Finding the Perfect Small Prep Table for Your Space

Share

Why Every Commercial Kitchen Needs the Right Small Prep Table

A small prep table is the backbone of any efficient commercial kitchen, providing dedicated workspace that keeps your food preparation organized and sanitary. Whether you're running a food truck, small pizzeria, or cafe, the right prep table can transform your workflow and help you meet health code requirements.

Key benefits of small prep tables:

- Space efficiency - Fits in kitchens as small as 20-30 square feet

- Improved workflow - Dedicated prep space reduces cross-contamination

- Versatile storage - Undershelves and drawers keep tools organized

- Easy mobility - Caster wheels allow flexible kitchen layouts

- Hygienic surfaces - Stainless steel meets NSF commercial standards

Small prep tables typically range from 24 to 48 inches in width, making them perfect for tight spaces while still providing ample workspace. The most popular sizes are 24" x 36" and 30" x 24", which offer the ideal balance of functionality and space savings.

Weight capacities vary by model:

- Top shelf: 200-600 lbs

- Undershelf: 100-400 lbs

I'm Sean Kearney, and my background in sales has taught me that having the right small prep table can make the difference between kitchen chaos and smooth operations. From working with food truck owners to helping cafes maximize their limited space, I've seen how the right equipment transforms businesses.

The Benefits of a Dedicated Prep Space

During a lunch rush, a proper small prep table can mean the difference between chaos and a rhythmic workflow. Without a designated prep area, staff bump into each other, ingredients get scattered, and operations become a scramble. A small prep table creates an improved workflow that keeps everyone moving in harmony.

When a prep cook has their own space for chopping vegetables, they aren't competing with the line cook plating orders. Each person has their zone, tools are within reach, and work flows naturally. This dedicated workspace means faster prep times and happier staff, which translates to better customer service.

Improved hygiene is critical. Cross-contamination is a business killer, and prepping raw chicken and then assembling salads on the same surface is a major risk. A dedicated small prep table allows you to separate these tasks completely.

You can designate one table for raw proteins and another for vegetables, or use it exclusively for ready-to-eat items. This reduced cross-contamination keeps customers safe and your business protected—an investment that pays for itself by preventing a single foodborne illness incident.

Organization is a secret weapon for efficiency. Quality prep tables with undershelves or drawers give your tools and ingredients a home right where you need them.

No more hunting for tools across the kitchen. With everything in its place, your team spends more time cooking, leading to increased output.

The versatility of a well-chosen small prep table is invaluable. It can be a mixing station for breakfast, a sandwich assembly line for lunch, and a plating area for dinner.

This adaptability is crucial in small kitchens where every square foot counts. A multi-functional piece of equipment is smart business. For more insights on maximizing your prep table investment, check out our comprehensive guide on restaurant kitchen prep tables.

The bottom line? A dedicated prep space is essential for any kitchen to operate at its full potential. For a food truck or a small cafe, a small prep table is the foundation for success.

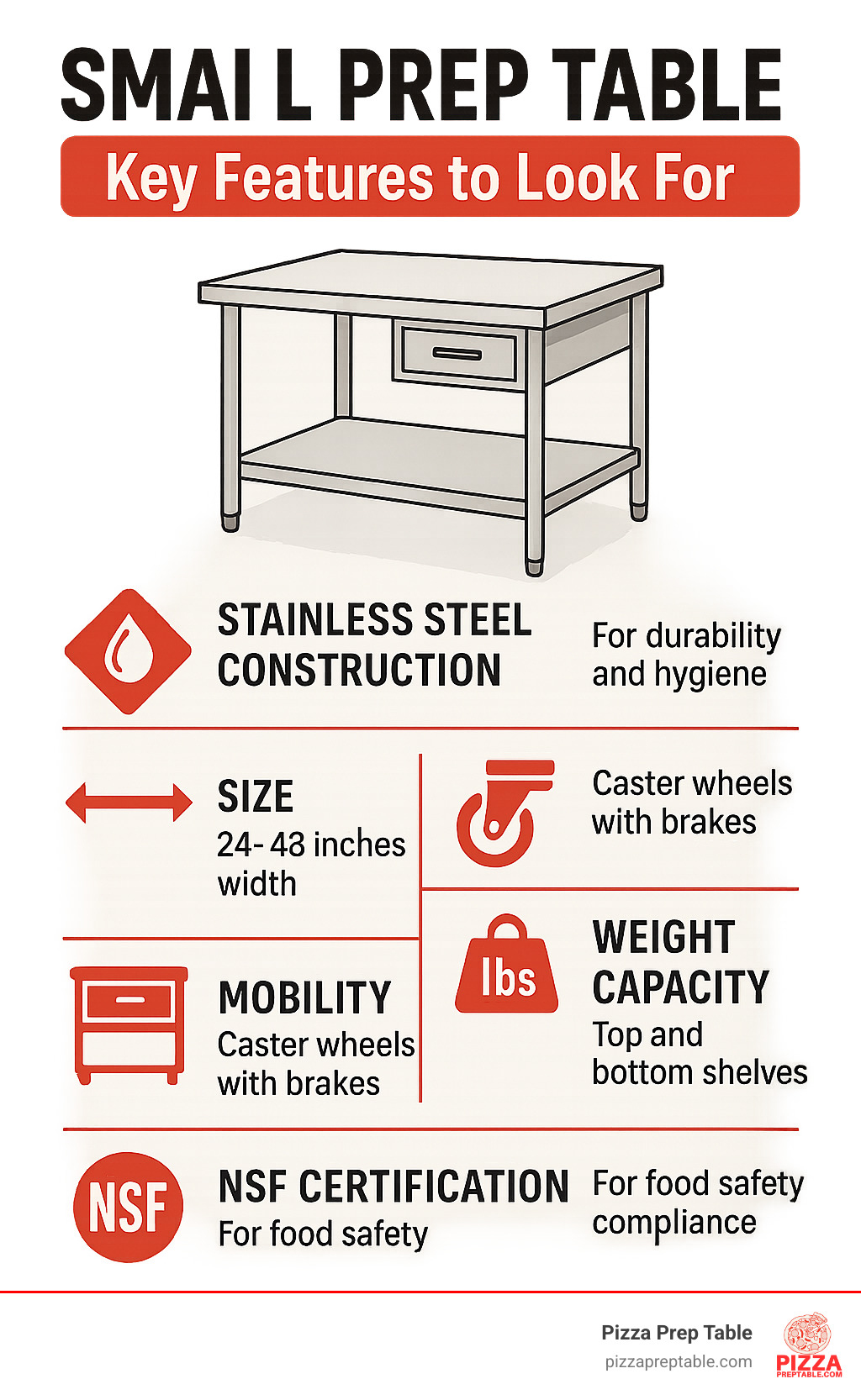

Key Features to Look For

Finding the perfect small prep table doesn't have to be overwhelming. Let's walk through what really matters when you're making this important investment for your kitchen.

Material Matters for a Durable Small Prep Table

In a commercial kitchen, a prep table must withstand knife work, heavy bowls, hot pans, and constant cleaning. The right material is everything.

Stainless steel is the clear winner, and for good reason. Beyond its professional look, it offers incredible durability that withstands years of daily punishment, from dropped pots to knife scrapes.

Its corrosion resistance prevents rust in humid, splash-heavy kitchen environments, which is crucial for small prep tables that may be moved or stored in tight, moist spaces.

The key benefit is hygiene. Stainless steel's non-porous surface prevents bacteria growth, making it easy to sanitize. This ensures you pass health inspections and keep customers safe. Learn more in our guide Slice-in-Style-Choosing-a-Stainless-Steel-Pizza-Prep-Table.

When shopping, look for NSF certification. This approval from the National Sanitation Foundation confirms the table meets strict public health standards and is often a mandatory requirement for commercial kitchens.

Regarding steel gauge, lower numbers mean thicker steel. 16-gauge steel is more robust than 18-gauge. For most small prep table uses, 18-gauge offers a good balance of durability and price. For heavy-duty use, 16-gauge is a worthwhile investment.

Size, Storage, and Mobility

Getting the size right is crucial for comfort and workflow. Small prep tables typically range from 24 to 48 inches in width, but the right size is relative to your kitchen's needs.

Measure your available space, accounting for workflow clearance for doors, staff, and other equipment. A table that fits but creates a bottleneck is more frustrating than helpful.

Weight capacity is crucial for both safety and longevity. Top surfaces typically handle 200-600 pounds, while undershelves manage 100-400 pounds. Think about what you'll actually be doing—heavy mixing, large stockpots, or just light prep work. Choose a table that can comfortably exceed your heaviest anticipated load.

Storage options can transform a simple table into a workspace powerhouse. Undershelves are fantastic for storing pots, ingredient containers, or small appliances, keeping your work surface clear while maintaining easy access. Some models offer drawers for organizing utensils, towels, and smaller items that tend to create clutter.

Mobility features add incredible flexibility. Tables with wheels (casters) let you reconfigure your kitchen layout, move the table for deep cleaning, or even relocate it for special events. Locking casters are essential—once you've positioned your table, those locks ensure it stays put during active prep work.

If mobility isn't a priority, adjustable feet help level your table on uneven floors, preventing wobbles that can make precision work frustrating. A backsplash—that vertical lip at the back—prevents spills from reaching your wall and stops ingredients from rolling off the back edge.

Special Features for Specific Tasks

While a basic small prep table is versatile, specialized features can boost efficiency for specific operations. These are productivity boosters that transform how you work.

Refrigerated bases are game-changers for delis and sandwich shops. With cold storage right beneath the work surface, you eliminate trips to the walk-in cooler. Ingredients stay at safe temperatures, speeding up assembly and improving food safety. Learn more in our Cool-Picks-Best-Refrigerated-Prep-Tables guide.

Some tables feature integrated sinks built right into the work surface. These are incredibly handy for tasks requiring frequent rinsing—think produce prep or beverage stations. Having water access without leaving your prep area keeps workflow smooth and reduces cross-contamination risks.

Cutting board surfaces made from durable polyethylene provide a dedicated chopping area that protects your stainless steel surface from knife damage. It's like having your favorite cutting board permanently installed and perfectly sized. For expert advice on choosing the right cutting surfaces, explore our Cutting-Edge-Choices-Best-Pizza-Prep-Table-Cutting-Boards article.

Topping rails are essential for pizza and sandwich shops. These refrigerated wells hold pans of toppings, keeping everything chilled and accessible for fast assembly. A topping rail quickly pays for itself through improved efficiency.

The key is matching features to your needs. A food truck may need mobility, while a sandwich shop benefits from refrigeration. Choose features that solve real problems in your operation.

Our Top Picks for the Best Small Prep Table

The best small prep table fits your specific needs and budget. Here are our top selections to help you find the perfect fit for your kitchen.

Let me walk you through my favorite picks, each chosen for different kitchen situations I've encountered over the years.

Best Overall: The All-Rounder

For an all-rounder that excels in busy kitchens, we recommend the Regency 24" x 36" 16-Gauge Stainless Steel Commercial Work Table with 4" Backsplash and Undershelf. It's a true workhorse.

It's built with 16-gauge type 304 stainless steel, making it thicker and more durable than standard 18-gauge models. It can handle heavy equipment and constant use without showing wear.

The NSF certification gives you peace of mind for health inspections, while the adjustable undershelf provides flexible storage. That 4-inch backsplash is a lifesaver for keeping walls clean and containing spills.

With a 560-pound top shelf capacity and 340-pound undershelf capacity, this table can handle everything from heavy mixers to full ingredient containers. Its stability is consistently praised, with users noting it can handle multiple mixers without wobbling.

Assembly is straightforward, and at around $200-300, it offers exceptional value for money and pays for itself through years of reliable service.

Best on a Budget: Quality without the High Cost

For new kitchens or tight budgets, the Empura 36" x 24" Economy Work Table proves you don't have to sacrifice quality.

This small prep table features an 18-gauge 430 stainless steel top, providing excellent durability for most tasks. While less corrosion-resistant than 304 steel, it's suitable for general prep. The galvanized steel legs and undershelf keep costs down while maintaining structural integrity.

The flat top design without a backsplash keeps things simple and affordable. Those adjustable plastic feet ensure your table stays level even on uneven floors—a common issue in older buildings or food trucks.

This table shines in light-duty applications like sandwich assembly, general prep work, or as an additional workspace during busy periods. It's popular with cafes, small bakeries, and startups who need reliable equipment without the premium price tag. For more budget-friendly restaurant equipment options, check out our guide on Prep-Tables-for-Restaurant.

Most Versatile: The Mobile Workstation

For food trucks and caterers who need flexibility, the VEVOR 24" x 24" Mobile Prep Table is our go-to recommendation for a small prep table that adapts to any situation.

Its heavy-duty casters with reliable brakes allow you to roll it anywhere and lock it securely for stable prep. The durable wheels won't flatten, and the brakes hold firm during intensive work.

Made from durable stainless steel, this compact powerhouse supports up to 400 pounds on top and 200 pounds on the undershelf. The adjustable height feature is brilliant for ergonomic comfort, especially when different team members use the same station.

At just 24" x 24", this table fits into tight spaces while providing maximum functionality. It works perfectly as a mobile prep station, a serving cart, or even a temporary bar setup. The assembly manual shows just how straightforward the setup is.

This table is ideal for food trucks where space is premium and flexibility is everything. It's also perfect for catering operations that need equipment they can quickly reconfigure for different events.

Best for Sandwiches and Salads

Deli and sandwich shops need ingredients both cold and accessible. A standard small prep table isn't enough; a refrigerated unit like the Atosa 27" Sandwich Prep Table is essential.

This specialized unit combines a refrigerated base with a convenient work surface, keeping your meats, cheeses, and vegetables at safe temperatures while you assemble orders. The food pan capacity allows you to organize ingredients logically, speeding up service during rush periods.

Most models include a cutting board surface, giving you a dedicated area for slicing without damaging the stainless steel top. The compact 27-inch width fits perfectly in smaller delis and cafes without overwhelming the space.

The efficiency of these units is their real beauty. With everything chilled and within reach, you get faster service, better food safety, and happier customers. Explore these units in our guide on Sandwich-Prep-Table-Refrigerator.

If your business revolves around fresh sandwiches, salads, or subs, this type of small prep table is absolutely essential for maintaining quality and speed.

How to Care for Your Small Prep Table

Your small prep table is a hardworking foundation of your kitchen. Proper care protects your investment, maintains food safety, and ensures long-term reliability.

The golden rule is daily cleaning. At the end of each shift, wipe the table with warm water, mild detergent, and a soft cloth. This prevents buildup of grease and food particles that become harder to remove later.

Sanitizing surfaces is non-negotiable for food safety. After cleaning, always use a food-safe sanitizer, especially after handling raw ingredients. This keeps customers safe and health inspectors happy. Let the surface air dry or use a clean cloth.

Stainless steel care requires a gentle touch. To prevent water spots, dry your small prep table immediately after rinsing. For deeper cleaning, use a quality stainless steel cleaner, wiping in the direction of the grain. Avoid harsh chemicals or abrasives that could scratch the surface and compromise its corrosion resistance.

For light surface marks, a stainless steel scratch removal kit can often make minor scratches nearly invisible. Deeper gouges might need professional attention, but prevention is always your best strategy—use cutting boards consistently and handle sharp tools with care.

If your small prep table has wheels, don't forget about checking casters regularly. Clean away any food debris and test the locking mechanisms to ensure your table stays put. A little lubrication, following manufacturer guidelines, keeps everything rolling smoothly.

Periodically inspect undershelves, legs, and any bolted connections. Vibrations from daily use can loosen hardware, so tighten any loose bolts promptly. Keep an eye out for any signs of rust or wear, especially on galvanized components.

This routine ensures the long-term durability and hygiene of your equipment. A well-maintained table is a reliable partner in your daily operations. For more insights, see our guide on Prep-Tables-that-Work-as-Hard-as-You-Do.

A clean kitchen isn't just good business—it's the foundation of great food and happy customers!

Frequently Asked Questions about Prep Tables

Here are answers to the most common questions we receive about prep tables.

How do I choose the right size prep table for my kitchen?

Choosing the right size small prep table is crucial. Many owners buy a table that's too large for their space or workflow.

Start with your tape measure. Measure the intended space, plus doorways, stairwells, and tight corners for delivery. Remember to factor in walking room and space to work around the table.

Next, think about your daily workflow. How many people will use it? Do you need space for large bowls or sheet pans? A cramped station slows service. Plan for your busiest day to ensure the table is adequate.

Consider your other equipment too. Your small prep table should create a logical path with your existing setup, not an obstacle course.

Finally, think ahead. If you plan to expand your menu, a slightly larger table might save you from buying twice. However, be realistic about the constraints of your small space.

Can I put heavy equipment on my prep table?

This is a critical safety question. Always check the manufacturer's specified weight capacity for both the top shelf and undershelf. These are engineering limits designed for safety.

Exceeding the weight capacity can lead to bending, wobbling, or complete failure. Ignoring these limits can result in costly damage to equipment.

For heavy appliances like mixers, ensure the table is not only within its weight limit but also stable and level. If your table has adjustable feet, make sure they're properly positioned to prevent wobbling. If it has wheels, lock those casters before placing any heavy equipment on top.

Most quality small prep tables can handle surprisingly heavy loads—some support 400-600 pounds on the top shelf. A good rule of thumb is to stay well under the maximum capacity, especially if you'll be doing any vigorous mixing or kneading that creates additional force.

What does NSF Listed mean and why is it important for a commercial kitchen?

NSF stands for National Sanitation Foundation. An "NSF Listed" mark on a small prep table is a certification of safety and cleanliness, not a marketing gimmick. It means the equipment has passed rigorous, independent testing.

NSF tests ensure that materials won't leach chemicals, the design allows for easy and thorough cleaning, and the construction meets strict durability standards. It's a comprehensive health and safety exam for equipment.

Why is it important? It's often required by health departments. Beyond compliance, NSF certification means the equipment is designed for the demanding environment of a commercial kitchen.

NSF Listed equipment is generally built to higher standards, which means it'll last longer and perform better. It's also easier to clean and sanitize properly, which protects your customers and your reputation. When choosing a small prep table, NSF certification is essential peace of mind.

Conclusion

Choosing the right small prep table is a strategic investment in your kitchen's productivity, efficiency, and safety. By carefully considering the material (stainless steel is best), dimensions, and special features for your specific tasks, you can find a unit that will be an indispensable part of your operation for years.

From boosting workflow to ensuring top-tier hygiene, a well-chosen small prep table supports your team through every service. It helps keep customers safe and protects your reputation.

At PizzaPrepTable.com, we are more than equipment suppliers; we are your partners in success. We understand the challenges pizzerias and foodservice businesses face, from optimizing a tiny food truck kitchen to improving flow in a busy pizzeria. We know how crucial the right equipment is.

That's why we offer a wide selection of small prep tables and flexible financing options to fit any space and budget. We help businesses of all sizes slice, dice, and prep their way to success. Great food starts with great preparation, which starts with the right tools.

Ready to transform your kitchen and take your prep game to the next level? Explore our full range of Sandwich and Salad Prep Tables to find your perfect match. Your future self (and your kitchen team) will thank you!