Mastering Food Safety Temperature Logs in Your Pizzeria

Share

Food safety temperature logs are the unsung heroes of a busy pizzeria. They're the simple, day-to-day records that document the temperature of your equipment and food, from the walk-in cooler to the pizza prep table. Think of them as proof—undeniable evidence that every topping, from pepperoni to mozzarella, is held at a safe temperature to stop harmful bacteria in its tracks.

This isn't just about ticking a box for the health inspector; it's a fundamental part of a solid food safety program designed for the unique demands of a pizzeria.

Why Accurate Temperature Logs Are Crucial for Pizzerias

Picture the dinner rush on a Friday night. It's controlled chaos. You've got dough flying, orders being shouted, and the pizza oven roaring. In the middle of all that, the single most important tool protecting your business isn't the oven—it's your food safety temperature log. These logs are more than just a chore; they are your frontline defense against the kind of real-world risks that can permanently tarnish a pizzeria's reputation.

Imagine a slight temperature slip on a pizza prep table loaded with everything from pepperoni and sausage to fresh mozzarella and sliced mushrooms. This is where the temperature "danger zone" becomes a very real problem for pizzerias.

Understanding the Danger Zone in a Pizzeria

The temperature danger zone is that critical range where bacteria don't just survive—they thrive, multiplying at an alarming rate. Pizza prep tables are especially vulnerable. They're constantly being opened during service, and their location right next to blazing hot pizza ovens creates an ambient temperature that’s always fighting against your refrigeration.

The U.S. Food and Drug Administration (FDA) Food Code is clear: cold foods must be held at or below 41°F (5°C). What's even more concerning is that some research shows the most rapid growth for many pathogens happens between 86°F and 115°F (30°C to 46°C). That’s a temperature your pizza toppings can hit surprisingly fast if left unchecked on a busy make-line.

A consistent temperature log is more than just a piece of paper; it's a narrative of your commitment to safety. It tells a story to health inspectors, your staff, and your customers that you prioritize their well-being above all else.

Beyond Compliance to Building Trust

Keeping meticulous food safety temperature logs shows a level of professionalism that builds trust and protects your brand. A single foodborne illness outbreak traced back to your pizzeria can be devastating, causing not just financial loss but irreparable damage to your standing in the community.

Here's why diligent logging is non-negotiable for a pizza shop:

- Early Problem Detection: Regular checks can spot a failing pizza prep table compressor or a walk-in that’s struggling before it leads to thousands of dollars in spoiled cheese and meats.

- Staff Accountability: When your pizza makers have to initial every log entry, it creates a culture of ownership. Food safety becomes everyone's responsibility.

- Liability Protection: If a food safety complaint ever arises, well-maintained logs are your concrete evidence of due diligence, showing you took every reasonable precaution.

Ultimately, this isn't just about avoiding fines. It's the bedrock of a safe, successful, and trustworthy pizzeria and a core piece of your restaurant's overall food safety guidelines for restaurants.

Building a Practical Temperature Logging System

Let's be honest: if your temperature logging system is a pain to use, your pizza crew won't follow it. A bulletproof system isn't about complexity; it’s about making the process practical, consistent, and so simple it becomes an ingrained habit. This whole process kicks off by walking through your pizzeria and identifying every single spot where temperature is critical to keeping your ingredients safe.

You're essentially mapping out your kitchen's critical control points (CCPs). These are the key areas where a temperature slip-up could turn safe pizza toppings into a serious problem. The goal is simple: leave no refrigerated unit unchecked.

Pinpointing Your Pizzeria's Critical Control Points

Every pizzeria has its own unique layout, but the usual suspects for CCPs are pretty consistent. Grab a notepad and start making a list of every piece of equipment that needs its temperature monitored.

Your list will probably look something like this:

- Walk-In Cooler: The mothership. This is where you're storing bulk cheese, cases of pepperoni, tubs of sauce, and trays of proofing dough.

- Reach-In Refrigerators: These units are for the prepped items, backup ingredients, and maybe drinks.

- Low-Boy or Under-Counter Coolers: Tucked under the counters, these hold the backup sauces and prepped items you need to grab fast during service.

- The Pizza Prep Table: This is your most active—and most vulnerable—CCP. Toppings sit here for hours, constantly exposed to the ambient heat of the kitchen and the pizza oven.

Once you have your list of every single unit, it's time to set a realistic schedule. A log that demands checks every hour is just going to get pencil-whipped. One that's too infrequent leaves you blind to potential problems.

A great place to start is logging temperatures three times daily: once before the morning prep shift gets going, again during the mid-day changeover or before the dinner rush, and a final check at closing. This gives you a snapshot of the entire operational day.

It's a classic mistake to think that just having thermometers is enough. A recent survey found that while 88.1% of restaurants use thermometers, a shocking 13% actually kept regular temperature records. Building a reliable system is what closes that dangerous gap. You can get into the nitty-gritty in the full study on restaurant temperature monitoring practices.

Designing Your Pizzeria's Log Sheet

Whether you go old-school with a clipboard or use a digital app, the log sheet itself needs to be dead simple. Overly complicated forms just create friction and encourage your team to take shortcuts.

Make sure your log has clear, simple columns for the essential info:

- Equipment Name: Be specific (e.g., "Main Pizza Prep Table," "Walk-In").

- Date & Time: Crucial for tracking when the check actually happened.

- Temp (°F): The actual temperature you see on the thermometer.

- Employee Initials: This creates accountability for every single check.

- Corrective Actions: A spot to jot down what went wrong and what was done about it (e.g., "Prep table temp at 45°F. Rotated pans, door seal checked.").

This straightforward format gives a health inspector everything they need to see at a glance and makes the task clear and direct for your pizza crew. To make things even smoother, stick a calibrated, easy-to-read thermometer right near each CCP.

By focusing on these fundamentals, you turn temperature logging from a dreaded chore into one of your most powerful tools for protecting your customers and your pizzeria.

Mastering Daily Checks on the Pizza Prep Line

It's one thing to talk about food safety in a quiet kitchen, but it's another thing entirely during the chaos of a Friday night dinner rush. This is where your temperature logs stop being a checklist and become a live tool for managing the hottest spot in your operation: the pizza prep line. With lids constantly opening and closing right next to blazing hot pizza ovens, this area is ground zero for temperature abuse.

Keeping those pizza toppings safely chilled when the prep rail lid is open more than it's closed is a constant battle. The secret isn't a fancier fridge; it's building smart habits into your team's muscle memory. This turns reactive panic into proactive control, and it starts with knowing your pizza prep table inside and out.

Proactive Strategies for the Pizza Prep Line

Seasoned pizzeria operators know that holding temp isn't just about the compressor's power—it's about process. Your team can actively manage the prep line environment with a few proven techniques that make all the difference when you're slammed.

These are simple, actionable steps that help your crew work with the equipment, not against it:

- Strategic Pan Rotation: Don't just top off the pepperoni pan. Rotate it. The topping pans at the front of the line (or closest to the oven) take the most heat, so swap them with fresh, colder pans from the walk-in. The "older" pans can then move to the back of the rail where it's colder. This simple move ensures no single pan of mushrooms sits in the hot seat for too long.

- Understanding Recovery Time: Every pizza prep table has a temperature recovery time—the time it needs to get back down to temp after the lids have been open. Train your pizza makers to close the lids during any lull, even if it's just for 30-60 seconds. That short break gives the unit a chance to catch its breath and pull the temperature back down.

- Using Ice Wands: For those emergency moments when an ingredient is creeping into the danger zone, a pre-frozen ice wand is your best friend. It can bring the temperature of a topping pan back down fast without you having to throw out the product. A solid foundation of food safety training for employees that covers these real-world scenarios is absolutely essential.

Quick Reference for Pizza Topping Temperatures

To give your team an immediate, no-nonsense guide, a reference chart posted right at the pizza prep table is invaluable. It takes the guesswork out of the equation and reinforces the most critical rule: keep every single topping at or below 41°F (5°C).

The most effective food safety systems are the ones that are easiest for a busy pizza crew to follow. Posting a clear temperature chart directly in the line of sight turns a complex requirement into a simple, visual reminder that becomes second nature.

Here’s a quick-reference guide I recommend for the most common ingredients you'll find on any pizza prep table. It breaks down not just the what, but the why.

Ideal Holding Temperatures for Common Pizza Prep Table Ingredients

This table is a simple, visual tool to help your team instantly recognize safe temperatures and understand the specific risks associated with each ingredient category on the pizza line.

| Ingredient Category | Examples | Safe Holding Temperature (°F) | Safe Holding Temperature (°C) | Key Safety Consideration |

|---|---|---|---|---|

| Processed Meats | Pepperoni, Sliced Ham, Salami | At or below 41°F | At or below 5°C | High fat content can mask initial spoilage. Strict temperature control is essential. |

| Cooked Meats | Sausage, Grilled Chicken, Bacon | At or below 41°F | At or below 5°C | As a cooked item, it's a prime target for bacterial growth if temperature control fails. |

| Dairy Products | Shredded Mozzarella, Provolone | At or below 41°F | At or below 5°C | Cheese has a high moisture content, making it susceptible to rapid bacterial growth above 41°F. |

| Cut Vegetables | Onions, Bell Peppers, Mushrooms | At or below 41°F | At or below 5°C | Once cut, the natural protective barrier is gone, increasing vulnerability to contamination. |

Having this information posted clearly helps eliminate any ambiguity during a busy shift. When a team member sees the temp on a pan of shredded mozzarella creeping up to 45°F, they know instantly that it’s time to take action.

Responding Effectively to Temperature Issues

Seeing a 45°F reading on your pizza prep table log can send a jolt of panic through any manager. But having a clear plan transforms that anxiety into quick, decisive action. A temperature deviation isn't a failure; it's a totally expected challenge in a busy pizzeria. How you respond is what really defines your commitment to food safety.

The goal here is to empower your pizza crew with a simple, no-nonsense framework. There's zero room for guesswork when customer safety is on the line. Your playbook should be dead simple: figure out what went wrong, decide the fate of the food, and document every single thing.

Investigate and Act Immediately

The second a crew member logs a temperature above the safe zone of 41°F (5°C) on the pizza prep table, a two-step process needs to kick in automatically. First, they need to play detective and hunt for the root cause. Is it an easy fix or something more serious?

On a busy pizza line, the usual suspects are pretty common:

- Blocked Air Vents: A stray piece of plastic wrap or a misplaced topping pan can easily choke off the cold airflow, causing one part of the prep table to warm up.

- Overfilled Pans: Mounding toppings high above the fill line is a classic mistake. It stops cold air from circulating over the food, leaving the ingredients on top to warm up.

- A Door Left Ajar: During a big rush, it’s easy for a low-boy cooler door under the prep table to not shut completely, forcing the compressor to work overtime and struggle to keep up.

- Failing Equipment: If the simple fixes don’t solve the problem, you might be staring at a bigger issue like a faulty thermostat or a compressor that's on its last legs.

Next, based on what they find, they have to act. This is where the critical "save or discard" decision comes into play.

The rule of thumb is simple and non-negotiable: when in doubt, throw it out. The cost of a few pans of shredded cheese is nothing compared to the fallout from a foodborne illness outbreak and the hit your pizzeria's reputation would take.

The Save or Discard Decision

So, can you save the food? If a pizza topping has been in the temperature danger zone (anything above 41°F) for less than two hours and you've fixed the equipment issue, it might be salvageable. For instance, if you can get the temperature back down into the safe zone rapidly, the food could be okay.

This is where equipment like a commercial blast chiller can be a lifesaver. Our guide on choosing a commercial blast chiller dives into how this tech can be a huge asset to your food safety protocols.

However, if the food has been in the danger zone for more than two hours, or if you have no idea how long it's been out of temp, it must be discarded. No exceptions. This isn't just a best practice; it's a hard-and-fast safety rule. This standard is constantly being reinforced by food safety authorities worldwide who are tightening temperature guidelines to better control pathogen growth. For example, recent advice now urges keeping consumer fridges below 4°C, underscoring the known risks of bacteria like Salmonella. You can read more about these updated refrigerator temperature study findings.

Finally, document every step in your food safety logs. Note the out-of-range temperature, the time it was discovered, the root cause you identified (e.g., "blocked air vent on pizza prep table"), the corrective action you took ("cleared vent, temp returned to 38°F"), and exactly which products were thrown out. This creates a bulletproof record for health inspections and helps you spot recurring equipment problems before they become catastrophes.

Choosing Between Paper Logs and Digital Systems

Once you’ve nailed down how and when your pizza team will be doing temperature checks, the next big question is what tool you'll use to record them. Are you sticking with the classic clipboard and pen, or is it time to bring your logs into the digital age?

Honestly, there’s no single right answer here. The best choice really depends on your pizzeria’s specific workflow, how comfortable your crew is with tech, and, of course, your budget.

The Case for Old-School Paper Logs

There’s a certain appeal to the simplicity of paper logs. They require basically zero training, have no startup cost, and you can roll them out in about five minutes. A printed sheet, a pen, and a clipboard are all it takes to get going, which is a huge plus for any new pizzeria trying to keep things simple.

But that simplicity comes with some real-world headaches. Handwriting can be a nightmare to decipher during a health inspection. Sheets get splattered with sauce, go missing on a busy prep line, or end up as a crumpled mess. And let's not forget the stacks of binders you'll need to store to meet record-keeping requirements. Trying to spot a recurring issue with a cooler? Good luck flipping through weeks of handwritten logs to find a pattern.

Why Digital Food Safety Logs Are Taking Over

This is where digital systems, from simple apps on a phone to fully automated wireless sensors, really change the game. Yes, they come with an initial hardware cost or a subscription fee, but for a busy pizzeria, the benefits can quickly make that cost a no-brainer.

Here’s what you gain by going digital:

- Instant Alerts: Imagine your pizza prep table starts creeping into the danger zone. Instead of finding out hours later, a digital system can shoot an immediate text or email to a manager. This lets you jump on the problem before you have to throw out hundreds of dollars in cheese and toppings.

- Cloud Storage: Health inspector shows up? No more frantic searches for that one missing binder from three months ago. All your records are securely stored in the cloud, ready to be pulled up on a tablet or phone in seconds.

- Data That Actually Helps: Digital logs make it incredibly easy to see trends. You can spot if a specific cooler or pizza prep table is consistently running a degree or two warm, flagging a maintenance issue before the compressor gives out completely on a Friday night.

- Better Accountability: Digital entries are typically timestamped and tied to a specific user. This creates a clear, tamper-proof record of who did what, and when.

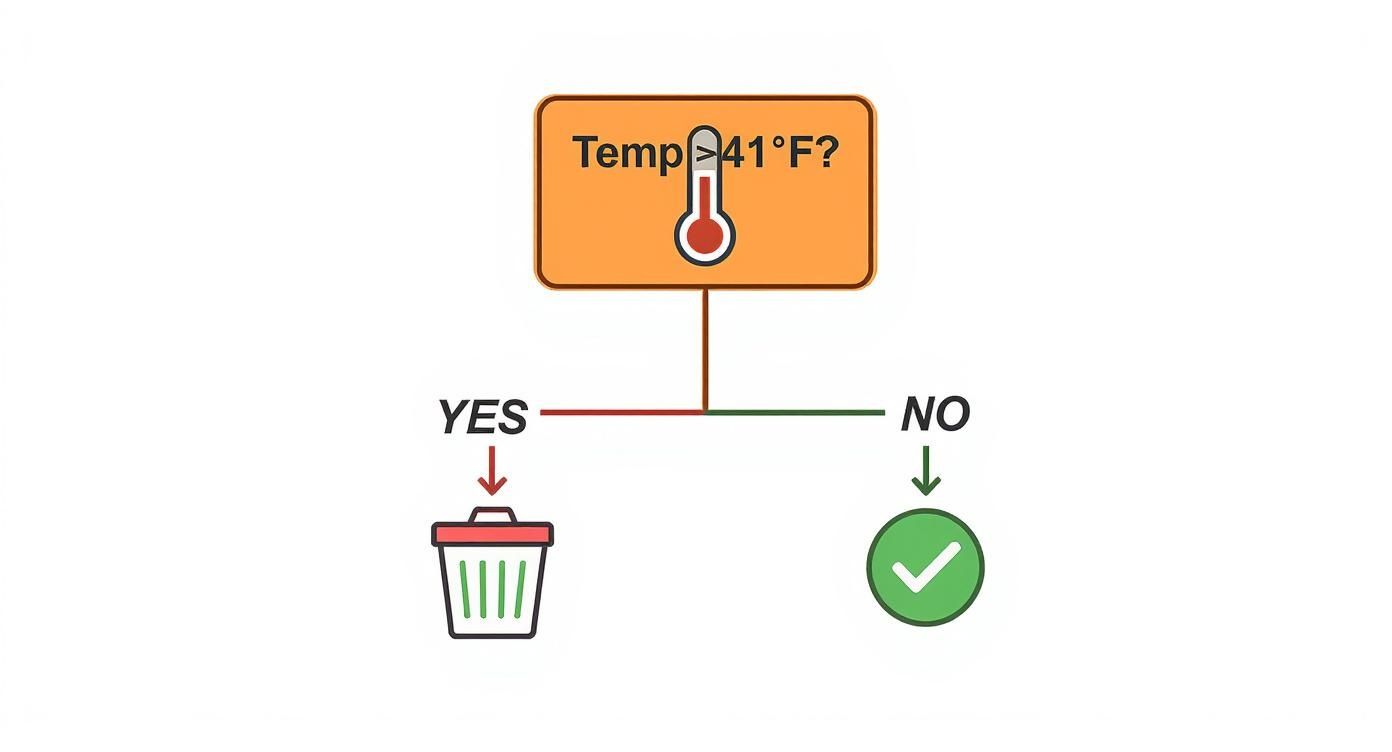

This simple decision tree illustrates the critical choice your team makes every time a temperature is off—a process that digital alerts make faster and nearly foolproof.

This visual drives home the one rule that never changes: any temperature reading above 41°F (5°C) demands immediate action. Digital systems help enforce that rule automatically.

Paper vs. Digital Food Safety Temperature Logs

To help you weigh the options, let’s break down how traditional paper logs stack up against modern digital systems in a real-world pizzeria setting.

| Feature | Paper Logs | Digital Logs |

|---|---|---|

| Startup Cost | Virtually zero. Just a printer and a pen. | Initial hardware costs or subscription fees. |

| Ease of Use | Extremely simple. Almost no training needed. | Can have a slight learning curve for staff. |

| Data Accessibility | Stored physically. Can be lost or damaged. | Secure cloud storage. Accessible anywhere, anytime. |

| Alerts & Notifications | None. Relies on staff noticing an issue. | Instant SMS/email alerts for out-of-range temps. |

| Data Analysis | Manual and time-consuming. Hard to spot trends. | Automated reports show equipment performance & trends. |

| Accountability | Relies on legible handwriting and honesty. | Timestamped, user-specific entries are tamper-proof. |

| Record Retrieval | Requires physically finding and sorting binders. | Instant search and retrieval for health inspections. |

While paper is easy to start with, the long-term benefits of digital—like preventing product loss and flagging equipment failures—often provide a much higher return on investment for a pizzeria.

Making the Right Choice for Your Pizzeria

Ultimately, this decision is a cost-benefit analysis for your specific operation. A small, single-location pizza shop might get by just fine with a well-organized paper system. But a growing pizzeria, maybe with a second or third location on the horizon, will find the consistency and oversight of a digital system invaluable.

The best system is the one your team will actually use consistently. Whether it’s a perfectly organized binder or a user-friendly app, consistency is the key to a successful food safety program.

Before you commit, see if you can get a trial period with a digital provider. You could even run both systems side-by-side for a week. See which method causes less friction for your staff and gives you, the owner, the most peace of mind.

Got Questions About Your Pizzeria Temp Logs? We’ve Got Answers.

Even with a solid logging system in place, the chaos of a busy pizza rush can throw some real-world curveballs. These are the moments that can leave even a seasoned manager scratching their head, wondering what the health inspector would say.

Let's clear up some of the most common questions that pop up in pizzerias, especially around those constantly-in-use pizza prep tables.

How Should I Temp Different Pizza Toppings?

Good question. Taking the temperature of a pan of sliced pepperoni is a whole different ballgame than checking shredded mozzarella.

For solid items like pepperoni, cooked sausage, or sliced ham, it's pretty straightforward. Just stick the thermometer probe into the thickest part of the meat, making sure the tip gets right to the center.

For loose items like shredded cheese, diced onions, or chopped peppers, you’re looking for an average reading. Plunge the probe deep into the center of the food mass, well away from the sides of the pan. The key is to avoid letting the thermometer touch the cold metal of the pan itself—that can throw off your reading and give you a false sense of security.

What’s the Protocol for a Missed Log Entry?

It happens. The lunch rush hits hard and a team member completely forgets to fill out a line on the log. The most important thing here is to be honest and act fast.

- Never, ever backdate or guess. Don't let staff try to remember what the pizza prep table's temperature might have been hours ago. That falsifies a legal document and makes the entire log useless.

- Log it right now. The moment you notice the missed entry, take the temperature immediately.

- Make a note of it. In the "Corrective Actions" column, the employee should jot down something simple and honest, like, "Missed 12 PM log. Temp checked at 1:15 PM, reading 39°F."

This shows a health inspector that you have a transparent process for human error, which looks a lot better than trying to cover things up.

The golden rule of food safety documentation is integrity. An honest record with a noted correction is always better than a "perfect" log that’s been fudged. Transparency is everything.

How Long Do I Have to Keep My Temperature Logs?

Record retention rules can feel a bit murky because they sometimes vary by local health departments. A good rule of thumb that will keep you safe in most places is to hold onto your completed temperature logs for at least 90 days.

That said, some jurisdictions might require you to keep them for six months or even a full year. Your best bet is to check directly with your local health authority to confirm their specific requirement. This is one area where digital logging systems really shine, since they can store your records in the cloud pretty much forever.

How Often Do My Thermometers Need to Be Calibrated?

Think of your thermometers like any other critical piece of kitchen equipment—they need regular tune-ups to stay accurate. Over time, they can drift and give you bad readings.

They should be professionally calibrated at least once a year. On top of that, your team should be doing a quick-and-easy ice-bath calibration weekly, if not daily, just to make sure they’re on point. And if a thermometer ever gets dropped on the pizzeria floor? It needs to be recalibrated immediately before it goes back into service.

At Pizza Prep Table, we know that reliable equipment is the bedrock of food safety. Our entire selection of NSF-compliant refrigerated pizza prep tables is built to hold consistent, safe temperatures, even when you're slammed during the dinner rush. Check out our durable and efficient models to find the perfect workhorse for your pizzeria.