Cut Above the Rest: Finding Your Perfect Commercial Dough Cutter

Share

Why Every Commercial Kitchen Needs the Right Dough Cutter

A commercial dough cutter is essential equipment for dividing large dough batches into uniform portions with speed and consistency. These machines range from simple manual tools to fully automated systems that can process hundreds of portions per hour.

Key Types of Commercial Dough Cutters:

- Manual Cutters - Bench scrapers, dough wheels, and specialty cutters ($5-$50)

- Semi-Automatic Dividers - Hand-press or lever-action machines that divide 20-40 portions ($500-$3,000)

- Automatic Dividers - High-volume electric or hydraulic systems ($3,000-$10,000+)

- Divider-Rounders - Combination machines that cut and shape dough simultaneously

What to Consider:

- Capacity: Portions per hour and batch size

- Portion Range: Typical weight range is 30g to 140g (1-5 oz)

- Material: Food-grade stainless steel for durability

- Footprint: Counter-top vs. floor models

The global commercial dough divider market was valued at $1.2 billion in 2022 and is projected to grow at a CAGR of 5.2% through 2030, driven by the demand for labor-saving automation.

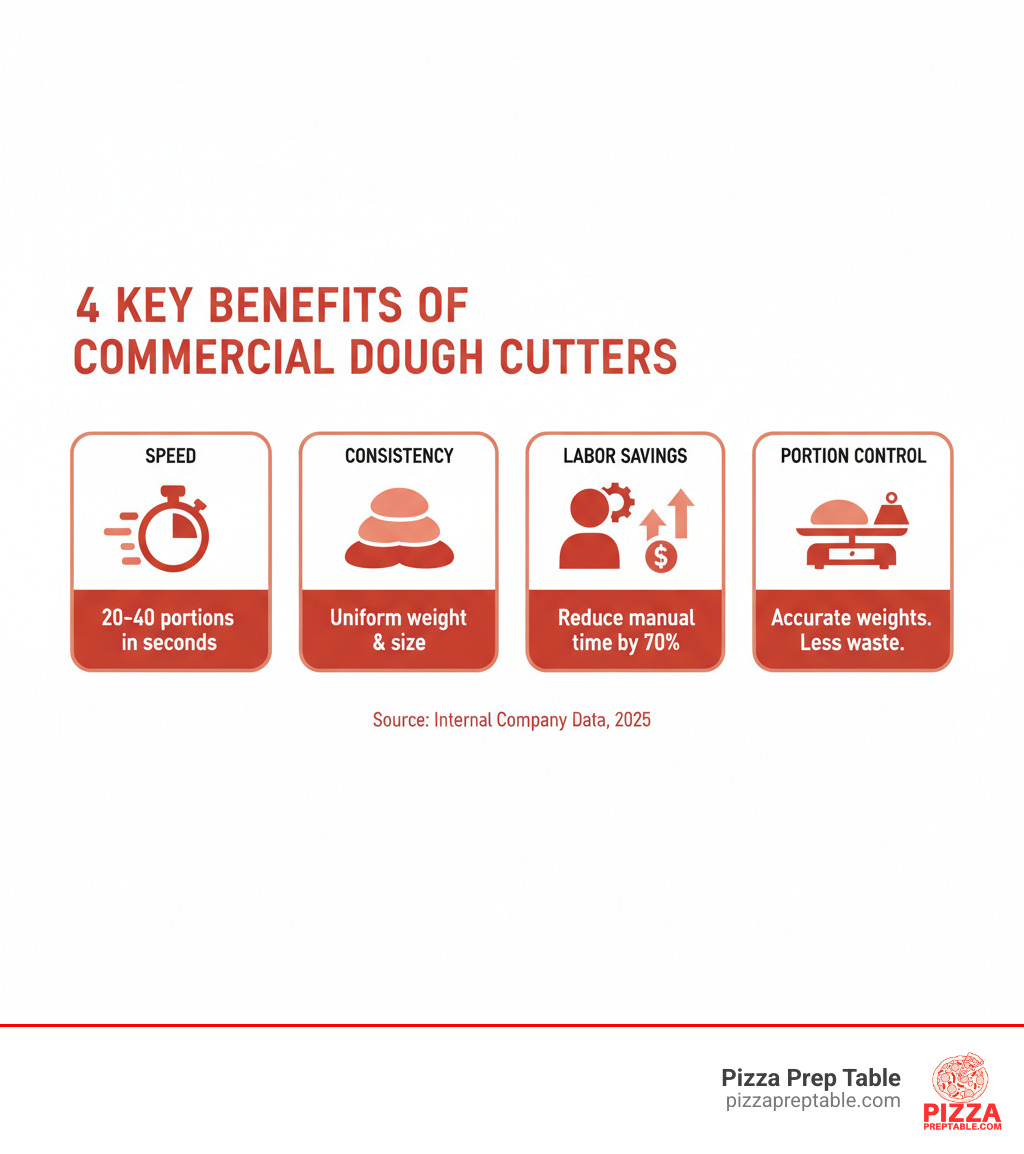

For any pizzeria or bakery, the right dough cutter transforms operations. It replaces slow, inconsistent hand-portioning with a system that produces uniform portions in seconds. This leads to faster service, consistent product quality, and reduced labor costs—critical advantages for any food business. While manual tools work for low-volume needs, a semi-automatic or automatic divider becomes essential as you grow, ensuring every pizza base or loaf weighs exactly what it should.

Choosing the right cutter involves balancing factors like material quality, automation, capacity, and brand reputation against your budget. Beyond the purchase price, consider shipping, installation, and maintenance. My experience in the restaurant equipment industry has shown that finding the right commercial dough cutter is about matching the equipment to your production needs and budget. This guide will walk you through the types of cutters, key features, and how to make a smart investment.

Why Your Kitchen Needs a Dough Divider

If you're still hand-portioning dough, you're working harder than necessary. A commercial dough cutter is not just another gadget; it's a tool that frees you from hours of repetitive prep, allowing you to focus on growing your business.

Imagine dividing a large batch of dough into 36 perfectly equal portions in under a minute. A dough divider makes this a reality, saving significant time and freeing up staff for other important tasks like customer service or prepping other ingredients.

Beyond speed, a divider delivers perfect consistency. Hand-portioning leads to variations that affect baking and customer experience. A divider eliminates guesswork, ensuring each portion is precisely measured for consistent product quality every time. Your pizzas will bake evenly, your bread will rise predictably, and your customers will get the same great product with every visit. This consistency builds trust and loyalty.

Accurate portion control also improves cost management. Over-portioning by hand adds up, increasing food costs. A divider ensures you use the exact amount of dough needed, reducing waste and keeping your recipe costing accurate. Your inventory becomes more predictable, and your profit margins are protected.

A good dough divider is also versatile, handling different dough types for pizza, rolls, bagels, or pastries. You can easily adjust portion weights to match your daily menu. It's an essential piece of commercial food prep equipment for any serious bakery or pizzeria.

The reduced labor costs alone can often justify the investment. By automating a tedious and repetitive task, you reduce physical strain on your staff and minimize burnout. Your team can then focus on more skilled work that requires a human touch.

In short, a commercial dough cutter helps you work smarter, deliver a better product, and build a more profitable business.

Slicing Through the Options: Types of Dough Cutters

Shopping for a commercial dough cutter can feel overwhelming due to the variety of options. However, understanding the different types of dough processing equipment is simple. The key is to match the machine to your production needs, budget, and kitchen space.

Let's break down the three main categories, from simple hand tools to sophisticated automated systems.

Manual Dough Cutters

Simple and affordable, manual cutters are great for small-scale operations.

- Bench scrapers: These rectangular blades are excellent for dividing small dough batches.

- Dough wheels: Heavy-duty rolling blades work well for cutting raw dough into strips.

- Rocker knives: Their long, curved blades can portion an entire sheet of dough with one motion.

- Specialty cutters: These are designed for specific products like donuts, croissants, and biscuits.

These tools are perfect when you're mastering pizza dough kneading in your stand mixer and only need to portion a few batches. However, they require significant time and effort for high volumes.

Semi-Automatic and Manual Dough Dividers

Bridging the gap between manual tools and full automation, semi-automatic dividers are ideal for small to medium-volume kitchens. Using a hand-press or lever, you can cut a large mass of dough into multiple equal portions in one motion. A typical model can divide dough into 36 pieces at once, with portion weights from 30 to 140 grams (roughly 1 to 5 ounces). This is a huge time-saver compared to dividing by hand on your commercial kitchen prep tables.

These machines offer remarkable consistency with minimal physical effort and are generally compact enough for a countertop. For a pizzeria making 50-100 pizzas a day, this level of automation often hits the sweet spot between performance and price.

Automatic Dough Dividers and Rounders

For industrial-level production, automatic dough dividers are essential. You load the hopper, set the portion weight, and the machine does the rest using powerful hydraulic or electric systems. The real game-changer is the divider-rounder combination machine, which not only cuts the dough but also shapes each portion into a uniform ball, ready for proofing. This eliminates an entire step in your production process.

The labor-saving benefits are substantial. For high-volume operations, the return on investment comes quickly through reduced labor costs and eliminated waste. The efficiency gains are a key reason for the projected 5.2% annual growth in the commercial dough divider market. Pairing an automatic divider with a quality spiral dough mixer creates a highly efficient production line capable of handling nearly any volume.

The Ultimate Buyer's Guide to Your Next Commercial Dough Cutter

Choosing the right commercial dough cutter can transform your kitchen's workflow. The best machine isn't the most expensive one; it's the one that fits your production volume, budget, and team. When evaluating options from commercial kitchen equipment suppliers, focus on what matters for your daily operations. A well-chosen cutter means consistent portions, faster production, and less waste.

Let's walk through exactly what you need to consider to make a smart choice.

Key Features to Consider for a Commercial Dough Cutter

Focus on these critical features to determine if a machine is right for you:

- Capacity: How many portions do you need per hour during peak times? Match the machine to your peak demand to avoid bottlenecks.

- Portion Weight Range: Ensure the machine can handle your smallest and largest required portions. A versatile commercial dough divider cutter adjustable from 5 to 200G offers great flexibility.

- Automation Level: Match the technology to your labor and budget. Manual tools are cheap, semi-automatic machines reduce strain, and fully automatic systems offer maximum speed.

- Footprint and Power: Carefully measure your available space and check the machine's power requirements (e.g., 110V, 220V) against your electrical setup.

- Ease of Use: Simple controls, whether a lever or a digital display, mean less training time and fewer errors.

Material, Build Quality, and Durability

The materials and construction quality determine a machine's longevity. Look for food-grade stainless steel, specifically SUS304, for all parts that touch dough. It's durable, hygienic, and resists corrosion. Cheaper materials can rust or chip, creating safety hazards.

A solid frame, precise moving parts, and quality blades indicate a well-built machine that can withstand daily use. NSF certification is your assurance that the equipment meets public health and safety standards. It's a key factor for health inspections and customer safety. A commercial dough cutter with superior materials and NSF certification may cost more upfront but will save you money in the long run through reliability and durability.

Understanding the Price Tag of a Commercial Dough Cutter

Prices for commercial dough cutters range from under $1,000 for manual dividers to over $10,000 for automatic systems. This reflects differences in automation, capacity, and materials.

- Entry-Level ($500 - $1,000): Manual or basic semi-automatic dividers, great for small operations.

- Mid-Range ($1,000 - $3,000): More robust semi-automatic models for growing businesses with steady daily use.

- High-End ($3,000 - $10,000+): Fully automatic dividers and divider-rounders for high-volume production. These are often considered industrial dough cutters.

Automation level, capacity, material quality, and brand reputation are the main drivers of price. The table below provides a quick comparison:

| Model Type | Key Features | Capacity | Materials | Typical Price Range |

|---|---|---|---|---|

| Entry-Level (Manual) | Basic hand-press, simple operation, minimal moving parts | Low-medium (20-40 portions/batch) | Stainless steel, some plastic components | $500 - $1,000 |

| Mid-Range (Semi-Auto) | Lever-action, consistent portioning, durable construction | Medium (300-600 portions/hour) | Food-grade stainless steel | $1,000 - $3,000 |

| High-End (Automatic) | Electric/hydraulic, programmable, integrated rounding, high throughput | High (1000+ portions/hour) | Heavy-duty stainless steel, advanced components | $3,000 - $10,000+ |

Beyond the Sticker Price: Hidden Costs and Smart Buying

The sticker price is just the start. Be prepared for additional costs:

- Shipping and Freight: Heavy machines can cost several hundred dollars to ship. Always get a full delivered price.

- Installation: Complex machines may require professional installation and electrical work, costing $200-$500+.

- Maintenance and Repairs: Budget for regular maintenance and eventual replacement parts. Access to reliable service and preventative maintenance guidance from reputable sources, such as the National Restaurant Association, can minimize downtime.

- Energy Consumption: Factor the electricity use of automatic models into your operating costs.

To reduce your total investment, compare quotes from multiple suppliers, ask about bulk discounts, and prioritize a comprehensive warranty. Don't hesitate to negotiate shipping costs. If the upfront cost is a concern, explore financing options. Many suppliers offer programs, like the pizza restaurant financing available through PizzaPrepTable.com, to help you manage the expense.

Keeping Your Cutter in Prime Condition: Maintenance and Safety

A commercial dough cutter is a workhorse, but it requires regular care to run safely and efficiently. Neglecting maintenance can lead to breakdowns, inconsistent results, and safety hazards for your team.

Daily Cleaning: A solid cleaning routine is crucial. After each shift, wipe down all surfaces with a damp cloth and food-safe cleaner. Never spray water directly onto the machine, as it can damage electrical components. Remove and wash all detachable parts like blades and trays, ensuring they are completely dry before reassembly. Use a plastic scraper for stubborn residue to avoid scratching surfaces.

Regular Maintenance: Moving parts need lubrication to prevent wear. Check your manual for the recommended schedule and type of food-grade lubricant. Inspect blades daily for sharpness and damage. Dull blades strain the motor and produce poor cuts; have them professionally sharpened or replaced as needed.

Safety Protocols: Safety is paramount. Always unplug the machine or turn off the circuit breaker before any cleaning or maintenance. Ensure all safety guards are in place and that your team knows the location of the emergency stop buttons. The machine should be properly grounded with appropriate circuit breakers. During operation, keep hands and loose clothing away from all moving parts. Following these procedures and including them in your commercial kitchen equipment checklist will ensure a safe and efficient work environment.

Frequently Asked Questions about Commercial Dough Cutters

Here are answers to the most common questions we hear from pizzeria owners and bakers.

How do I choose the right size dough cutter for my business?

Choosing the right size is crucial to avoid production bottlenecks or wasted money. First, assess your peak production volume—how many dough portions do you need per hour? Next, consider the types of products you make and ensure the machine's portion weight range matches your recipes. An adjustable commercial dough divider cutter offers great flexibility. Finally, measure your available kitchen space carefully, leaving clearance for operation and cleaning.

How do I adjust the portion weight on a dough divider?

Adjusting the weight is usually straightforward. Manual dividers often use interchangeable pressure plates or inserts to change portion size. Semi-automatic models typically have a dial or lever to set the desired weight before you process a batch. High-end automatic dividers feature digital controls or touch screens where you can input the exact weight, and many allow you to save presets for different products. Always consult your user manual for specific instructions.

What's the difference between a dough divider and a dough rounder?

These two machines perform distinct but related tasks. A dough divider cuts a large dough mass into smaller, equal-weight portions. Its job is to ensure precision and consistency for even baking. A dough rounder takes those divided portions and shapes them into smooth, uniform balls. This rounding process creates a skin on the dough that traps gases during proofing, leading to a better rise and texture.

Many modern machines are divider-rounders, which combine both functions into one streamlined process. These are game-changers for high-volume operations, saving time, labor, and space. You might start with a divider-only machine and round by hand, but as your business scales, the combination functionality becomes incredibly valuable.

Conclusion

By now, you should have a clear understanding of how a commercial dough cutter can revolutionize your kitchen. These machines are game-changers, delivering measurable benefits in efficiency, consistency, and labor savings. The right cutter helps control portions, cut waste, and protect your profit margins.

We've explored the options, from simple manual tools to sophisticated automatic divider-rounders. The key is to choose a machine that fits your production volume and budget. Prioritizing features like food-grade stainless steel construction and NSF certification is a wise investment in durability and hygiene. Remember to consider the total cost of ownership, including shipping, maintenance, and potential financing.

At PizzaPrepTable.com, we are more than just a supplier; we are partners in your success. We offer a wide selection of commercial pizza prep tables and other essential equipment to fit your needs. Our flexible financing options make it possible to get the right tools without breaking your budget.

Choosing the right commercial dough cutter means matching the machine to your operational needs. Ready to upgrade your dough production? Explore our range of commercial kitchen equipment at PizzaPrepTable.com. And for more tips, check out our essential guide to the best pizza cutters—because precision matters at every step.