation and general corrosion, but it's not as tough against acids and prolonged moisture exposure.

Gridmann stainless steel tables often feature 18-gauge #430 stainless steel tabletops, offering a cost-effective solution that works well for many commercial applications. For general use in drier prep areas where budget is a primary concern, 430 can be perfectly suitable.

The bottom line? If your commercial kitchen prep table will live in a constantly wet area or face harsh cleaning chemicals daily, invest in 304 grade. For general dry prep work where you're watching costs, 430 grade can serve you well without breaking the bank.

Find the Perfect Prep Table to Lift Your Kitchen

As we wrap up our journey through commercial kitchen prep tables, I hope you can see why these workhorses are so much more than just another piece of equipment. They're the silent partners in every successful meal, the steady foundation that keeps your kitchen running smoothly when the dinner rush hits.

Think about it – we've covered everything from the unbeatable durability of 304 stainless steel that laughs in the face of busy kitchen chaos, to the specialized charm of wooden baker's tables that make kneading dough feel like an art form. We've explored how NSF certification gives you that peace of mind knowing your investment meets the highest food safety standards, and how features like adjustable undershelves and locking casters can transform your kitchen's flexibility.

Investing in quality isn't just about buying equipment – it's about investing in your team's efficiency and your customers' safety. When you choose the right commercial kitchen prep table, you're setting up your kitchen for success. You're cutting down on cleaning time, optimizing precious kitchen space, and creating a workspace where your staff can truly shine.

I've seen how the right prep table transforms kitchen workflow. It's the difference between a frazzled cook scrambling for space and a confident chef who has everything within arm's reach. These tables are built to handle whatever your busy kitchen throws at them, providing that reliable foundation for countless meals and years of dependable service.

At PizzaPrepTable.com, we get it. Whether you're running a cozy neighborhood pizzeria or managing a high-volume restaurant chain, we know that every kitchen has unique needs. That's why we've built our reputation on offering a wide selection of commercial prep tables that cover every budget and requirement. But more than that, we're here to share our expertise and help you find the perfect match for your operation.

We serve kitchens across the entire country – from the busy restaurant scenes in New York City, Los Angeles, and Chicago to the growing foodservice markets in Houston, Phoenix, Philadelphia, and Atlanta. Wherever you are, we understand the challenges you face and we're committed to providing solutions that work.

What really sets us apart is our financing options. We believe that both small independent shops and larger establishments deserve access to quality equipment without breaking the bank. Your dream kitchen shouldn't have to wait for the perfect financial moment.

Ready to give your kitchen the upgrade it deserves? Explore our complete collection of commercial prep tables to find the perfect fit for your kitchen. Let's help you create a workspace that works as hard as you do!