A Pizzeria's Guide to Food Warming Tables

Share

In a busy pizzeria, every second and every degree counts. A small drop in temperature can be the difference between a perfect pizza and a meal that disappoints a customer. That’s where food warming tables come in—they're the unsung heroes of your pizza prep table, fighting off soggy crusts, cold toppings, and the chaos of a dinner rush by holding everything at just the right, food-safe temperature.

Why Consistent Temperature Is a Pizzeria's Secret Ingredient

Think about the life of a pizza in your kitchen. It goes from the pizza prep table to a blazing hot oven, and finally, into a box waiting for pickup. Temperature management is the thread that ties every one of those steps together. If that thread breaks, the whole process falls apart, hitting both your food quality and your kitchen's speed.

A food warming table is the critical bridge in that process. It’s not just about keeping food from getting cold; it's about holding it in its ideal state. For instance, marinara sauce kept at a steady 165°F flows perfectly every time, while cooked sausage and pepperoni stay juicy and ready to go without cooling down. This is the kind of consistency that separates a good pizzeria from a great one.

The Role of Warming Tables in Your Pizza Prep Workflow

When you integrate them properly, food warming tables do a lot more than just hold food. They turn clunky, disconnected steps into a smooth, efficient dance, letting your pizza makers work faster and smarter.

- Ingredient Readiness: Pre-cooked toppings like grilled chicken or sautéed mushrooms stay at the perfect temp on your pizza prep table, turning assembly into one fluid motion.

- Quality Preservation: Finished pies waiting for pickup on a heated shelf keep that "just out of the oven" heat and crispness. Your last customer of the night gets the same amazing pizza as your first.

- Reduced Food Waste: By holding ingredients safely above the temperature danger zone, you minimize spoilage and get more out of every ingredient you buy for your pizzas.

A well-placed food warming table transforms your pizza prep line from a series of disjointed tasks into a synchronized, high-speed production system. It’s the key to handling the dinner rush without sacrificing the quality that defines your brand.

At the end of the day, this isn't just about taste—it's about safety. Getting a handle on the principles of temperature control for food safety is non-negotiable for any successful pizzeria. It’s how you guarantee every slice is as safe as it is delicious, protecting both your customers and your reputation.

Decoding the Different Types of Warming Tables for Pizzerias

Navigating the world of commercial kitchen equipment can feel a little overwhelming, but picking the right food warming tables for your pizzeria comes down to one simple idea: match the tool to the task. Just like you wouldn't use a dough sheeter to slice pepperoni, different warmers are built for specific jobs in your pizza-making workflow. Getting these distinctions right is the first step toward building a faster, more efficient pizza prep line.

Not all pizza ingredients can be held with the same kind of heat. Some need a gentle, moist environment to stay perfect, while others require dry heat to keep their texture just right. This is where the different types of warming tables become a huge advantage for your pizzeria's quality control.

Steam Tables for Moist Pizza Toppings

Picture your signature marinara sauce—rich, perfectly seasoned, and ready to go. If you hold it under a dry heat lamp, it will quickly reduce, thicken, and maybe even scorch. That completely changes the flavor you worked so hard to create. This is the exact problem that steam tables were born to solve for pizzerias.

A steam table, sometimes called a wet-heat or bain-marie style warmer, uses a hot water bath to create a gentle, humid environment for the food pans sitting above it. This moist heat is the perfect solution for pizza toppings like:

- Sauces: Keeps marinara, alfredo, or pesto at a consistent, easily spreadable temperature without evaporating or forming a skin on top.

- Sautéed Vegetables: Stops mushrooms, onions, and bell peppers from drying out and turning rubbery.

- Cooked Meats in Sauce: Perfect for holding meatballs or sliced Italian sausage, keeping them juicy and tender.

By wrapping the food in a cushion of warm, moist air, a steam table makes sure your wet ingredients keep their intended texture and flavor for hours. Think of it as the ultimate guardian for the heart and soul of your pizza toppings.

Drop-In Warmers for Custom Pizza Prep Tables

While steam tables are the champs for sauces, a lot of your pizza toppings need to be kept hot and dry. This is where drop-in warmers offer a slick, integrated solution for your pizza prep table. These units are designed to be installed right into a countertop, creating a seamless, custom-built pizza prep station.

Drop-in units typically use dry heating elements, which makes them perfect for holding items that need to stay crisp or avoid getting soggy. They deliver direct, consistent heat to food pans filled with pre-cooked toppings like ground beef, sausage crumbles, or grilled chicken. This setup puts everything your pizza makers need right within arm's reach, which dramatically speeds up assembly times during a busy service.

A well-designed pizza prep station might even feature a drop-in warmer right next to the refrigerated wells, creating a complete hot-and-cold topping station that’s a model of efficiency.

Heated Shelves for Finished Pizzas

The final, and maybe most critical, stage for a finished pizza is the handoff to the customer or delivery driver. A pizza that sits for even a few minutes can lose that "just-out-of-the-oven" magic. Heated shelves and pass-through windows are your essential final checkpoint, ensuring every single pie stays piping hot until the moment it leaves your pizzeria.

These units use radiant, dry heat to keep both the pizza and its box warm without making the crust soggy—think of it as a temperature-controlled landing zone. By placing finished pizzas on a heated shelf in a pass-through area, you create an organized system for drivers and customers to grab their orders. This simple workflow prevents chaos at the counter and guarantees that the last bite of a delivered pizza is just as warm and satisfying as the first. This is a huge deal, as studies show that food temperature is a top factor in customer satisfaction with delivered meals.

Picking the right table for each stage of your pizzeria's workflow is key to efficiency and quality. Here’s a quick breakdown to help you visualize where each type fits best.

Choosing the Right Warming Table for Your Pizzeria

| Table Type | Primary Pizzeria Use | Heating Method | Best For Pizza Toppings |

|---|---|---|---|

| Steam Table | Holding sauces and wet toppings on the pizza prep line | Wet (Hot Water Bath) | Marinara, alfredo, sautéed vegetables, meatballs in sauce. Anything that needs to stay moist. |

| Drop-In Warmer | Holding dry, pre-cooked toppings on the pizza prep table | Dry (Heating Elements) | Ground beef, sausage crumbles, grilled chicken. Keeps toppings hot without making them soggy. |

| Heated Shelf | Staging finished pizzas for pickup or delivery | Dry (Radiant Heat) | Keeping boxed pizzas hot and crisp until they leave the store, ensuring customer satisfaction. |

Ultimately, the goal is to create a smooth path for your pizza ingredients, from prep to the final product. By using a combination of these warming tables, you ensure every component of your pizza is held at its ideal temperature, protecting both flavor and food safety.

Key Features and Specs for Your Pizza Prep Table

Once you've figured out which types of warming tables you need for your pizzeria, the real work begins. Now you have to dig into the nitty-gritty specs that separate a reliable workhorse from a piece of equipment that's going to cause major headaches on a chaotic Friday night.

These technical details define how a unit performs when you’re slammed. Paying attention now ensures your pizza prep line is built for speed, durability, and most importantly, precision. Think of it like picking an engine for a delivery car. Sure, several options might get the pizza from A to B, but only the right one has the power, reliability, and efficiency to make your operation profitable. The same logic applies here.

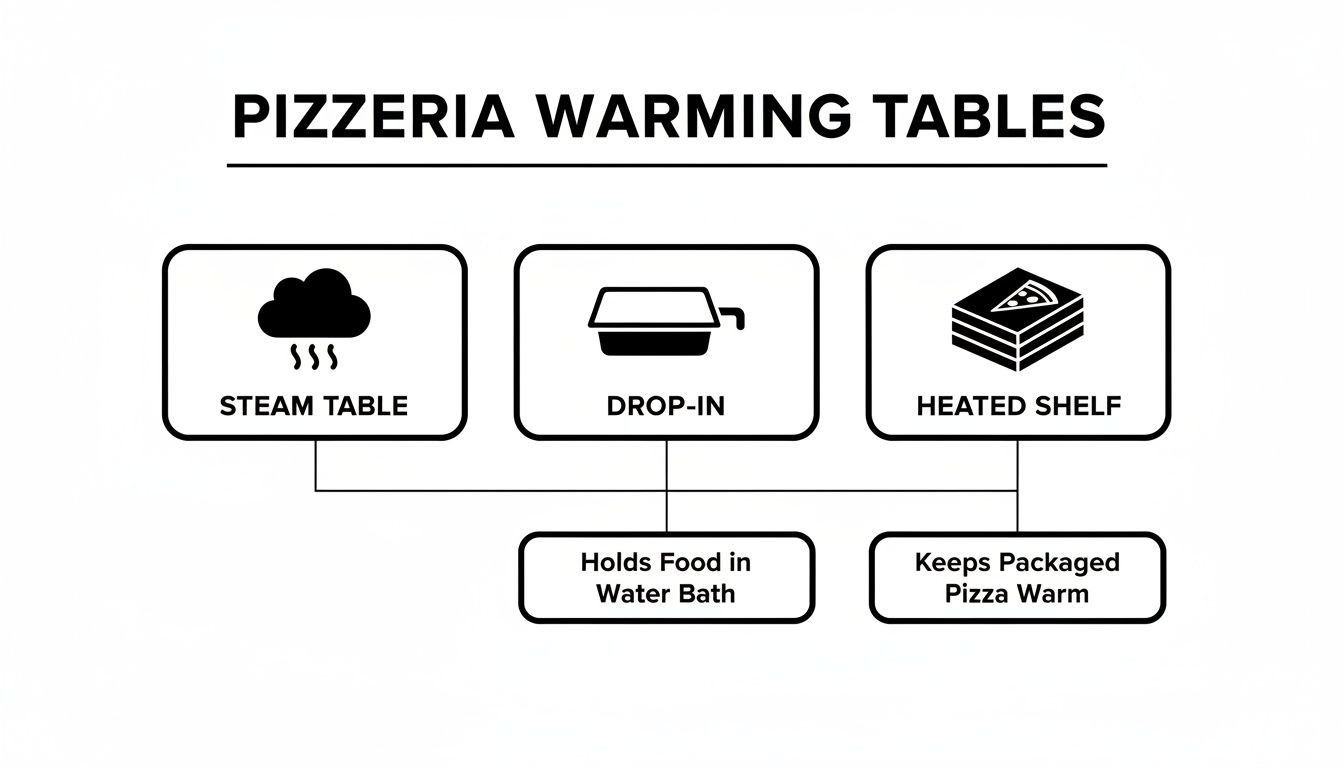

This diagram breaks down where different types of warming tables fit into a typical pizzeria workflow, showing how each has a specific job to do.

As you can see, specialized units like steam tables, drop-ins, and heated shelves each play a unique role in the pizza-making process, from holding moist sauce ingredients to keeping finished pies hot and ready for pickup.

Digital Versus Analog Temperature Controls

One of the first decisions you'll face is choosing between digital and analog temperature controls, and it's a more critical choice than you might think. Analog controls use a simple dial—think old-school oven—with vague settings like low, medium, and high. While they're dead simple to use, they just don't offer the precision needed for sensitive pizza ingredients.

Digital controls, on the other hand, let you dial in an exact temperature. This level of accuracy is non-negotiable for items like cheese sauce or a delicate alfredo that can scorch or break if the temperature swings even a few degrees. For a pizzeria, digital controls are a must-have to keep your product quality consistent, pizza after pizza.

Imagine holding a creamy alfredo sauce for a specialty pizza. With a digital thermostat, you can set it to a precise 160°F to keep it perfect. An analog dial's "medium" setting could swing wildly between 150°F and 175°F, ruining an entire batch of sauce and torching your food cost.

Stainless Steel Grades: The Battle Against Pizza Sauce Acidity

Pizza ingredients, especially that classic tomato sauce, are highly acidic. Over time, this acidity will eat away at lower-quality metals, causing corrosion and pitting that create sanitation nightmares and kill your equipment's lifespan. This is where the grade of stainless steel becomes incredibly important for your pizza prep table.

Most commercial kitchen equipment is built from one of two grades:

- 430 Stainless Steel: This is the more budget-friendly, magnetic grade you'll often find on the exterior body and legs. It holds up decently but is far more likely to corrode when constantly exposed to acids and salts from pizza toppings.

- 304 Stainless Steel: This is the real deal, often called "food-grade" stainless steel. It contains more chromium and nickel, making it highly resistant to corrosion and rust. It's the only choice for any surface that touches food, especially acidic pizza sauces.

For any warming table on your pizza line, make it a rule to get 304-grade stainless steel for all food contact zones. It might cost a bit more upfront, but the long-term durability and safety are well worth the investment.

Translating Power Ratings for Your Pizzeria

Finally, you need to understand power ratings to make sure a new unit will actually work in your pizzeria. Power for these tables is measured in British Thermal Units (BTUs) for gas models and wattage for electric ones.

A small electric drop-in warmer for a single pan might only need 500-800 watts, plugging right into a standard wall outlet. But a big, multi-well gas steam table could demand 30,000 BTUs or more, requiring a dedicated professional gas line installation.

Before you click "buy," double-check your kitchen's electrical panel and gas capacity. Matching the equipment's power needs to what your shop can provide ensures a smooth, safe installation and prevents frustrating issues like slow preheating or tripped breakers during your busiest hours.

Designing Your Pizzeria Workflow Around Warming Tables

Buying the right food warming tables is just the first step. Unlocking what they can really do for your pizzeria comes down to one thing: where you put them. A top-of-the-line warmer in the wrong spot can create bottlenecks, slow down your team, and add a layer of chaos to an already busy shift.

Smart kitchen design transforms these tables from simple appliances into the very heart of your pizza prep line, dictating the speed and rhythm of every order. The goal is to create a seamless flow that cuts out wasted steps and pushes out more pizzas, faster. This isn't just about convenience; it's about building a system where every movement has a purpose, especially when the dinner rush hits.

Creating the Pizzeria Work Triangle

In home kitchens, you always hear about the “kitchen triangle” connecting the sink, stove, and fridge. Pizzerias have their own version, and it's even more critical: the triangle that links the pizza prep table, the oven, and the pass-through window. Every single step your staff takes between these three points adds precious seconds to ticket times.

Smart placement of warming tables is the key to shrinking those paths.

- Prep Station Integration: Your steam tables and drop-in warmers holding sauces and toppings need to be built directly into the main pizza prep table. This lets your pizza makers assemble pies without ever having to walk away to grab hot ingredients.

- Oven Adjacency: The pizza prep table itself has to be as close to the oven as possible. You want a direct, one-way path from assembly to baking to eliminate any cross-traffic or confusion.

- Pass-Through Placement: That heated shelf for finished pizzas? It belongs right next to the oven's exit. As soon as a pizza is boxed, it goes straight onto the shelf, ready for pickup with zero extra handling.

This layout creates a true assembly line where the pizza always moves forward, never backward. A well-designed workflow allows a small team to pump out a shocking volume of orders with less stress and fewer mistakes.

Strategic equipment placement isn't a luxury; it's an operational necessity. By minimizing staff movement by just a few steps per pizza, a pizzeria can save dozens of wasted hours per month, directly boosting productivity and profitability.

Applying Ergonomics and Safety on the Pizza Line

Beyond just shortening distances, ergonomic design plays a huge role in your team's performance and well-being. A poorly designed workspace leads to fatigue, and fatigue leads to mistakes and slower service. Your layout should put comfort and safety first.

Think about the height of your food warming tables and pizza prep tables. Staff shouldn't have to constantly bend over or reach up high to get what they need. Surfaces should be at a natural working height, typically between 34 and 36 inches, to cut down on back strain over a long shift. You can explore a variety of layout strategies in our guide to commercial kitchen layout design.

Also, don't forget about ventilation, especially for gas-powered steam tables that kick out a lot of heat and moisture. Good airflow keeps the kitchen comfortable and stops grease and steam from building up.

As the foodservice industry keeps growing—with the food warmer market projected to hit USD 4.1 billion by 2032—an efficient and safe pizzeria design becomes a massive competitive advantage. This focus on ergonomics doesn't just keep your team happy; it keeps them working at peak efficiency, which is what every successful pizzeria needs.

Mastering Food Safety and NSF Compliance for Pizzerias

Beyond churning out delicious pizzas, the most important job your equipment has is keeping customers safe. A food warming table isn't just a piece of hardware for convenience; it's your frontline defense against foodborne illness and a key player in passing health inspections with flying colors. For any pizzeria, mastering temperature control is non-negotiable.

This is where understanding certifications really matters. When you see that NSF (National Sanitation Foundation) mark on a warming table or pizza prep table, it's more than just a sticker. It's a guarantee that the equipment has been put through the wringer—rigorously tested and proven to meet strict public health and safety standards. An NSF-certified unit is built with food-safe materials, designed to be cleaned easily, and performs reliably under the stress of a commercial kitchen.

Navigating the Temperature Danger Zone with Pizza Toppings

The absolute core principle of food safety is steering clear of the "Temperature Danger Zone." This is the range between 40°F and 140°F (4°C and 60°C) where bacteria can multiply at an alarming rate. Your hot pizza toppings—from cooked sausage to marinara sauce—have to be held at temperatures above this threshold to be safe to serve.

NSF-certified food warming tables are engineered for this exact purpose. Their thermostats and heating elements are designed to consistently hold temperatures well above 140°F, ensuring your pizza ingredients stay out of the danger zone for the entire service. It's one of the first things a health inspector will check.

Think of NSF certification as a built-in safety feature. It's the confirmation that your equipment can hold food at a consistent, safe temperature, creating a fortress against harmful bacterial growth and giving you some much-needed peace of mind for your pizzeria.

Practical Cleaning for Pizzeria Compliance

Maintaining that safety standard day in and day out requires a strict cleaning routine. Different types of warming tables have their own quirks, and following the right steps is crucial for preventing cross-contamination and getting the most life out of your equipment. For a broader look, you can explore detailed food safety guidelines for restaurants that cover all sorts of kitchen practices.

Here are the essential cleaning steps for the units you'll typically find in pizzerias:

- Daily Cleaning (All Units): At the end of every shift, turn off and unplug the unit. Once it's cool, pull out all the food pans and run them through your three-compartment sink. Wipe down every interior and exterior surface with a food-safe detergent and a soft cloth, then sanitize and let it all air dry.

- Weekly Steam Table Maintenance: If you're using a wet-heat steam table for your sauces, it's critical to drain the water wells and clean them thoroughly. This prevents mineral buildup (scaling) from hard water, which can kill the efficiency of your heating elements. Use a descaling solution when you see it start to build up.

- Caring for Stainless Steel: Whatever you do, never use steel wool or harsh abrasive cleaners on stainless steel. They create tiny scratches that become perfect hiding spots for bacteria. Always wipe in the direction of the steel's grain to keep its protective layer intact.

While NSF is all about the public health and safety of food equipment, understanding broader workplace safety standards also helps create a safer, more compliant pizzeria. By pairing certified equipment with disciplined daily habits, you ensure every pizza that leaves your kitchen is not only delicious but completely safe.

Maintenance Routines and Troubleshooting Common Issues

Your food warming tables are the unsung heroes of your pizzeria, quietly working behind the scenes to keep ingredients perfect and finished pies ready for pickup. Just like your prized pizza oven, they need a little bit of consistent care to perform day in and day out. Thinking about maintenance isn't a chore—it's the smartest way to dodge costly downtime, guarantee food safety, and get the most life out of your gear.

A few minutes of care at the end of a shift can be the difference between a smooth service and a complete disaster during a Friday night pizza rush. This isn't about becoming a repair technician; it's about taking ownership of your equipment so your kitchen runs like a well-oiled machine.

Your Preventative Maintenance Checklist

The best way to tackle maintenance is to break it down into simple, manageable tasks. A consistent schedule for daily, weekly, and monthly checks makes it easy to delegate and ensures nothing gets missed on your pizza prep line.

- Daily Tasks (5-10 Minutes): At the end of every single shift, wipe down all interior and exterior surfaces with a food-safe cleaner. If you're using steam tables for sauces, drain the water, give the wells a good cleaning, and let them air dry completely. This is critical for preventing nasty mineral buildup and bacterial growth.

- Weekly Tasks (15-20 Minutes): Once a week, take a closer look. Inspect your power cords for any signs of fraying or damage—a common issue in busy pizzerias. Grab an external thermometer and double-check the accuracy of the unit's thermostat. You need to be sure it's holding food well above that 140°F safety line.

- Monthly Tasks (20-30 Minutes): This is your deeper dive. Check the gaskets on any heated cabinet doors for cracks or wear. A bad seal is a huge energy waster and makes it impossible to hold a consistent temperature. You should also peek at the heating elements to make sure they're all glowing evenly.

Adopting this kind of forward-thinking approach, similar to these proactive maintenance strategies for commercial equipment, helps you catch small issues before they snowball into big, expensive problems that can shut down your pizza line.

Troubleshooting Common Warming Table Problems

Even with the best maintenance routine, things can still go wrong. Knowing how to diagnose a few common issues can save you from an expensive service call for what might be a simple fix.

Key Takeaway: Before you even think about calling a technician, always check two things. First, is the unit plugged in securely to an outlet that you know is working? Second, is the thermostat actually turned on and set to the right temperature? You'd be amazed how often these simple oversights are the "problem."

If you've covered those bases and still have an issue, here are a couple of common scenarios you might run into at your pizzeria.

Problem 1: The Table Won’t Get Hot

If the unit has power but just isn't heating up, the problem is usually the heating element or the thermostat. The first thing to do is check your circuit breaker to see if it's been tripped. If the breaker is fine, the issue is likely internal. This is when it's time to call a qualified technician to safely check and replace any faulty parts.

Problem 2: Uneven Heating Across the Table

This is a classic complaint, especially with multi-well steam tables holding different pizza toppings. Sometimes, the cause is as simple as an overloaded unit where the pans are jammed in too tightly, blocking airflow. Other times, it could point to a failing heating element in one section or a heavy mineral buildup that's insulating an element from the water. Your first move should be to descale the wells. If that doesn’t solve it, you'll need a pro.

Your Questions, Answered

When you're looking at a piece of equipment as vital as a food warming table for your pizza prep line, you’re bound to have some questions. Let's tackle the most common ones we hear from pizzeria owners to help you make the right call for your kitchen.

Can I Use a Food Warming Table to Reheat Cold Food?

That's a hard no, and it's one of the most critical food safety rules you can follow in a pizzeria. A food warming table is designed for one job and one job only: to hold already hot food at a safe temperature, which is 140°F (60°C) or higher.

These units simply don't have the power to blast cold food through the temperature danger zone fast enough. Trying to do so is like giving bacteria an open invitation to a party. Always cook or reheat your pizza toppings in an oven, microwave, or on the stove first. Once it hits the right internal temp, then you can move it to the warming table on your pizza prep line to keep it perfect for service.

What Is the Difference Between a Wet and Dry Warming Table?

The real difference is how they heat your food, and this choice has a huge impact on the texture and quality of your pizzeria ingredients.

- A "wet" table is basically a steam table. It uses a hot water bath to generate a gentle, moist heat. This is perfect for anything that tends to dry out, like your house-made marinara sauce, sautéed peppers and onions, or meatballs for a meatball pizza.

- A "dry" table uses heating elements that give off direct, radiant heat. This is your go-to for keeping crispy items—like pre-cooked bacon or sausage crumbles—from turning into a soggy mess. For holding finished, boxed pizzas, a dry heated shelf is always the way to go.

Think of it like this: a wet table is a sauna, keeping things moist, while a dry table is like a desert sun, keeping things crisp. You need to match the pizza topping to the right environment.

Should I Choose a Gas or an Electric Warming Table?

This really boils down to your pizzeria's utility setup and what you need the table to do. Electric tables are the champions of precise temperature control. With their digital thermostats, they're perfect for holding delicate ingredients on a pizza prep line where a few degrees can make all the difference. Plus, they're usually much easier to install.

Gas tables, which you'll often see in high-volume steam table setups, can heat up a bit faster and might have lower running costs depending on your local gas prices. But for most pizzerias, electric units provide the perfect balance of control and convenience, whether you're holding toppings on the prep table or staging finished pies.

How Often Should I Clean My Food Warming Table?

You need a strict cleaning schedule—it's non-negotiable for food safety, keeping your equipment alive longer, and acing your health inspections. A basic cleaning needs to happen every single day. After the unit has cooled down, wipe down every surface and give all the removable food pans and lids a thorough washing.

Once a week, it's time for a deeper clean. This is when you should pull out an external thermometer to double-check that your thermostat is still accurate. If you have a wet table for sauces and live in an area with hard water, this is also your chance to descale the steam elements to prevent buildup.

Ready to build a more efficient and reliable pizza prep line? Pizza Prep Table offers a curated selection of NSF-compliant food warming tables and pizza prep stations designed for the demands of a busy pizzeria. Explore our equipment and find the perfect fit for your kitchen at https://pizzapreptable.com.