Mastering the Slice: Pizza Cutter Techniques for Your Pizza Stone

Share

Why Proper Pizza Cutting Technique Matters for Your Stone

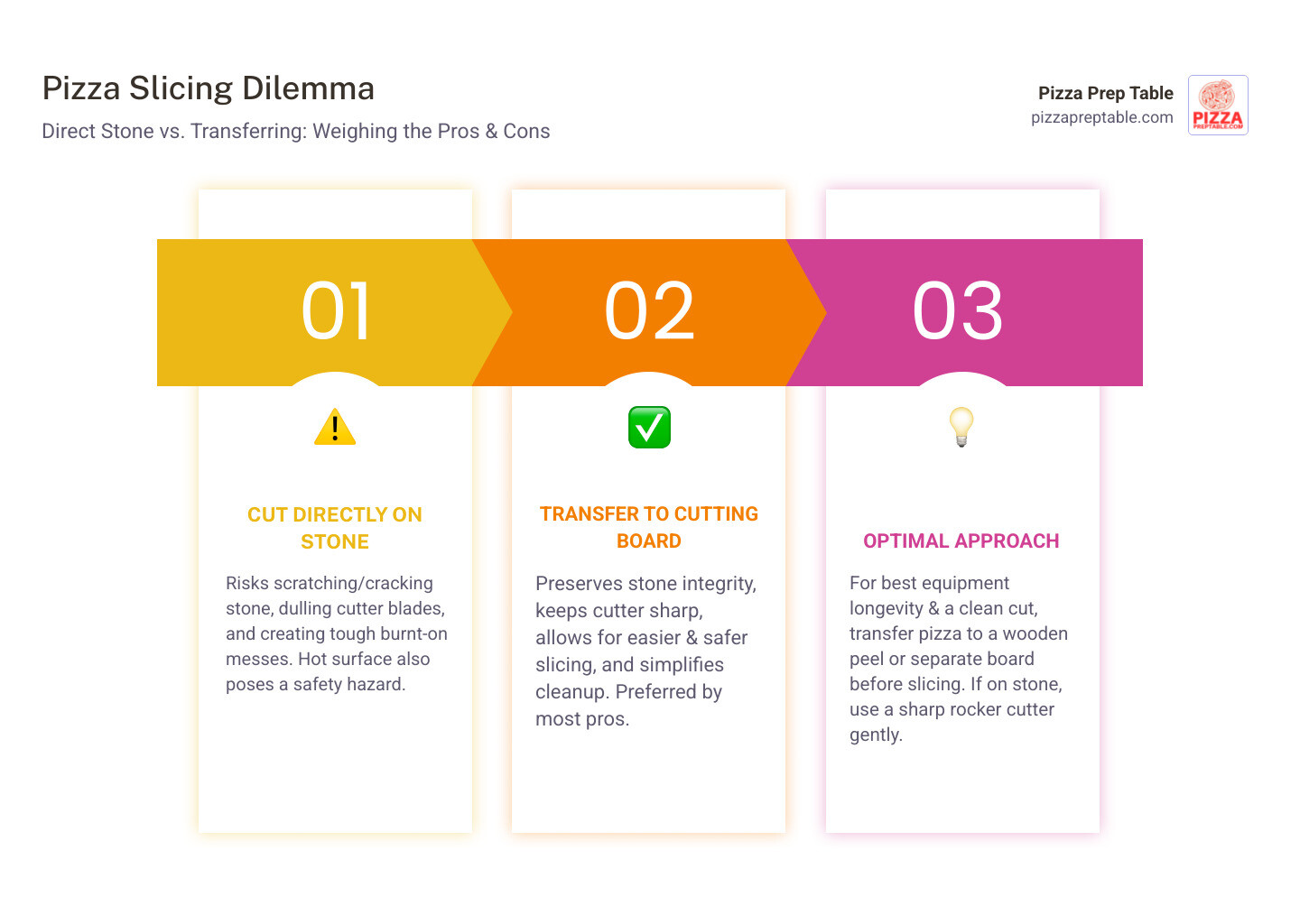

Pizza cutter on pizza stone usage is one of the most debated topics among pizzeria owners and home cooks alike. The quick answer? You can cut pizza directly on a pizza stone, but it requires the right technique and tools to avoid damaging your equipment.

Key Facts About Cutting on Pizza Stones:

- Stone durability: Most pizza stones can handle cutting, but may scratch or stain

- Heat factor: Stones stay extremely hot, making cutting difficult and potentially dangerous

- Best practice: Use a sharp, non-abrasive pizza cutter with decisive motions

- Alternative: Transfer pizza to a cutting board or metal tray before slicing

The research shows mixed opinions from professionals. As one forum user noted: "Cutting the pizza on the stone would be fine for the stone (it's quite sturdy), however, this would be hard to do because it's quite hot/heavy." Another expert warned: "When cutting the pizza, the sauce and cheese will melt onto the stone and cause black burn spots."

The reality is simple - while your pizza stone won't break from cutting, the process can create mess, burn spots, and dull your cutter faster. Most commercial kitchens transfer pizzas before slicing for good reason.

I'm Sean Kearney, and through my years in restaurant equipment sales, I've helped countless pizzeria owners choose the right tools for their operations, including finding the perfect pizza cutter on pizza stone combinations that work efficiently without damaging equipment. My experience has shown that proper cutting technique can make or break your kitchen's workflow and equipment longevity.

The Great Debate: Risks of Using a Pizza Cutter on a Pizza Stone

Picture this: your beautiful pizza emerges from the oven, cheese bubbling perfectly, crust golden brown. Your pizza stone has worked its magic, and now you're faced with the age-old question – should you slice it right there on the stone?

The short answer? It's complicated.

While you can use a pizza cutter on pizza stone, it's not always the best idea. Let me walk you through why this debate exists and what you need to know to make the right choice for your kitchen.

Understanding Your Pizza Stone's Material

The type of stone you're working with makes all the difference. Most pizza stones fall into three main categories, each with unique properties that affect how they handle cutting.

Cordierite stones are the workhorses of the pizza world. They resist thermal shock beautifully, meaning they won't crack when you move them from a hot oven to a cooler surface. However, they're still vulnerable to scratches from metal pizza cutters.

Ceramic stones are budget-friendly but trickier to work with. They're essentially kiln shelves designed for extreme heat, but they can crack if you don't preheat them properly. Their hard surface can quickly dull your cutter blades. If you're curious about the science behind ceramic materials, check out this in-depth look at ceramic properties that explains how these materials handle high temperatures.

Soapstone is the gentle giant of pizza stones. It's naturally porous and wicks away excess moisture, creating incredibly crispy crusts. Its softer nature might seem more forgiving to cutters, but it still shows scratches over time.

The Real Risks You're Taking

When you drag a metal blade across any stone surface, two things happen – and neither is great for your equipment.

Your cutter blade dulls fast. Think about it: you're pressing sharp metal against an abrasive surface repeatedly. As one industry expert puts it, this is a surefire way to "quickly destroy the edge of whatever you use to cut pizza." Nobody wants a dull cutter that tears through their beautiful pizza instead of slicing cleanly.

Your stone gets damaged. While pizza stones are "quite sturdy," they're not indestructible. You'll see scratches develop over time, creating grooves where food particles get trapped. Even worse are the black burn spots that appear when melted cheese and sauce seep into cuts and burn onto the stone's surface.

The Safety Factor

Here's something many people don't consider: pizza stones are dangerously hot when they come out of the oven – often over 500°F. Trying to apply pressure with a cutter while managing a heavy, scorching stone is asking for trouble. As one experienced cook wisely noted, "the stone is too hot, stone cannot be taken out of oven with pizza on it."

Burns and dropped stones aren't worth the convenience.

Why Most Chefs Advise Against It

Walk into any professional kitchen, and you'll hear the same advice: don't cut directly on your pizza stone. This isn't chef snobbery – it's practical wisdom based on equipment longevity and performance.

Professional consensus is clear: preserve your tools whenever possible. A pizza stone is an investment that should last years with proper care. Its porous surface absorbs moisture and maintains even heat distribution. Constantly scraping and cutting on it compromises these essential qualities.

Equipment preservation matters for your bottom line. When stones develop uneven heating or become harder to release pizzas from, your food quality suffers. The staining from burnt cheese and sauce isn't just unsightly – it affects the stone's non-stick properties and can even impart unwanted flavors to future pizzas.

Think of it this way: you wouldn't routinely cut food directly on your finest ceramic serving platter, right? The same logic applies to your pizza stone.

When Is It Okay to Cut on a Stone?

Despite the general advice against it, some situations make cutting on stones more acceptable.

Manufacturer recommendations matter most. Some companies design their pizza stone sets specifically for cutting. The All-Clad Gourmet Accessories 13-inch Pizza Baker Stone comes bundled with a serving tray and pizza cutter, suggesting the soapstone material can handle direct cutting. Similarly, the BergHOFF Leo Balance 14" Pizza Stone arrives as a complete set with its own cutter.

Soapstone properties make it slightly more forgiving than ceramic or cordierite. While it's softer and less likely to immediately dull your blade, it still shows wear over time. The key is understanding your specific stone's design and limitations.

Cut-safe stones do exist, but they're the exception, not the rule. If your manufacturer explicitly states their stone is designed for cutting, they've likely used materials or finishes that better withstand blade pressure. Even then, proper technique remains essential for preserving both your stone and cutter.

The balance between convenience and equipment care is delicate. When in doubt, check your manufacturer's guidelines and err on the side of caution.

Choosing the Right Tool for the Job

Look, if you're determined to use a pizza cutter on pizza stone, I get it. Sometimes convenience wins out, and that's perfectly fine. But here's the thing - choosing the right cutter can make all the difference between a smooth slicing experience and a disaster that damages both your stone and your blade.

After years of helping pizzeria owners select the right tools, I've seen what works and what doesn't. The truth is, not all pizza cutters are built for stone cutting. Some will scratch your beautiful stone, others will go dull after just a few uses, and the worst ones will do both while making a mess of your pizza.

Let me break down the two main types you'll encounter: rocker cutters and wheel cutters. Each has its place, but one clearly performs better when you're cutting directly on stone.

| Feature | Rocker Cutters (Mezzaluna) | Wheel Cutters (Rotary) |

|---|---|---|

| Blade Material | Often high-carbon stainless steel | Typically stainless steel |

| Handle Design | Two handles, ergonomic, sometimes non-slip | Single handle, ergonomic, varied materials |

| Ease of Use | Single, decisive rocking motion for clean cuts | Requires multiple passes, can drag toppings |

| Cleaning | Large, flat blade, easy to wipe clean | Wheel can be removable (Zyliss), some parts harder to clean |

| Best for Stone | Less dragging, potentially less abrasive on stone surface | Can scratch if not sharp or used with excessive force |

The Best Pizza Cutter for a Pizza Stone: Rocker vs. Wheel

Here's where things get interesting. In my experience working with commercial kitchens, there's a clear winner when it comes to stone cutting: the rocker cutter.

Think about it this way - when you use a rocker cutter (also called a mezzaluna), you're making one swift, decisive motion across your pizza. No dragging, no multiple passes, no grinding against the stone surface. Just one clean rock, and you're done. Many pizza pros swear by this approach, with some saying it's "the ONLY way to cut a pizza" because it doesn't push toppings around.

The BOLEXINO 20" High Carbon Stainless Steel Pizza Cutter Rocker is a perfect example of what to look for. Users rave about its sharpness and durability, with one reviewer boldly claiming, "You will not need to buy another pizza cutter in your life after this one." That's the kind of tool that can handle stone cutting without breaking a sweat.

Now, wheel cutters aren't completely out of the game. They're familiar, they're what most home cooks have, and some are genuinely well-made. The trick is finding one with sturdy construction and keeping it razor-sharp. Take the Pizza-Porta pizza cutter with its "4" Stainless Blade" - users love how "The wheel stays sharp, and the design allows good leverage."

But here's the reality: a dull wheel cutter on a pizza stone is a recipe for frustration. You'll end up pressing harder, scratching your stone, and tearing through your beautiful pizza instead of slicing it cleanly. If you're committed to using a wheel cutter, maintaining that sharp edge is absolutely crucial. Check out our guide on how to sharpen a pizza cutter to keep your blade in top condition.

For those running commercial operations, investing in quality tools is just as important as choosing the right ovens and equipment. You can explore commercial pizza ovens that pair perfectly with professional-grade cutting tools.

Materials Matter: What to Look For in a Cutter

Whether you go with a rocker or stick with a wheel, the materials and construction of your cutter will determine how well it performs on stone - and how long it lasts.

Stainless steel blades are absolutely essential. Don't even consider anything else. Look for high-quality options like 420J2 high-carbon stainless steel, which you'll find in top-tier rockers like the BOLEXINO. This material offers excellent corrosion resistance and holds a sharp edge beautifully. For commercial kitchens, high-carbon steel blades are worth the investment for their superior hardness and wear resistance.

Ergonomic handles might seem like a luxury, but they're actually a safety feature when you're working with hot stones. You need a comfortable, secure grip that won't slip when you're applying pressure. Look for non-slip grips made from materials like polypropylene or TPR, like those found on the BergHOFF Leo Balance set. The Zyliss Pizza Wheel is another great example, featuring an "ergonomic plastic handle for maximum control and safety."

Durability becomes critical if you're running a busy kitchen. The Pizza-Porta cutter's ability to handle "hundreds of pizza slices at an event" shows what real commercial-grade construction looks like. When you're serving customers in high-volume markets, you need tools that won't quit on you during the dinner rush.

Getting your entire prep station equipped with the right tools is just as important as choosing the perfect cutter. Make sure to find the right pizza prep tools that work together seamlessly for maximum efficiency.

How to Cut Pizza on a Stone: A Step-by-Step Guide

Now that you've chosen your perfect cutter, let's walk through the actual process of cutting pizza on a stone. Don't worry - with the right technique, you can slice your masterpiece without turning your kitchen into a disaster zone or damaging your precious stone.

The secret to success starts long before you even think about cutting. Preheating your stone properly sets the foundation for everything that follows. Give your stone a good 30-60 minutes to heat up at your target temperature (usually 450-550°F). This isn't just about getting a crispy crust - a thoroughly heated stone maintains consistent temperature better, which actually makes the cutting process safer and more predictable.

Once your pizza emerges from the oven with that gorgeous golden cheese and perfectly bubbled crust, resist the urge to dive in immediately. Baking is only half the battle - what happens next determines whether you'll have clean slices or a gooey mess.

Here's where patience pays off: let that pizza rest for 2-5 minutes before you even think about cutting. I know it's torture when that aroma is filling your kitchen, but this brief waiting period allows the cheese and toppings to set slightly. Without this rest, you'll end up with cheese sliding everywhere and sauce pooling in your cuts - not exactly the Instagram-worthy result you're after!

Now for the main event - the actual cutting technique. The approach depends entirely on your weapon of choice.

If you're using a rocker cutter, position the center of that curved blade right where you want your first slice. Apply firm, even pressure straight down, then rock the blade back and forth in one decisive motion. Think of it like a gentle see-saw movement - you want to cut through the entire crust in one smooth action. Lift, reposition, and repeat. The beauty of this method is that you're minimizing contact time with your stone.

For wheel cutter enthusiasts, start at the edge of your pizza and apply firm, consistent downward pressure. Push straight through using a smooth sawing motion if needed, but here's the crucial part - never drag that wheel sideways across your stone. That's a one-way ticket to scratch city.

Best Practices for Using a Pizza Cutter on a Pizza Stone

After years of helping pizzeria owners perfect their craft, I've seen what works and what doesn't when it comes to using a pizza cutter on pizza stone. Let me share the golden rules that separate the pros from the amateurs.

Sharp blades are non-negotiable. A razor-sharp cutter glides through your pizza with minimal pressure, which means less stress on your stone and cleaner cuts. If your cutter is struggling or tearing through the dough instead of slicing, it's time for a sharpening session. Trust me on this one - dull blades are the enemy of both your pizza and your stone.

That resting period we talked about? It's absolutely critical. Those few minutes allow everything to settle, making your cutting job infinitely easier. Think of it as letting your pizza compose itself before the grand finale.

Commit to your cuts with firm, decisive motions. Hesitation leads to jagged slices and unnecessary sawing back and forth. Whether you're rocking or rolling, make each movement count. Your stone will thank you for the efficiency.

Clean your cutter immediately after use - this isn't just about hygiene, it's about preserving your investment. Hardened cheese and sauce are much harder to remove later and can affect your cutter's performance.

On the flip side, never attempt this with a dull knife or cutter. It's like trying to cut paper with a butter knife - you'll end up applying way too much force and potentially damaging both your pizza and your stone.

Avoid dragging your cutter across the stone surface. This is especially important with wheel cutters. That sideways motion is what creates those unsightly scratches that never quite disappear.

Don't let enthusiasm turn into excessive force. Let the sharpness of your blade do the heavy lifting. Aggressive cutting is more likely to cause accidents or damage than create perfect slices.

Cleaning and Maintenance for Your Stone and Cutter

Proper maintenance is what separates equipment that lasts decades from gear that needs replacing every few years. When you're regularly using a pizza cutter on pizza stone, both pieces need special attention.

Your stone requires patience above all else. Never rush the cooling process - thermal shock from sudden temperature changes can crack even the sturdiest stone. Once it's completely cool, gently scrape off any stubborn cheese or sauce with a spatula or bench scraper. For really stuck-on bits, a stiff brush works wonders.

Here's something that surprises many home cooks: never use soap on your pizza stone. Ever. That porous surface will absorb the soap like a sponge, and trust me, soap-flavored pizza is not a culinary trend you want to start. Warm water and elbow grease are all you need. Those dark stains that develop over time? They're actually a good sign - consider them battle scars that show your stone is well-loved and properly seasoned.

After cleaning, pat your stone dry thoroughly and let it air dry completely before storing. Trapped moisture can lead to mold or even cracking in extreme cases.

Your cutter needs immediate attention after each use. Rinse off any cheese or sauce right away - once that stuff hardens, it becomes a real pain to remove. Even high-quality stainless steel can develop rust spots if left wet, so always dry your cutter completely after washing.

Regular sharpness checks should become second nature. A sharp cutter not only performs better but actually extends the life of your stone by requiring less pressure during cutting.

For our commercial clients, this maintenance routine becomes even more critical. Just like we help pizzerias in major markets maintain their prep stations, every tool in your arsenal deserves proper care. Make sure to maintain your commercial pizza oven parts with the same attention to detail you give your cutting tools.

Smart Alternatives to Cutting Directly on Your Stone

Let's be honest – while you can use a pizza cutter on pizza stone, there's often a smarter way to handle this situation. After years of helping pizzeria owners optimize their workflows, I've learned that the best solution isn't always the most obvious one. Sometimes, taking that extra 30 seconds to transfer your pizza can save you hours of frustration later.

Think about it this way: your pizza stone just spent an hour absorbing and radiating heat at 500°F. It's doing exactly what it was designed to do – creating that perfect, crispy crust we all crave. Why risk damaging this hardworking piece of equipment when there are simple alternatives that actually make your life easier?

Pizza peels are the professional's choice for good reason. Once your pizza emerges golden and bubbling from the oven, a quick slide with a wooden or metal peel moves it safely to your cutting surface. As one experienced cook puts it perfectly: "most people use a wooden pizza peel (like a flat wooden paddle) to remove the pizza from the stone before cutting it."

Wooden peels are particularly great because they double as both a transfer tool and a serving board. They're stable, look fantastic when you're entertaining, and won't dull your cutter's blade. Metal peels work beautifully for the transfer, though you'll want something more substantial underneath for actual cutting.

A sturdy cutting board transforms your pizza game. Whether you choose wood or plastic, you're giving yourself a stable, forgiving surface that welcomes your pizza cutter with open arms. No more worrying about scratches, no more burnt cheese welded to your stone's surface. Just clean, effortless cuts every single time.

For those who want a dedicated solution, aluminum pizza pans are purpose-built for this exact scenario. As our research shows, "An aluminum pizza pan is made for that purpose." These inexpensive rounds are tough enough to handle countless cuts, easy to clean, and won't break the bank if you need to replace them eventually. If you're curious about how different surfaces compare for pizza making, our guide on comparing cast iron vs pizza stone offers valuable insights.

Even a simple metal serving tray can be your pizza's best friend. One home cook shared their approach: "We transfer the pizza from the stone to a metal tray and cut it on the tray." It's straightforward, practical, and gets the job done without any fuss.

Here's what makes these alternatives so appealing: your equipment lasts longer, your cuts stay cleaner, and your stress levels drop dramatically. You're not juggling a blazing hot stone while trying to make precise cuts. Your pizza cutter stays sharp because it's not grinding against abrasive stone. Your stone stays pristine because melted cheese isn't burning into its pores.

The cleanup becomes a breeze too. Washing a cutting board or metal pan takes seconds compared to scraping burnt toppings off a porous stone surface.

While cutting directly on a stone won't destroy the world, choosing one of these alternatives is simply the smarter play. Your future self – and your equipment – will thank you for it.

Conclusion

After diving deep into pizza cutter on pizza stone techniques, one thing becomes crystal clear: pizza perfection isn't just about the dough, sauce, and toppings. How you handle that final, crucial step of slicing can make or break your entire pizza experience.

Throughout this journey, we've tackled the age-old debate head-on. Yes, you can cut pizza directly on your stone, but should you? The evidence points toward a more nuanced answer. Stone materials matter tremendously – while cordierite and ceramic stones can handle cutting, they're more likely to scratch and stain. Soapstone varieties, especially those sold as complete cutting sets, offer more forgiveness.

The tool you choose makes all the difference. A sharp rocker cutter that slices through in one decisive motion will always outperform a dull wheel cutter that drags and tears. As we finded, cutting on stone is a surefire way to destroy your blade's edge if you're not careful. High-carbon stainless steel blades paired with ergonomic, non-slip handles aren't just nice-to-haves – they're essential for anyone serious about their pizza game.

But here's what really struck me during my years helping pizzeria owners across Chicago, Miami, and beyond: the smartest operators almost always transfer their pizzas before cutting. There's wisdom in this approach that goes beyond just protecting equipment. A wooden peel sliding that perfect pizza onto a dedicated cutting board or metal tray isn't just safer – it's more efficient, cleaner, and ultimately leads to better results.

The safety factor can't be ignored either. Wrestling with a 500°F stone while trying to make precise cuts is asking for trouble. Those "black burn spots" from melted cheese aren't just unsightly – they can affect your stone's performance for years to come.

Whether you're perfecting your home pizza nights or running a busy commercial kitchen, these techniques and tool choices will serve you well. At PizzaPrepTable.com, we've seen how the right equipment and knowledge transform pizza operations from good to exceptional. Every detail truly does count when you're chasing pizza perfection.

Ready to take your pizza game to the next level? Explore our comprehensive your guide to restaurant and pizza equipment and find how the right prep tables and equipment can lift every aspect of your pizza-making process.