Slice, Dice, Chill & Thrill with These Top Food Preparation Tables

Share

Why Every Commercial Kitchen Needs the Right Food Preparation Table

A food preparation table is the backbone of any commercial kitchen, serving as a dedicated workspace for chopping, slicing, mixing, and assembling ingredients safely and efficiently. Whether you're running a pizzeria, sandwich shop, or full-service restaurant, the right prep table can make or break your kitchen's workflow.

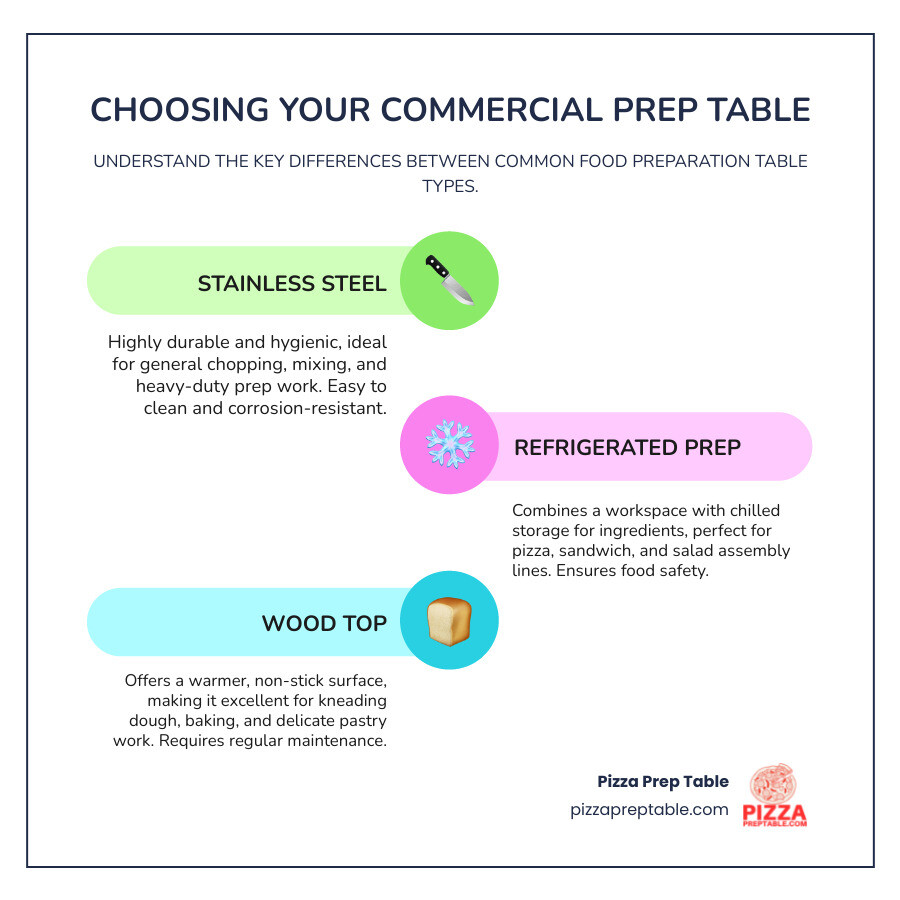

Key Types of Food Preparation Tables:

- Stainless Steel Work Tables - Durable, easy to clean, ideal for general prep work

- Refrigerated Prep Tables - Keep ingredients cold while you work, perfect for pizza and sandwich stations

- Wood Top Tables - Best for dough prep and baking applications

- Mobile Prep Carts - Flexible workspace that moves where you need it

Essential Features to Consider:

- Material: 304-grade stainless steel for food contact, 430-grade for equipment stands

- Size: Standard 30" depth, lengths from 24" to 96"

- Load Capacity: Heavy-duty tables support up to 1,400 lbs

- Certifications: NSF listing required for commercial foodservice

- Storage: Undershelves, drawers, or refrigerated bases for efficiency

As research shows, "prep tables are vital for any restaurant or cafeteria" and serve as the foundation for organized, methodical food preparation that keeps your kitchen running smoothly.

I'm Sean Kearney, and my background in sales has taught me that having the right food preparation table can make all the difference in a restaurant's efficiency and profitability. From my early days selling equipment to major restaurant chains, I've seen how quality prep tables transform kitchen operations.

From Gaming Worlds to Gourmet Kitchens: Understanding the Modern Prep Table

Here's something interesting: when people search for "food preparation table," they're not all looking for the same thing. Some are thinking about busy restaurant kitchens with chefs chopping vegetables. Others? They're Viking warriors trying to survive in a digital Norse world.

Let me explain this fascinating split that shows just how diverse our modern world has become.

For the Viking Chefs: The Valheim Food Preparation Table

If you've ever played Valheim, you know that food isn't just about staying alive – it's your ticket to becoming a legendary Viking. The food preparation table in this survival game is actually a crafting station that transforms your character from a weak newcomer into a formidable warrior.

Building one is refreshingly simple. Just gather 4 Flint and 2 Wood near a Workbench, and you're ready to start your culinary trip. But here's where it gets exciting: this isn't just about making basic meals.

With your food preparation table, you can create impressive dishes like "Whole roasted Meadow boar" or a "Black Forest buffet platter." These aren't just fancy names – they provide serious health buffs and stamina buffs that let you run further without collapsing in exhaustion. The smart players eat three different foods at once to maximize their buffs, turning meal planning into genuine strategy.

Trust me, when you're facing down Greydwarfs or sailing across dangerous seas, good food preparation can mean the difference between victory and respawn. The gameplay impact is real, and the Valheim Wiki has all the recipes you need to become a master Viking chef.

For the Professional Kitchen: The Commercial Food Preparation Table

Now let's step out of the gaming world and into real kitchens where the stakes are just as high, but the rewards are measured in satisfied customers and profitable businesses.

In commercial use, a food preparation table becomes the heartbeat of your operation. Whether you're running a pizza shop in Chicago or a sandwich counter in New York, this equipment determines how smoothly your kitchen flows.

Foodservice establishments depend on these tables for everything from chopping vegetables to kneading dough to assembling complex dishes. But it's not just about having a flat surface – it's about hygiene, durability, and meeting strict health codes.

This is where NSF certification becomes crucial. These standards ensure your table can handle the demands of commercial food service while keeping your customers safe. When we talk about reducing cross-contamination, we're talking about protecting your business reputation and your customers' health.

The right food preparation table transforms chaos into organized efficiency. It's the difference between staff bumping into each other and a kitchen that hums like a well-oiled machine. As we detail in our guide Table Talk: Restaurant Kitchen Prep Tables Explained, choosing the right prep table is one of the most important decisions you'll make for your kitchen's success.

Whether you're conquering digital worlds or real-world dinner rushes, the right preparation surface makes all the difference.

Key Features to Consider in a Commercial Food Preparation Table

When you're shopping for the perfect food preparation table for your commercial kitchen, it's easy to think "a table is just a table." Trust me, I've heard that from countless restaurant owners over the years. But here's the thing – the right prep table can transform your kitchen from chaotic to choreographed, while the wrong one can become a daily source of frustration.

Think of your food preparation table as the Swiss Army knife of your kitchen. It needs to handle everything from delicate herb chopping to heavy-duty dough kneading, all while meeting strict health department standards. Let's explore what really matters when making this crucial investment.

Material Matters: Choosing Between Stainless Steel, Wood, and Poly Tops

The material you choose for your food preparation table top isn't just about looks – it's about performance, longevity, and food safety. Each material has its own personality and purpose in the commercial kitchen world.

Stainless steel is the workhorse of commercial kitchens, and for good reason. It's like that reliable friend who's always there when you need them – durable, easy to clean, and ready for anything. But not all stainless steel is created equal, and understanding the differences can save you money and headaches down the road.

304-grade stainless steel is the premium choice, often called 18/8 stainless because it contains 18% chromium and 8% nickel. This combination makes it incredibly resistant to corrosion from salt and acidic foods – perfect for surfaces that see constant food contact. When you're prepping marinara sauce or handling salty ingredients all day, this grade won't let you down.

430-grade stainless steel contains less nickel (about 17% chromium) and offers a more budget-friendly option. It's still durable and professional-looking, making it ideal for equipment stands, undershelves, or areas where direct food contact isn't constant. Think of it as the practical choice for supporting roles in your kitchen setup.

Metal gauge is another crucial factor – and here's where it gets a bit backwards. The smaller the gauge number, the thicker and stronger the steel. For heavy-duty prep work, look for 14-gauge tops that can handle serious abuse, while 16 or 18-gauge works fine for lighter applications or undershelves.

Butcher block and wood tops bring a completely different energy to your kitchen. Made from maple or oak, these surfaces are incredibly gentle on knife blades and provide natural shock absorption for chopping and pounding. Bakers especially love wood tops for dough preparation – the surface provides just the right amount of grip without sticking. The end-grain construction even offers "self-healing" properties as the wood fibers close up after cutting.

Poly-Vance tops are the newcomers making waves in commercial kitchens. These specialized plastic surfaces excel at preventing cross-contamination because you can dedicate different colored tops to different food types. Raw meat gets the red top, vegetables get the green – it's food safety made visual and foolproof.

Industry best practices suggest using 304 stainless for surfaces that directly contact food, especially salty or acidic products, while 430 stainless works great for extending countertops or holding equipment.

Essential Features for a High-Functioning Food Preparation Table

Beyond the tabletop material, the right features can turn a basic food preparation table into a productivity powerhouse. These aren't just nice-to-haves – they're the details that separate a good prep table from a great one.

A backsplash might seem like a small detail, but it's a game-changer if your table sits against a wall. This vertical panel catches flying food bits, splashing liquids, and prevents utensils from disappearing into that dreaded gap behind your table. Available in heights from 1.5 to 10 inches, it keeps your walls clean and makes end-of-day cleanup much less painful.

The undershelf is like having a secret storage compartment. Most commercial prep tables include an adjustable shelf underneath that holds pots, pans, ingredients, or small appliances right where you need them. It's amazing how much more organized your workflow becomes when everything has its place within arm's reach.

Casters for mobility transform your static prep table into a flexible workstation. Heavy-duty wheels let you reconfigure your kitchen layout for deep cleaning, move prep work closer to cooking stations, or even roll your setup outside for catering events. Some casters are built tough enough for outdoor terrain – perfect for food trucks or outdoor events.

Integrated sinks are the ultimate multitaskers for operations requiring frequent washing and rinsing. These units combine prep space with washing capability, often including faucets, drains, and sometimes a cutting board that fits over one sink compartment. It's like having a compact prep and wash station all in one footprint.

For pizzerias and sandwich shops, a refrigerated base is absolutely revolutionary. These units combine a work surface with refrigerated storage underneath, featuring pan rails on top for ingredient containers and a cutting board along the front. Your cheese, pepperoni, and vegetables stay perfectly chilled while remaining easily accessible – it's food safety and speed of service rolled into one smart package. Our detailed guide on the Sandwich Prep Table Refrigerator explores all the benefits these units bring to busy kitchens.

Integrated drawers offer secure storage for utensils, measuring tools, and specialty ingredients that need to stay separate and organized. They're particularly valuable in bakeries where precise measuring tools and specialty ingredients need their own dedicated space.

When it comes to load capacity, commercial food preparation tables are built to handle serious weight – some supporting up to 1,400 pounds. They're also available in an impressive range of sizes, from compact 24-inch lengths perfect for tight spaces to expansive 96-inch units for high-volume operations. Heights range from 21 to 65 inches, and widths from 21 to 72 inches, ensuring you can find the perfect fit whether you're running a cozy neighborhood pizzeria or a busy downtown restaurant.

Our Top Picks for Commercial Prep Tables in 2024

When I walk through different commercial kitchens across the country, from busy pizzerias in Boston to high-volume bakeries in San Francisco, I see the same thing over and over: the right food preparation table transforms chaos into smooth, efficient operations. At PizzaPrepTable.com, we've helped thousands of foodservice businesses find their perfect match, and these are the tables that consistently deliver exceptional results.

The All-Rounder: Heavy-Duty Stainless Steel Work Table

Think of a heavy-duty stainless steel work table as the Swiss Army knife of commercial kitchens. These tables are the quiet workhorses that handle everything you throw at them, day after day, without complaint. I've seen the same Eagle Group table in a Houston restaurant still going strong after fifteen years of constant use.

The beauty of these tables lies in their durability. Built with high-gauge stainless steel (usually 14 or 16 gauge for the top), they can handle the heaviest mixing bowls, the most aggressive chopping, and loads that would make other surfaces buckle. The 304-grade stainless steel construction means they resist corrosion from acidic ingredients like tomatoes and citrus, keeping that professional shine year after year.

What makes them truly versatile is their adaptability. Need a space for prepping vegetables? Perfect. Want to use it as a station for portioning meat? Done. Looking for a sturdy base for your commercial mixer? It handles that too. The flat top design maximizes your usable space, which is gold in cramped kitchen environments.

Cleaning is where these tables really shine. After a busy dinner rush, a quick wipe-down with mild detergent followed by sanitization is all it takes. No special treatments, no fussy maintenance – just reliable cleanliness that health inspectors love to see.

Eagle Group has earned its reputation through tables that feature patented uni-lok recessed gusset designs for rock-solid stability. Gridmann offers excellent value with commercial-grade construction that serious home chefs often choose for their personal kitchens. Both brands typically include that crucial adjustable undershelf, letting you customize storage for different equipment heights.

Whether you're setting up a new restaurant or upgrading an existing kitchen, a quality stainless steel work table forms the foundation of efficient food prep. Check out more options in our guide to Prep Tables For Restaurant.

The Chill Factor: Refrigerated Pizza & Sandwich Prep Table

Here's where the magic happens for pizzerias, delis, and sandwich shops. A refrigerated food preparation table isn't just convenient – it's the difference between smooth service and constant chaos during lunch rush. I've watched pizza makers in Chicago work like artists, pulling fresh toppings from chilled pans just inches away while assembling perfect pies.

The ingredient storage setup is brilliantly simple. Standard-sized pans fit perfectly into cutouts on top, keeping everything from sliced pepperoni to fresh mozzarella at safe temperatures. No more running back and forth to the walk-in cooler every few minutes. The integrated cutting board runs along the front, creating a seamless workflow where you grab, assemble, and slice all in one spot.

Below the work surface, the refrigerated base provides backup storage for bulk ingredients and extra pans. This means you can prep for busy periods without worrying about running out of popular toppings mid-rush. Most importantly, these units maintain temperatures below 41°F, keeping your ingredients in the safe zone that health departments require.

Atosa has built a strong following with reliable, energy-efficient units that come in various sizes to match your volume needs. Dukers provides solid construction with stainless steel interiors that make daily cleaning straightforward. Both brands understand that in a busy kitchen, your equipment needs to work as hard as you do.

Picture assembling a custom pizza in San Antonio or crafting a gourmet sandwich in Philadelphia with every fresh ingredient perfectly chilled and within arm's reach. That's the efficiency boost a refrigerated prep table delivers. Learn more about these specialized units in our Commercial Pizza Prep Table guide.

The Baker's Delight: Wood Top Dough Prep Table

For bakers and pizza makers who work with dough daily, a wood top food preparation table is like having a skilled assistant. The natural properties of wood create the perfect environment for kneading, rolling, and shaping dough – something stainless steel simply can't match.

Hard maple or oak butcher block provides just the right amount of grip without being sticky. The wood's slightly porous surface helps with dough handling while staying gentle enough that it won't tear delicate pastry. Unlike cold stainless steel, wood maintains a more neutral temperature that dough responds to beautifully.

These tables are built like tanks to handle the repetitive pressure of daily kneading and rolling. Their substantial thickness and sturdy construction mean they won't wobble or shift when you're working with heavy batches of bread dough. Some models include raised edges or flour bins to keep your workspace tidy – a small detail that makes a big difference during busy baking sessions.

John Boos represents the gold standard in butcher block construction. Their tables are investments that last decades, with craftsmanship that shows in every detail. Yes, they cost more upfront, but ask any baker in Austin or Columbus who owns one – they'll tell you it's worth every penny.

The aesthetic appeal is just a bonus. In open-concept kitchens or bakeries where customers can see the preparation area, a beautiful wood table adds warmth and authenticity that customers notice and appreciate.

For insights on how these tables work alongside other baking equipment, explore our article Doughn't Settle For Less: Choosing The Perfect Pizza Preparation Refrigerator.

Frequently Asked Questions about Food Prep Tables

Running a commercial kitchen means dealing with endless questions, and we've heard them all when it comes to food preparation tables. Whether you're a seasoned chef in Miami or opening your first pizza shop in Portland, these are the answers that'll keep your kitchen running like a well-oiled machine.

How do I properly clean and sanitize a food preparation table?

Here's something that trips up a lot of kitchen managers: cleaning and sanitizing are two completely different steps. Miss one, and you're not doing your job right.

Start with cleaning – this is about getting rid of what you can see. Scrape off those food bits first, then grab a microfiber cloth with warm soapy water. For stainless steel tables, here's a pro tip: always wipe with the grain, not against it. Those little lines you see aren't just for looks – they're your roadmap to a streak-free finish. Skip the steel wool and wire brushes unless you want to turn your beautiful prep table into a scratched-up mess.

Rinsing comes next – wash away every trace of soap with clean water. No shortcuts here.

Now for the sanitizing magic. This is where you kill the nasties you can't see. Use a food-safe sanitizing solution and let it sit for the time listed on the bottle (usually 30 seconds to a few minutes). Here's the key part: let it air dry completely. Don't wipe it off right away – that sanitizer needs time to do its bacteria-fighting work.

This two-step dance prevents cross-contamination and keeps your customers safe, whether you're slinging pizzas in Vegas or crafting gourmet sandwiches in Charlotte.

What is the difference between 304 and 430 grade stainless steel?

Think of stainless steel grades like choosing between a luxury car and a reliable daily driver – both will get you where you're going, but one handles rough conditions better.

304-grade stainless steel (also called 18/8 steel) is your premium choice. With 18% chromium and 8% nickel, it laughs in the face of acidic tomato sauce and salty environments. It's non-magnetic, incredibly durable, and perfect for any surface that touches food directly. If you're prepping fresh ingredients all day, this is your best friend.

430-grade stainless steel contains 17% chromium but very little nickel. It's magnetic, more budget-friendly, and still plenty tough for commercial use. The trade-off? It's not quite as bulletproof against acids and salt. This makes it perfect for undershelves, legs, and equipment stands where food contact isn't constant.

The smart move? Use 304-grade for your work surface and 430-grade for the supporting parts. You get the protection where you need it most without breaking the bank.

Do I really need a backsplash on my prep table?

Short answer: if your food preparation table sits against a wall, absolutely yes. Long answer: let me tell you why this little vertical panel is worth every penny.

Picture this: you're chopping onions during the dinner rush, and a piece goes flying. Without a backsplash, it disappears into that mysterious space between your table and the wall. Good luck fishing it out during service! A backsplash acts like a safety net, keeping food, liquids, and runaway utensils where they belong.

Cleaning becomes a breeze when you're not trying to reach into impossible crevices with a mop. Those hard-to-reach spots are where bacteria love to throw their own little parties, and trust me, you don't want to be the host.

From a hygiene standpoint, backsplashes are contamination fighters. They contain splashes and spills, making it much easier to keep your kitchen up to health department standards. Plus, they protect your walls from the daily battle scars of commercial cooking – grease stains, food splatter, and moisture damage.

The small upfront cost pays for itself in easier maintenance, better hygiene, and fewer headaches down the road. It's one of those "why didn't I do this sooner?" moments.

Conclusion: Find the Perfect Prep Table for Your Business

Choosing the right food preparation table is one of the smartest investments you'll make for your kitchen. It's not just about having a place to chop vegetables – it's about creating a workspace that makes your team more efficient, keeps your food safer, and helps your business run like a well-oiled machine.

Think about it this way: your prep table is where the magic happens. Whether you're running a cozy pizzeria in Portland or a busy sandwich shop in Miami, the right table becomes the heart of your operation. Your staff will spend hours at this surface every single day, so it needs to work as hard as they do.

The material you choose sets the foundation for everything else. Stainless steel gives you that bulletproof durability and easy cleanup that health inspectors love to see. Wood tops transform your dough prep from a chore into an art form. And those refrigerated models? They're like having a sous chef that never takes a break, keeping your ingredients perfectly chilled and within arm's reach.

Size and features matter more than you might think. A backsplash saves you from playing hide-and-seek with runaway ingredients behind your table. An undershelf doubles your storage without taking up extra floor space. And if you've ever tried to move a heavy table during a deep clean, you'll understand why casters can be a real back-saver.

At PizzaPrepTable.com, we've seen how the right equipment transforms kitchens from coast to coast. From the busy delis of San Diego to the gourmet restaurants of Washington, D.C., success starts with having the right foundation. We know that whether you're a small independent shop just starting out or a larger establishment looking to upgrade, finding quality equipment that fits your budget is crucial.

That's why we offer financing options alongside our wide selection of high-quality tables. Because every foodservice business deserves equipment that empowers their team to do their best work, regardless of size or budget.

Ready to find your perfect match? Explore our complete collection of Pizza Prep Tables and find how the right food preparation table can take your kitchen to the next level. Your future self (and your staff) will thank you.