From Hearth to Heart: Choosing Your Commercial Wood Fired Pizza Oven

Share

The Sizzle of Authenticity in Commercial Wood Fired Cooking

A commercial wood fired pizza oven delivers authentic flavors and high-heat cooking that sets your pizzeria apart. Here's what you need to know:

Key Benefits:

- Temperature: Reaches 900°F+ for 90-second cook times.

- Capacity: Cook 7 pizzas at once, 70-200 pizzas per hour.

- Efficiency: Uses up to 6x less fuel than traditional ceramic ovens.

- Heat-up time: Modern models ready in just 45 minutes.

Top Models to Consider:

- Forno Bravo Modena2G: High-volume production (200+ pizzas/hour).

- Marra Forni Revolving: Labor-saving automation.

- Fontana Forni Prometeo: Fast heat-up with stainless steel construction.

The crackling wood and dancing flames create a magical atmosphere. As one pizzeria owner found, "After testing multiple ovens from many other brands and then trying Marra Forni's ovens, THERE WAS NO COMPARISON."

The authentic smoky flavor and leopard-spotted crusts from wood-fired cooking have made these ovens the heart of successful pizzerias. Choosing the right one requires understanding capacity, installation, and operational costs.

My experience in the foodservice industry has shown that the right commercial wood fired pizza oven can transform your kitchen's efficiency and your customers' dining experience. Let me guide you through making the perfect choice for your business.

Why a Wood Fired Oven is the Heart of a Great Pizzeria

A commercial wood fired pizza oven is more than equipment—it's the heart of an authentic pizzeria experience. The sight of the glowing dome and the sound of crackling wood signal something special to customers, creating theater and tradition.

The Unmistakable Flavor and Performance Benefits

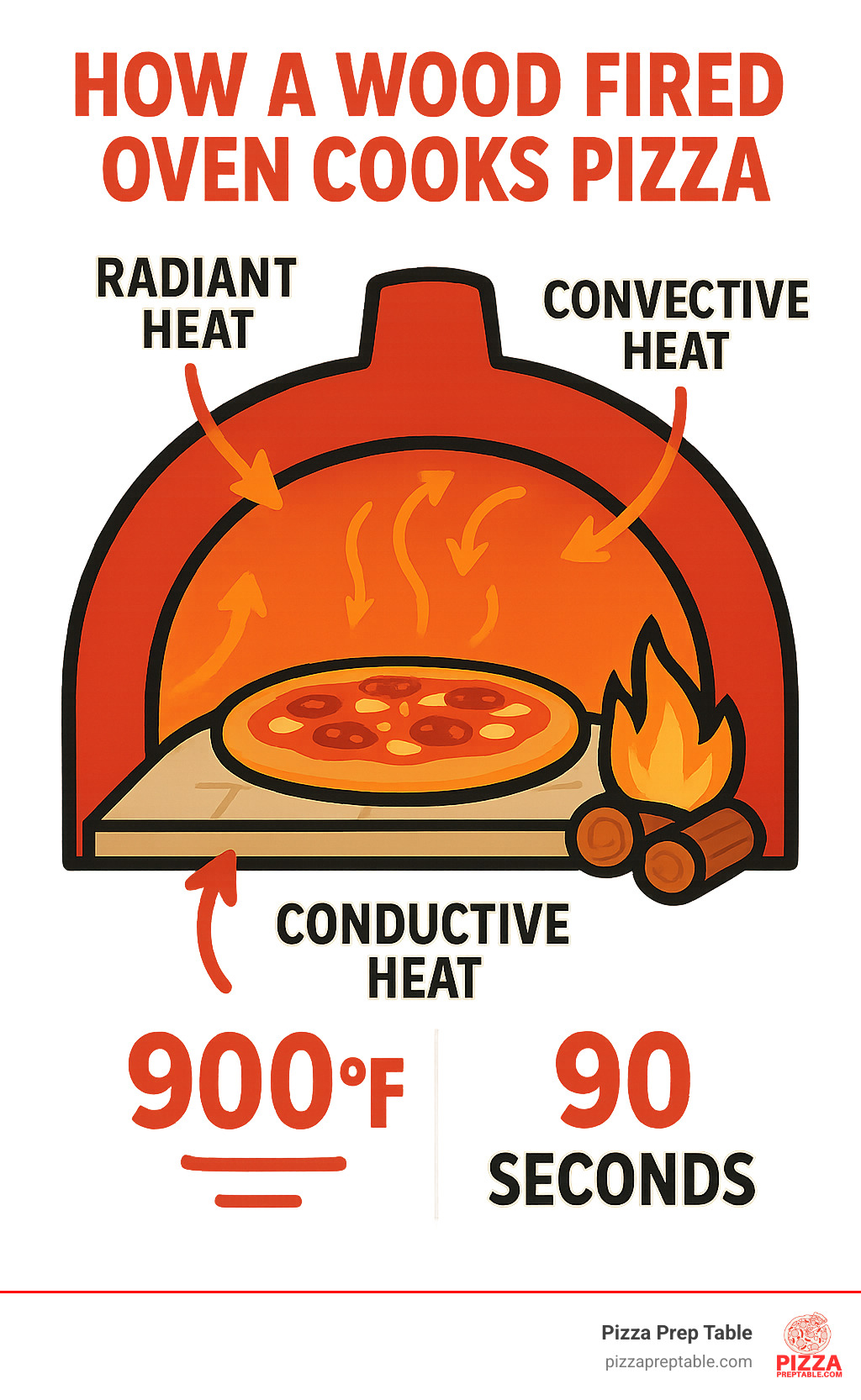

The magic lies in the extreme temperatures. A commercial wood fired pizza oven reaches a scorching 900°F or higher, cooking pizzas in just 60 to 90 seconds. This speed is possible due to a combination of heat types: radiant heat from the dome cooks toppings, convective heat from hot air crisps the crust, and conductive heat from the stone floor creates the coveted leopard spots.

This rapid cooking locks in moisture, resulting in a crust that's crispy outside and tender inside. The wood smoke infuses every bite with an authentic flavor that can't be replicated, an authenticity customers taste immediately.

These ovens are also productivity powerhouses, with many models handling seven pizzas at once and producing 70 to 100 pizzas per hour. Their menu versatility is another key benefit; beyond pizza, you can roast vegetables, cook meats, and bake artisan bread, making your oven a culinary workhorse.

For more inspiration on classic styles, check out our guide on New York Style Pizza.

Commercial Wood Fired Pizza Oven vs. Gas and Electric

Choosing a fuel type can be overwhelming. Understanding the key differences helps you make the right call for your business.

| Feature | Wood-Fired | Gas | Electric |

|---|---|---|---|

| Flavor | Unmistakable smoky, authentic flavor with unique char | Consistent, clean flavor without smoke infusion | Clean, consistent flavor without smoke infusion |

| Heat-Up Time | Modern ovens: 45 minutes; Traditional: 2-3 hours | Generally 30-60 minutes | Quickest at 20-30 minutes |

| Temperature | Highest at 900-1000°F with excellent heat retention | Typically 500-800°F with precise control | Precise control up to 700°F with stable heat |

| Cost | Higher initial investment; ongoing wood costs | Moderate investment; cost-effective gas operation | Moderate investment; higher electricity costs for high volume |

| Skill Level | Requires skilled fire management and temperature control | Easier operation with less skill needed | Easiest with push-button simplicity |

Wood-fired ovens excel in marketing appeal and creating an authentic experience. The fire itself becomes a draw for customers.

Gas ovens offer consistency and ease of use, ideal for operations needing reliable results with less specialized training.

Electric ovens provide precision control and are available in ventless options, perfect for locations with ventilation challenges.

While gas and electric ovens offer convenience, they cannot replicate the smoky depth and unique texture of wood-fired cooking. A commercial wood fired pizza oven creates a memorable sensory experience.

Want to dive deeper into the technical differences? Check out this discussion on What is the difference between a wood-fired pizza oven and a gas pizza oven?

Your Ultimate Buyer's Guide: Finding the Perfect Fit

Choosing the right commercial wood fired pizza oven requires matching your ambitions to your space and operational needs. The best choice comes down to three critical factors: throughput, installation, and construction.

Size, Capacity, and Throughput

Start by asking: how many pizzas do you need to serve during peak hours? Consider your busiest nights, catering orders, and unexpected rushes.

Pizza capacity varies significantly. A compact unit might handle seven 10-inch pizzas simultaneously, while larger models can hold more.

Hourly throughput is a critical metric. Many commercial wood fired pizza ovens produce 70-100 pizzas per hour, but high-volume models like Marra Forni's Rotator can reach 250 pizzas per hour, and Forno Bravo's Modena2G exceeds 200 pizzas per hour. This capacity can be the difference between success and losing customers.

Cooking floor dimensions determine how many pizzas you can bake at once. More surface area means faster service. While single-deck ovens are common, some designs offer stacking or higher-capacity configurations.

Match your oven size to your business volume. A smaller unit may suit a neighborhood café, but a busy pizzeria needs the horsepower to keep up. It's better to have extra capacity than to be overwhelmed.

For a deeper dive into your options, check out our guide on different Commercial Pizza Ovens.

Installation, Venting, and Space Requirements

Proper installation is crucial for safety and performance. Here's what to consider:

Assembled vs. Modular Kits: Fully assembled units, like some from Forno Bravo, arrive ready to cook and can be installed quickly with a forklift. Modular kits fit through standard doorways, offering flexibility when access is limited.

Weight and Access: These ovens are heavy. The Napoli120 weighs over 5,200 pounds, so your floor must support it. Most assembled units require forklift access for placement.

Venting: Proper venting is non-negotiable. Every commercial wood fired pizza oven requires a UL-listed, commercial-grade chimney system. Options include a Type 1 hood or a direct-connect grease duct. Both must use UL103HT rated chimney pipe and cap to handle high temperatures safely.

Certifications: Look for ovens ETL listed to UL, ULC, NSF, and ANSI standards. These certifications ensure the oven meets strict safety and sanitation requirements. Forno Bravo and Marra Forni ovens carry these certifications, with Marra Forni also having CE certification for international markets.

Placement: Many modern ovens, like the Napoli120 and Roma110, are UL certified for both indoor and outdoor installation, offering design flexibility.

Planning your space around your new oven takes some creativity. For inspiration on making it work beautifully, explore our Creative Pizza Shop Design Ideas.

Materials, Insulation, and Efficiency

An oven's construction dictates its heat-up time, fuel consumption, and longevity. Understanding the materials is key to choosing a durable, efficient oven.

Refractory Materials: The core of a great wood-fired oven is made of refractory materials (bricks or pre-cast cement) that withstand extreme heat. Marra Forni uses its proprietary "MarraStone" from volcanic material for superior heat retention, while Forno Bravo uses thick, high-grade refractory cores for high thermal mass.

Firebrick vs. Stainless Steel: Traditional firebrick offers excellent thermal mass. In contrast, innovative brands like Fontana Forni use 310 S stainless steel, which is resistant to corrosion up to 2,100°F. Stainless steel ovens heat up faster, making them ideal for mobile operations.

Insulation: Thick insulation is crucial for fuel efficiency. Fontana Forni uses 12 centimeters of insulation, and Forno Bravo uses 4-6 inches of premium ceramic fiber insulation. This keeps the oven hot longer, saving on wood costs.

Heat Retention and Efficiency: High thermal mass from a thick dome and floor maintains consistent temperatures during busy service. Modern ovens are highly efficient; Fontana Forni claims their models use up to 6x less wood than traditional ceramic ovens, leading to significant long-term savings.

Heat-Up Time: Modern designs have drastically reduced preheating times. Many commercial models are ready in just 45 minutes, compared to the 2-3 hours required for older ceramic ovens.

Investing in a well-built, properly insulated oven means lower fuel costs, faster startup times, and consistent performance that keeps your kitchen running smoothly. If you're ready to make this investment, we offer flexible financing options for your oven purchase to help you get cooking without the financial stress.

Top Commercial Wood Fired Pizza Ovens on the Market

After years in the restaurant supply industry, I've seen how the right oven can transform a business. Let me walk you through the top brands that consistently deliver exceptional performance and reliability.

Forno Bravo: The American-Made Italian Tradition

Forno Bravo manufactures its commercial wood fired pizza ovens in California, blending Italian design with American craftsmanship.

They offer a wide range of options:

- The Modena2G Series is a high-volume beast, producing over 200 pizzas per hour with its thick, heat-storing dome.

- The Professionale Series provides quality craftsmanship for smaller operations with faster heat-up times.

- The Napoli Series is a popular centerpiece oven with a center dome vent for even temperatures, ideal for authentic VPN-style pizza.

- The Roma Series is versatile, transportable, and customizable with hand-tiled exteriors.

Forno Bravo offers fully assembled ovens for quick installation and modular kits for custom builds or tight spaces. All their commercial ovens are ETL Certified to meet UL and CSA standards for the US and Canada. You can even Join the Forno Bravo Community Forum to connect with other owners and share experiences.

Marra Forni: Innovation Meets Craftsmanship

As the first VPN-approved manufacturer outside Italy, Marra Forni is known for its commitment to Neapolitan tradition and innovation.

Their revolving brick ovens are a game-changer for efficiency. The heated, rotating floor ensures consistent cooking and eliminates the need for manual pizza turning, saving significant labor costs. Combined with digital temperature controls, this system simplifies training and reduces waste.

For high-volume kitchens, their Pass-Thru models allow two chefs to work on opposite sides, maximizing throughput. Marra Forni uses its proprietary MarraStone refractory brick for superior heat retention, with ovens reaching up to 1000°F for authentic high-heat cooking.

Extensive customization options, including tiles, colors, and facades, allow you to design an oven that matches your restaurant's aesthetic.

For more insights on how these ovens perform in real-world conditions, check out Brick by Brick, Slice by Slice: Commercial Pizza Ovens Reviewed.

Fontana Forni: The Power of Stainless Steel

Fontana Forni offers a unique approach, building their cooking chambers with 2.5mm of 310 S Stainless Steel. This material withstands temperatures up to 2,100°F, offering incredible durability.

This innovative construction provides several advantages:

- Fast Heat-Up: Ovens are ready in just 45 minutes, a significant time-saver compared to the 2-3 hours for traditional ceramic models.

- Fuel Efficiency: Advanced construction and 12 centimeters of insulation mean these ovens use up to 6x less wood.

- Durability: The solid-weld dome construction is built to withstand demanding commercial use.

- Mobility: The lighter stainless steel construction makes them ideal for mobile catering operations.

The flagship Prometeo model is designed for high-performance restaurant use, reaching temperatures of 900°F for authentic pizza cooking.

Operating Your Commercial Wood Fired Pizza Oven Like a Pro

Getting the most from your commercial wood fired pizza oven means mastering fire management and proper maintenance. Once you find the rhythm, it becomes second nature.

Fueling the Fire: Choosing the Right Wood

The wood you choose is the foundation of your pizza's flavor.

Best Woods: Use seasoned hardwoods for a hot, steady, clean burn. Oak is the gold standard, with maple and ash being excellent alternatives. Fruitwoods like apple or cherry can add a subtle, sweet flavor.

Wood to Avoid: Never use green (unseasoned) wood, as it creates excessive smoke and burns poorly. Avoid softwoods like pine or cedar, which burn too fast and produce resin that taints food. Pressure-treated or construction lumber is dangerous and will ruin your oven and food.

Sourcing and Consumption: Fuel consumption depends on oven efficiency; modern models can use up to 6x less wood. Establish a relationship with a reliable local supplier for consistently dry, quality hardwood. The goal is a clean-burning fire that maintains steady heat with minimal smoke.

Essential Tools and Maintenance

The right tools and a solid maintenance routine are essential for smooth operation.

Essential Tools: Your toolkit should include long-handled pizza peels, a turning peel, a brass-bristle oven brush, an ash rake, and a shovel. An infrared thermometer is crucial for accurate temperature readings. Also have heat-resistant gloves, a poker, and a commercial fire extinguisher on hand.

Daily Maintenance: Remove spent ash from the firebox and cooking chamber after each service. Ash buildup can affect heat transfer and performance.

Deep Cleaning: When the oven is cool, scrape residue from the dome and floor. Regularly inspect and clean the chimney system to prevent dangerous creosote buildup.

Curing a New Oven: New ovens require curing—a process of small, gradual fires over several days to dry out moisture in the refractory materials. Always follow the manufacturer's curing instructions. Some brands, like Forno Bravo, offer pre-curing services.

Taking care of your oven isn't just about performance – it's protecting a significant investment that should serve your restaurant for many years. For a complete guide to all the supplies you'll need, check out our resource on Find the best pizza supplies here.

Frequently Asked Questions about Commercial Wood Fired Ovens

When investing in a commercial wood fired pizza oven, it's natural to have questions. Here are straightforward answers to the most common ones.

How long does it take to heat up a commercial wood fired pizza oven?

Heating time depends on the oven type. Modern, well-insulated ovens with stainless steel construction, like those from Fontana Forni, can heat up in just 45 minutes to an hour. Traditional, heavy-duty brick ovens need 2-3 hours to build thermal mass but retain heat for hours. Match your choice to your operational needs: fast heat-up for quick service, or high thermal mass for all-day cooking.

How many pizzas can a commercial wood fired oven cook per hour?

Throughput varies by model. Smaller commercial ovens can produce around 120 pizzas per hour. Mid-size ovens can handle over 150 pizzas per hour. High-volume workhorses like the Forno Bravo Modena2G or Marra Forni's Rotator can cook 200 to 250 pizzas per hour. Achieving these numbers requires an efficient prep workflow and skilled staff.

Do I need a special chimney for a commercial wood fired pizza oven?

Yes, proper ventilation is crucial for safety and performance. You must install a UL-listed, commercial-grade chimney system that meets local fire and health codes. Options include a Type 1 Hood or a direct-connect grease duct. The chimney components must be UL103HT rated to withstand the high temperatures (over 900°F). Always consult a qualified HVAC professional and your local building department early in the planning process to ensure compliance.

From Hearth to Your Customers' Hearts

Choosing the right commercial wood fired pizza oven is an investment in authenticity, flavor, and the soul of your pizzeria. The sight of dancing flames and the aroma of wood smoke create an unforgettable customer experience, culminating in a perfect, 90-second pizza.

We've covered the key decision factors: the unmistakable flavor, impressive throughput, and critical details of capacity, materials, and installation. Whether you prefer Forno Bravo's craftsmanship, Marra Forni's innovation, or Fontana Forni's efficiency, the right oven becomes a show-stopping centerpiece that tells a story of quality and tradition.

This investment will define your restaurant's identity, build customer loyalty, and generate powerful word-of-mouth marketing.

At Pizza Prep Table, we know a great pizzeria needs more than just an oven. You need fast prep tables, reliable refrigeration, and all the tools to create culinary magic. We are passionate about helping restaurants succeed, offering complete kitchen setups for businesses of all sizes, from Houston to Seattle.

Ready to bring the timeless tradition of wood-fired cooking to your restaurant? Explore our complete range of restaurant equipment and financing options today! Let's help you create something extraordinary—from the hearth straight to your customers' hearts.