Cutting Edge Choices – Best Pizza Prep Table Cutting Boards

Share

Choosing Your Essential Pizza Prep Table Cutting Board

Choosing the right pizza prep table cutting board is key for any pizzeria owner or manager. It impacts everything from food safety to how smoothly your kitchen runs. Here’s a quick guide to help you make an informed choice:

- Size Matters: Pizza prep boards are typically deep, usually 19 to 24 inches wide. This gives you plenty of space for large pizzas. Boards for sandwich or mega-top tables are much shallower, around 10 inches deep.

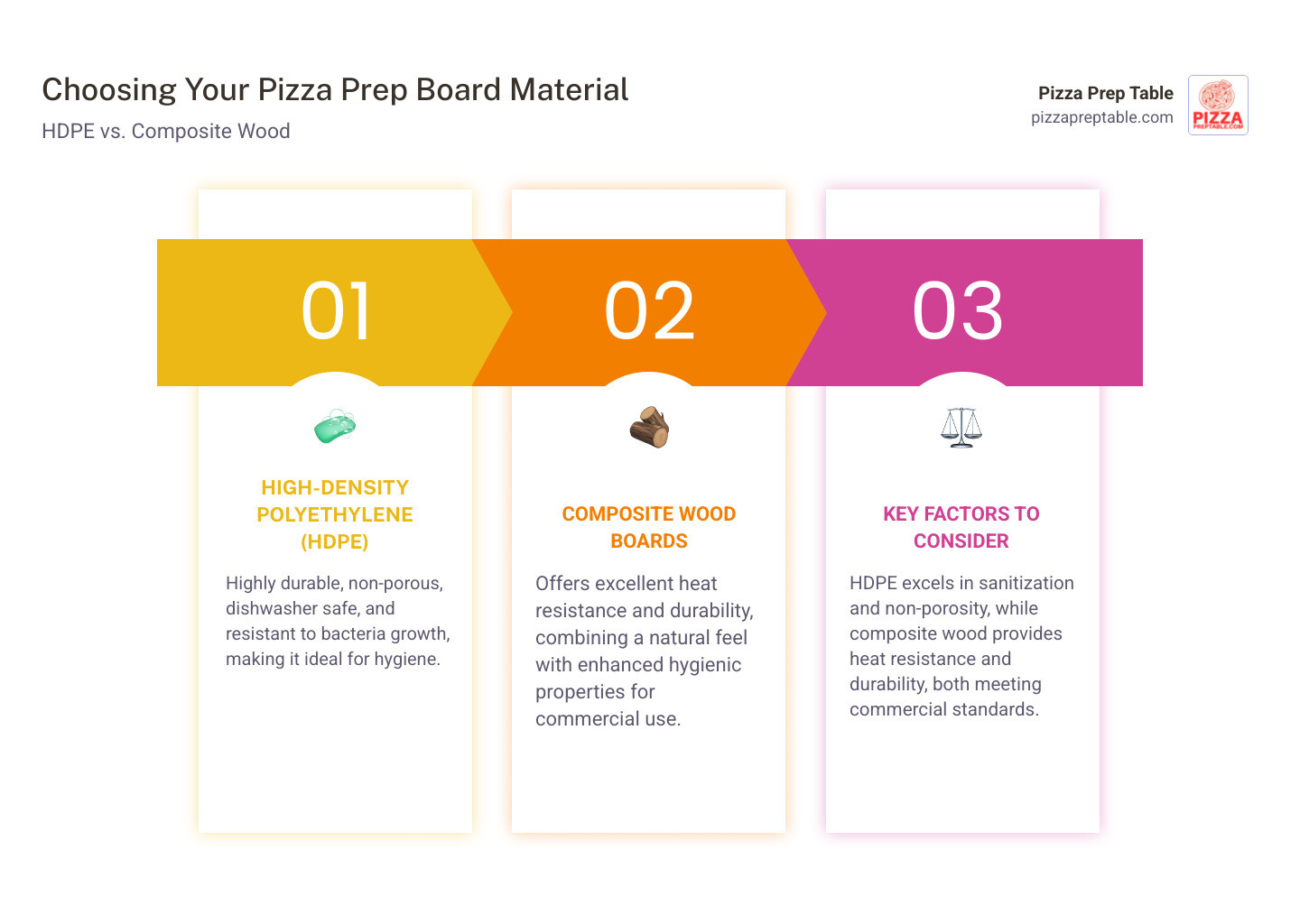

- Common Materials: Most commercial boards are made from high-density polyethylene (HDPE) plastic or composite wood. HDPE is durable and easy to clean.

- Certifications: Always look for NSF and USDA approvals. These certifications mean the board meets strict public health and safety standards.

- Replacement Time: Replace your board if it's stained, deeply scratched, or broken. This keeps your kitchen hygienic and protects your knives.

In a busy commercial kitchen, the pizza prep table cutting board is more than just a surface; it's the heart of your pizza-making operation. It's where fresh ingredients meet the dough, where efficiency is gained, and where food safety is paramount. Selecting the right board ensures smooth workflow and helps you meet strict hygiene standards. As detailed in "The Secret Sauce Behind Efficient Pizza Prep Stations", proper equipment is critical for success.

The Anatomy of a Pizza Prep Board: Materials and Dimensions

When you think about a pizza prep table cutting board, it's so much more than just a surface. It's a key player in your kitchen, built to handle the hustle and bustle of a busy commercial environment. This essential piece of equipment needs to be super tough, easy to keep sparkling clean, and perfectly sized for crafting those delicious pizzas your customers love.

The secret to a great board lies in its materials. We often see boards made from sturdy High-Density Polyethylene (HDPE) plastic, clever composite wood, or even woodfiber laminate. These aren't just random choices; they're picked because they can stand up to constant daily use, sharp knives, and all the rigorous cleaning that happens in a professional kitchen.

And let's talk size! A pizza prep table cutting board is designed to give you plenty of room to work. You'll typically find them with a generous depth of 19 to 24 inches. This extra space is a game-changer for rolling out dough, adding toppings, and easily maneuvering your pizza peel. It's a lot deeper than boards you'd find on other types of prep tables, which we'll explore soon! While depths can vary, common thicknesses are usually 1/2 inch, 3/4 inch, or 5/8 inch. This ensures a really sturdy surface that won't bend or flex under pressure. Plus, some boards are even reversible, giving you double the lifespan and flexibility!

If you're curious about other types of surfaces for your prep area, our guide on Stone Cold Deliciousness: Granite and Marble Pizza Prep Tables Reviewed offers some interesting insights.

Common Materials and Their Benefits

Now, let's get into the nitty-gritty of what these materials bring to your pizzeria. Each one has its own special superpowers for a busy kitchen.

| Feature | High-Density Polyethylene (HDPE) | Composite Wood |

|---|---|---|

| Durability | Excellent; resistant to chipping, cracking, and warping. | Very good; strong, dense, less prone to warping than solid wood. |

| Knife-Friendliness | Good; won't dull knives quickly, but can develop grooves over time. | Excellent; gentle on knife edges, feels like cutting on wood. |

| Hygiene | Superior; non-porous, resistant to bacteria absorption, easy to sanitize. | Very good; non-porous, often infused with resins making them less absorbent than traditional wood. |

| Maintenance | Easy; typically dishwasher safe, simple to clean with soap and water. | Easy; often dishwasher safe, requires minimal maintenance, may benefit from occasional oiling (if specified). |

Polyethylene (HDPE): This material is a true workhorse in commercial kitchens, and for good reason! HDPE boards are incredibly tough, shrugging off chips, cracks, and warping even with constant daily use. What makes them a hygiene superstar is their non-porous surface. This means they won't soak up liquids, odors, or pesky bacteria, making them super easy to sanitize. We especially love that most polyethylene boards are dishwasher safe. This allows for a thorough, worry-free cleaning in commercial dishwashers – a huge time-saver and a critical step for food safety. You'll often see common sizes like a 12" x 72" x 1/2" prep table cutting board, showing just how versatile this material is.

Composite Wood: These boards offer a fantastic alternative, giving you the familiar feel and knife-friendliness of traditional wood, but without its common drawbacks. They're made from wood fibers pressed together with strong resins, making them incredibly durable and resistant to heat. Our research shows that these composite boards are often "more impervious to knife cuts and bacteria than standard HDPE or nylon cutting boards." That's a big win for both longevity and keeping things safe! Think of Read Products Woodfiber Laminate Pizza Boards, first developed way back in the 1960s. They're known for being durable, lightweight, hygienic, and heat-resistant – they won't even conduct heat! It's like they "work like wood but clean like plastic," and yes, they're dishwasher safe. This makes them incredibly versatile for all your prep, cutting, and even serving needs. You can find them in various sizes, including a handy 20" x 20" equal slice board that's just 1/4" thick.

Choosing between HDPE and composite wood often comes down to what feels right for your team and your kitchen's specific needs. But rest assured, both are excellent choices for your pizza prep table cutting board.

Standard vs. Custom Dimensions

While many pizza prep table cutting boards come in standard sizes, perfectly designed for specific equipment models, commercial kitchens often need a little more wiggle room. This is where options like OEM (Original Equipment Manufacturer) replacement boards and custom-cut solutions really shine.

Many brands, like Avantco, offer direct OEM replacement boards. For example, their SSPPT-2 pizza prep tables use a specific 3/4" thick, 19 1/2" deep cutting board that's 67" wide, ensuring a perfect, snug fit. You'll also find common replacement sizes like a 12" x 72" x 1/2" prep table cutting board, which weighs in at about 7 pounds.

But what if your board doesn't have pre-drilled holes for those little pegs or mounts? No worries! That's where custom-cut options and the magic of "field drilling" come in. This simply means the holes for the pegs can be drilled right there on-site, ensuring a flawless fit with your existing prep table. This flexibility is a lifesaver, especially if you have older models or a unique kitchen layout. Some suppliers, like Cutting Board Company, even provide simple instructions on how to drill these peg holes yourself, offering "OEM quality at a fraction of the price!" This approach can save you both time and money, making sure you get a precise fit without waiting on a specialized factory order.

Whether you're swapping out a well-loved board or setting up a brand-new station, understanding your options for standard and custom dimensions ensures your pizza prep table cutting board fits perfectly into your daily workflow. For more tips on finding these essential components, be sure to check out our guide on Don't Lose Your Cool: Where to Find Pizza Prep Table Parts.

Not All Prep Boards Are Equal: Pizza vs. Sandwich Tables

Alright, let's clear up a common misconception: it's tempting to think a cutting board is just a cutting board, right? But in the busy world of commercial kitchens, especially when it comes to prep tables, nothing could be further from the truth! The design of a pizza prep table cutting board is actually quite different from those you'd find on sandwich or mega-top prep tables. And trust us, there's a very good reason for it!

The biggest, most noticeable difference boils down to one thing: workspace depth. Think about it – pizza prep tables are built specifically for the unique demands of assembling those glorious, cheesy pies. They typically boast a deep prep area, usually ranging from 14 to 19 inches, including the board itself. And that pizza prep table cutting board? It's often a generous 19 to 24 inches wide! This expansive, deep surface gives your team plenty of room to lay out large pizza doughs, spread sauce evenly, pile on copious amounts of cheese and toppings, and effortlessly maneuver pizza peels. It means you can layer toppings directly onto the pizza while it's on the peel, speeding up your prep time and getting those delicious pizzas to hungry customers much faster. As many seasoned pros will tell you, the typically raised, angled refrigerated rail and deep prep area make these tables absolutely "ideal for assembling pizzas."

Now, let's compare that to sandwich and mega-top prep stations. These tables usually feature a much shallower prep or cutting board area. We're talking around 8 or 9 inches deep, sometimes stretching to about 10 inches. This shallower depth is absolutely perfect for what they're designed for: building sandwiches or salads. Here, ingredients are often scooped or placed directly onto bread or greens, a task that doesn't require the expansive real estate of a pizza board. For example, even within the same manufacturer, you'll see differences. Randell's Raised Rail 'Pizza' Prep Tables (their PCB models) come standard with a 16-inch wide poly cutting board, which is great for pizza. But their Mega Top Raised Rail 'Pizza' Prep Tables, while still called "pizza" tables, feature a 10-inch wide poly cutting board. This highlights that "mega top" often refers to more pan capacity, but a shallower cutting surface more akin to what you'd use for sandwiches.

This difference in depth isn't just about size; it's all about workflow design. A deeper pizza prep table cutting board allows for much more ergonomic movement when handling large pizzas and peels. It prevents your staff from having to lean too far over or constantly adjust their position, which can save a lot of strain over a busy shift. While you could technically use a pizza prep table for sandwich or salad prep (it just might feel a bit overkill!), the reverse is definitely not true. A standard sandwich prep table simply doesn't offer the necessary space and depth for efficient, high-volume pizza assembly.

Understanding this crucial distinction is key to making sure you invest in the right equipment for your specific culinary needs. It's about optimizing your kitchen's flow and ensuring your team can work efficiently and comfortably. For a broader look at different commercial prep stations and their unique roles, be sure to consult our detailed guide on Table Talk: Restaurant Kitchen Prep Tables Explained.

Choosing the Right Pizza Prep Table Cutting Board: Features and Certifications

When you're outfitting your commercial kitchen, picking the right pizza prep table cutting board is a big deal. It's not just about finding a surface; it's about ensuring everything runs smoothly, stays super clean, and meets all those important food safety standards. This board is truly at the heart of your pizza-making magic! For a broader perspective on selecting kitchen equipment, our guide on Table Manners: Picking the Perfect Kitchen Prepping Table offers useful insights.

Key Features of a Commercial Pizza Prep Table Cutting Board

A top-notch pizza prep table cutting board offers so much more than just a flat spot to work. It brings key features that truly boost efficiency, keep things safe, and stand up to the hustle and bustle of a busy kitchen.

First off, durability is a must-have. Your board will face constant knife cuts, scraping, and heavy use every single day. It needs to be tough enough to handle all that action without quickly getting deep grooves or splintering. That's why materials like HDPE and composite wood are such popular choices - they're built to last!

Next, consider reversibility. A board you can flip over and use on both sides essentially doubles its lifespan! It's a simple, smart feature that helps you get more value from your investment. Then there's ease of cleaning. In a commercial kitchen, quick and thorough cleaning isn't just nice, it's absolutely essential. Non-porous boards that are dishwasher safe (like many polyethylene and composite options) make sanitation a breeze and are champions at preventing nasty bacterial growth.

Finally, a non-slip surface is super important. While often integrated into the table design itself, a board that stays put during vigorous prep work is safer and more efficient. No one wants their board sliding around when they're trying to quickly slice pepperoni!

Beyond the standard rectangular boards, you can also find specialized options that really streamline specific pizza-making tasks:

- Round Cutting Boards: These are fantastic for portioning out individual pizzas or for serving. They're typically thin, around 1/4 inch thick, and come in various diameters (like 8 to 22 inches). They're often dishwasher safe and resistant to absorption, cuts, and stains, offering long-lasting durability for both cutting and serving.

- Equal-Slice Boards: These clever boards often feature pre-marked guides or grooves. They're designed to help you ensure every pizza slice is perfectly uniform. Imagine a 20" x 20" equal slice board, 1/4" thick, guiding you to consistent portions every time.

Investing in these smart features and specialized boards can make a huge difference in how precise and speedy your pizza preparation becomes. Exploring these specialized options can help you find the perfect fit for your kitchen's needs.

Why Certifications Matter

In the food service world, safety isn't just a word; it's everything. That's precisely why certifications like NSF and USDA approval are non-negotiable for any commercial pizza prep table cutting board. These aren't just fancy stickers; they're your guarantee that the equipment meets super strict standards designed to keep everyone safe and healthy.

NSF Certification from NSF International means your cutting board has been put through its paces and certified to meet tough public health and safety standards. For cutting boards, this means checking things like material safety, how easy it is to clean, and its resistance to bacterial growth. An NSF-certified board basically screams, "I'm easy to clean, non-toxic, and designed to stop food contamination!" For instance, True's NSF & USDA approved cutting boards are specifically designed to help you "prep your food confidently."

Then there's USDA Approval. This certification often focuses on the material's suitability for touching food, especially meats and poultry. It's a stamp of approval that says the material is safe, non-toxic, and won't absorb anything nasty. This is crucial in busy kitchens where preventing cross-contamination is a top priority.

Both certifications guarantee that the materials used are top-notch food-grade materials and that the board's design supports excellent hygiene standards. This is vital for preventing the spread of foodborne illnesses. When you see these certifications, you can feel totally confident that your pizza prep table cutting board meets the highest sanitation and safety benchmarks. It gives you a safe and reliable surface for all your delicious pizza prep needs! You can even View a sample sticker to see what these important certifications look like on commercial equipment.

Longevity and Hygiene: Maintenance and Replacement

Even the most durable pizza prep table cutting board won't last forever without proper care, and knowing when to replace it is crucial for maintaining hygiene and operational efficiency. These boards are subjected to constant knife action and contact with various ingredients, making them prime spots for bacterial buildup if not managed correctly.

Best practices for cleaning and maintaining your pizza prep table cutting board involve daily routines. After each use, or at minimum at the end of each shift, the board should be thoroughly cleaned. This typically involves scraping off any food debris, washing with hot water and a commercial-grade detergent, and then rinsing. Sanitizing procedures are equally important; this can be done using a chemical sanitizer solution or, ideally, by running the board through a commercial dishwasher, especially for poly and composite wood boards that are dishwasher safe. This rigorous cleaning prevents cross-contamination between different food types and ensures your board remains a safe surface for food preparation.

When to Replace Your Pizza Prep Table Cutting Board

Knowing when to bid farewell to an old pizza prep table cutting board is vital for the health of your kitchen and the quality of your product. Here are the tell-tale signs:

- Deep Grooves or Cuts: Over time, knife blades will create grooves in the board's surface. Once these grooves become deep enough to be difficult to clean, they can harbor bacteria and become a breeding ground for pathogens, making the board unsafe.

- Heavy Staining: While some staining is cosmetic, persistent, deep stains can indicate that the board material has broken down or become porous, making it harder to sanitize effectively.

- Warping: If your board starts to warp or bow, it creates an uneven surface that can be dangerous for cutting and compromise the stability of your prep area.

- Visible Damage: Any cracks, chips, or splintering are clear indicators that the board needs immediate replacement. These damaged areas can trap food particles and bacteria, or even contaminate food with small plastic pieces. As one source humorously put it, if your board is "not cutting it anymore (pun intended)," it's time for a change!

The benefits of timely replacement are significant:

- Protecting Cutlery: A heavily grooved or damaged cutting board can dull your knives much faster, leading to more frequent sharpening and decreased efficiency. A smooth, clean surface ensures your cutlery stays sharp.

- Improving Hygiene: Replacing worn boards directly contributes to a safer food environment by eliminating potential bacterial hiding spots. This is a critical step in preventing foodborne illnesses and maintaining health code compliance.

- Easier Cleanup: A new, smooth board is much easier and quicker to clean and sanitize, saving your staff valuable time during busy shifts and end-of-day routines.

- Saving Time and Money: While it might seem like an expense, replacing a worn board can save you time on cleaning, extend the life of your knives, and prevent costly health code violations.

Regular inspection of your pizza prep table cutting board should be a standard practice. If you notice any of these signs, don't hesitate to replace it. Your kitchen's efficiency and food safety depend on it. For more insights into maintaining your commercial pizza prep equipment, explore our Commercial Pizza Prep Table guide.

Frequently Asked Questions about Pizza Prep Table Cutting Boards

Got a few more questions about your pizza prep table cutting board? We hear you! It’s smart to be thorough when it comes to such a vital part of your kitchen. Here are some of the most common questions we get, with clear answers to help you make the best choices.

What is the most hygienic material for a commercial pizza prep table cutting board?

When it comes to keeping things super clean in a busy commercial kitchen, High-Density Polyethylene (HDPE) is often the top choice for a pizza prep table cutting board. Think of it as your hygiene superstar! HDPE is non-porous, which means it doesn't soak up liquids, odors, or — most importantly — bacteria. Plus, it can handle the intense heat and sanitizing cycles of a commercial dishwasher.

To be extra sure, always look for boards that are NSF-certified. This special stamp means the board has met strict public health standards for design, materials, and cleanliness. It gives you peace of mind that you're using a surface that’s designed to keep your food safe and your kitchen spotless.

How do I know what size replacement board to buy?

Replacing your pizza prep table cutting board should be a perfect fit, like a glove! The easiest way to get the right size is to simply measure. Grab a tape measure and note down the length and depth of your current board. If you don't have the old board, measure the exact space it fits into on your prep table.

But here’s a pro tip: always double-check the manufacturer's specifications for your specific pizza prep table model. This is the best way to ensure you get a board that’s not just the right size, but also has the correct thickness and any necessary features for your particular unit. No one wants a wobbly board in the middle of a pizza rush!

Can I use a wood cutting board on my pizza prep table?

This is a great question, and it has a bit of a nuanced answer! While traditional solid wood cutting boards can be used in some settings, they aren't as common for commercial pizza prep table cutting boards in busy pizzerias. Why? Because traditional wood is porous, meaning it can absorb liquids and bacteria, making it harder to sanitize thoroughly and a potential concern for food safety inspectors. They also require more maintenance, like oiling, to stay in good shape.

However, you'll find that composite wood or woodfiber laminate boards are much more popular in commercial kitchens. These clever boards give you the familiar feel and knife-friendliness of wood, but with the hygienic benefits of plastic. Many of these are NSF-certified and even dishwasher safe, making cleanup a breeze. So, you get the best of both worlds: a surface that’s gentle on your knives and easy to keep sparkling clean, without the worries of traditional wood.

Conclusion: Making the Right Choice for Your Pizzeria

Whew! We've covered a lot of ground, haven't we? From durable materials to crucial certifications, it's clear that your pizza prep table cutting board is so much more than just a surface. It's truly a silent hero in your kitchen, impacting everything from how quickly your team can assemble pizzas to the safety and quality of every delicious slice.

Making the right choice for your pizzeria boils down to a few key considerations we've explored. Think about the material – whether it's the tough, hygienic High-Density Polyethylene (HDPE) or the knife-friendly composite wood. Consider the perfect size to match your specific pizza prep table, remembering that deeper boards are crucial for efficient pizza assembly. And, of course, always prioritize those vital certifications like NSF and USDA approval, which are your assurance of food safety and quality. Lastly, don't forget the importance of proper maintenance to keep your board in top shape and know when it's time for a fresh start.

Investing a little thought into the right pizza prep table cutting board pays off big time. A well-chosen board doesn't just look good; it actively helps improve efficiency in your kitchen, ensures peak food safety for your customers, and contributes to that consistent, mouth-watering food quality that keeps them coming back for more. It really is a small but mighty piece of equipment that streamlines your workflow and protects your valuable knives, making sure your operation runs smoothly every single day.

Here at PizzaPrepTable.com, we get it. We understand the unique hustle and bustle of the pizza world. That's why we're proud to offer a wide range of commercial pizza prep tables and all the essential accessories – including, of course, the perfect cutting boards – to help you equip your kitchen for absolute success. We're here to help you make those smart, cutting-edge choices that will really lift your business, one delicious pizza at a time!