Your Deli's Dream Machine: Finding the Perfect Sandwich Prep Cooler

Share

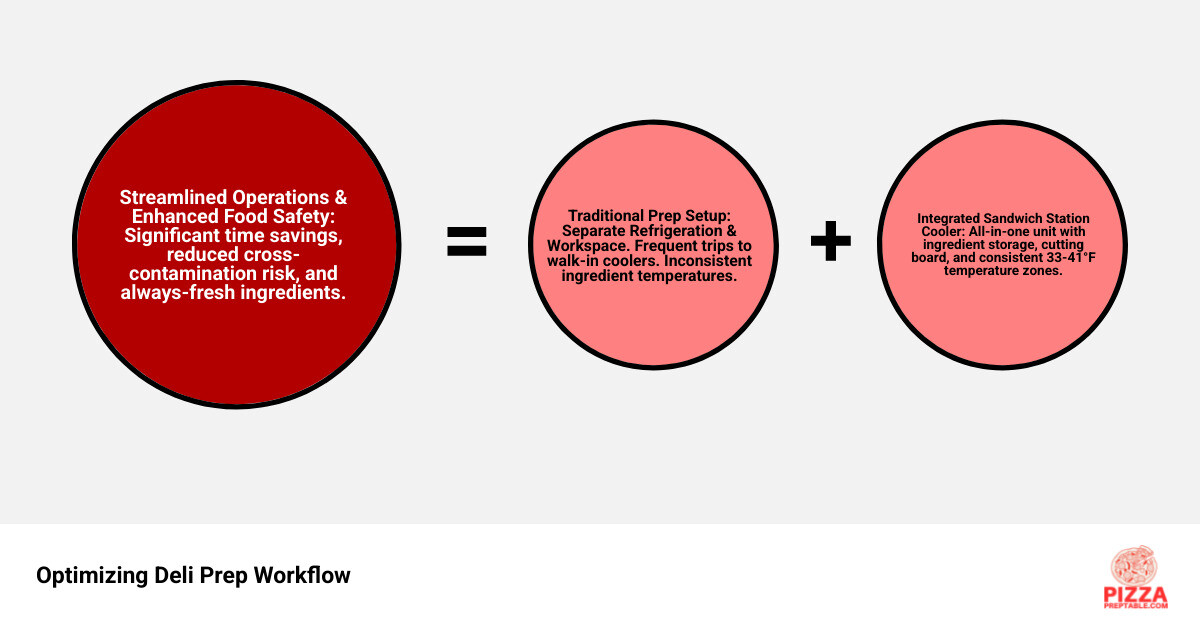

Why Your Deli Needs a Sandwich Station Cooler

A sandwich station cooler is a refrigerated prep table combining ingredient storage with a workspace. It keeps components at safe temperatures (33-41°F) for easy access during food preparation. Key benefits include:

Essential Features:

- Temperature Control: Maintains ingredients below 41°F to prevent bacterial growth

- Organized Storage: Food pans keep ingredients separated and accessible

- Workspace Integration: Built-in cutting board for efficient prep

- Food Safety Compliance: NSF-certified models meet health department standards

Popular Sizes:

- 27-inch: Perfect for small cafes and delis

- 48-inch: Standard choice for most restaurants

- 60-72-inch: High-volume operations and large kitchens

With salads making up 40% of US lunches and the commercial refrigeration market projected to hit $45.5 billion by 2027, having the right prep equipment is critical for your deli's success.

A quality sandwich station cooler transforms your kitchen workflow by eliminating trips between storage and prep stations. Instead of opening walk-in coolers or separate refrigerators, everything you need is at your fingertips at the perfect temperature.

I'm Sean Kearney, and my sales background has shown me that the right sandwich station cooler is crucial for a deli's efficiency and profitability. I've helped everyone from small cafes to large chains select equipment and have seen how it transforms kitchen operations.

Choosing Your Perfect Fit: Types and Features of Sandwich Station Coolers

Finding the right sandwich station cooler means matching it to your kitchen's pace and space to keep ingredients chilled during the lunch rush. Let's walk through the key decisions to help you pick the ideal unit.

Full-Size vs. Countertop: Sizing Up Your Needs

The first choice is between a full-size unit and a countertop model. This decision is about matching the equipment to your business volume and operational style, not just your available space.

Full-size units are workhorses that range from 27 to 93 inches wide. They are built with ample refrigerated storage underneath the prep surface, usually behind multiple doors or drawers. A 48-inch model is a good fit for most restaurants, while busier establishments might need 60-inch or 72-inch units to keep up with demand.

These standalone stations offer significant prep space and ingredient capacity. If sandwiches, salads, or wraps are central to your menu and you have high volume during peak hours, a full-size unit is your best bet.

Countertop units are space-saving solutions for smaller operations. Models like the Atosa Stainless Steel Refrigerated Countertop Prep Station (50" W) or the Arctic Air ACP48 (47.25" W) sit on an existing counter, providing a refrigerated pan rail and compact cutting surface without using floor space.

While they lack the under-counter storage of larger units, they excel at keeping frequently used ingredients chilled and accessible. These compact solutions are game-changers for food trucks, where every square inch counts and having fresh ingredients in a small footprint is essential.

If you're working with limited space, check out our guides on Sandwiches Made Simple with Countertop Prep Stations and Food Truck Fridges: Your Top Picks for Mobile Cooling.

A busy deli might need multiple full-size units, while a coffee shop could be satisfied with a countertop model for occasional sandwich orders.

Essential Features for Efficiency and Safety

Certain features separate a great sandwich station cooler from an average one. These aren't just nice-to-haves; they're essential for a smooth operation.

Stainless steel construction is a must-have. Commercial-grade stainless steel is essential for durability, resisting rust and corrosion, and easy cleaning. It ensures your unit remains professional and sanitary for years.

Digital temperature control is another non-negotiable feature. You need precise control to keep ingredients like meats, cheeses, and vegetables safely below 41°F. Maxx Cold's X-Series achieves this with a temperature range of 33°F to 41°F. An external display allows you to check temperatures without opening the unit and letting cold air escape.

NSF certification provides peace of mind. An NSF stamp means the equipment meets strict public health and safety standards. Units like the Everest EPBNR2 carry this certification, ensuring you meet health department requirements.

ENERGY STAR ratings are becoming more common as energy costs rise. These certified units use less power, leading to real savings on your utility bills over time.

Don't overlook cutting board depth. The Maxx Cold X-Series has an 11.42-inch deep cutting board, while the KOOL-IT offers a removable 9.5-inch board. Those extra inches matter during the lunch rush.

Other smart features include removable hoods for easy cleaning, reversible doors to fit your layout, and self-closing doors with magnetic gaskets (like on the KOOL-IT) that help maintain consistent temperatures.

Casters with brakes are another valuable feature. Units like the Maxx Cold X-Series and Everest EPBNR2 roll easily for cleaning or rearranging, then lock securely in place. For more insights on keeping ingredients fresh, see Freshness Guaranteed with These Sandwich Prep Refrigerators.

Customizing Your Setup: Mega Tops, Doors, and Drawers

The magic of a sandwich station cooler often comes down to customizing it to your specific workflow.

The choice between a standard top and mega top unit can significantly impact daily operations. A standard top has a flat, refrigerated pan rail with the cutting board in front. A mega top features a deeper, wider pan rail that can hold more or larger food pans, putting more ingredients at your fingertips.

Atosa's mega top refrigerated sandwich prep tables are perfect examples of this extra capacity. During busy lunch rushes, you'll spend less time restocking because everything you need is right there.

Pan capacity is tied to your top choice and unit length. A Maxx Cold X-Series Two-Door unit holds 16 pans, while a KOOL-IT accommodates sixteen 1/6 pans. The flexibility comes from mixing and matching pan sizes (1/3, 1/6, 1/9) within the same rail system to fit your workflow.

The door and drawer configuration underneath is for backup supplies and bulk ingredients. You can choose units with one, two, or three doors. Some models offer drawers instead of or alongside doors, which are great for organizing smaller or frequently accessed items.

Think through your daily routine: How do you organize? Which ingredients do you use fastest? How much backup stock do you need? Answering these questions will make the right configuration clear.

Our Top-Rated Sandwich Prep Coolers for 2024

Here are some of the most popular and highly-rated models available from PizzaPrepTable.com, designed to meet the demands of any commercial kitchen.

After helping countless restaurant owners, I've seen which sandwich station coolers deliver reliable, daily performance. These are the workhorses that keep kitchens running smoothly, not just the models with the flashiest features.

Best for High-Volume Kitchens: True TPP-93

For kitchens producing hundreds of sandwiches during the lunch rush, the True TPP-93 is the reliable workhorse high-volume operations depend on.

This impressive 93-inch wide unit features a 3-door design with massive refrigerated storage. True Refrigeration has a reputation for equipment that lasts for decades, and the TPP-93 embodies that with its robust construction and powerful refrigeration system.

What makes this unit special is its durability from True's commercial-grade engineering. Many delis use the same True unit for over 15 years, and it still maintains perfect temperatures. The high capacity pan rail means you can stock every topping without constantly restocking during busy periods.

If you're running a large deli, cafeteria, or restaurant where sandwiches are a major revenue driver, this unit pays for itself through sheer reliability. Check out our full selection of True pizza prep table models, and find why three-door units are game-changers in our guide 3-Door Pizza Prep Fridges That'll Make You Say Cheese.

Best Value and Performance: Atosa MSF8302 Mega Top

The Atosa MSF8302 Mega Top proves you can get professional-grade performance without breaking the bank.

At 48 inches wide, this unit is ideal for most operations. The mega top capacity provides extra room for ingredient pans right at your fingertips, which means less reaching, less restocking, and more sandwiches made per hour.

Atosa delivers affordability without cutting corners on essentials like durable stainless steel construction. I've recommended this model to many small restaurant owners, and the feedback is consistently positive: it performs like a much more expensive unit.

The mega top design is particularly useful for sandwich shops, allowing you to organize popular toppings in the extended pan rail while keeping backups chilled below. Browse our complete Atosa pizza prep table collection to see why this brand is a favorite among budget-conscious operators.

The All-Rounder: Beverage-Air SPE48-12

The Beverage-Air SPE48-12 is a versatile unit that excels in all areas.

This 48-inch width unit with a 2-door design represents decades of refinement from a respected name in commercial refrigeration. Beverage-Air's brand reputation is earned through consistent performance in thousands of kitchens.

This unit's versatility comes from its balanced approach. The temperature control is precise, the construction is robust, the refrigerated storage is spacious, and the prep surface is sized for an efficient workflow.

I often recommend this model to operators unsure of their peak volume. It scales beautifully, handling both quiet periods and busy rushes with ease. Learn more about maximizing two-door efficiency in our article Slice and Dice with Ease: 2-Door Pizza Prep Fridges Reviewed.

Best Compact Footprint: Maxx Cold MXCR-27S

For small cafes and delis with tight quarters, the Maxx Cold MXCR-27S is a space-saving solution.

This 27-inch width, single door unit packs impressive functionality into its compact footprint. It's perfect for coffee shops adding sandwiches to their menu, small delis with limited floor space, or as a secondary station in larger kitchens.

The genius of this unit is that it doesn't sacrifice key features. You still get proper refrigerated pan storage, a functional cutting board, and reliable temperature control.

I've seen this unit transform tiny operations. One coffee shop owner told me it doubled their lunch sales because they could finally offer fresh, made-to-order sandwiches without dedicating half their kitchen to prep equipment. For more compact solutions, check out our insights on Small Undercounter Refrigerator options.

Maximizing Your Investment: Cost, Care, and Accessories

A sandwich station cooler is a significant investment. To get the most value, it's important to understand the factors that drive cost, how to maintain your unit, and which accessories will improve its function. Let's break down what you need to know.

What Influences the Cost of a Sandwich Station Cooler?

Prices for a sandwich station cooler can range from $1,500 to over $10,000. Understanding what drives these differences helps you make a smart choice that fits your needs and budget.

Size matters most when it comes to pricing. A compact 27-inch unit will cost much less than a massive 93-inch powerhouse. You're paying for space, pan capacity, and greater cubic feet of refrigerated storage.

Brand reputation plays a huge role. Established names like True Refrigeration and Beverage-Air command premium pricing through proven performance. A high-end True model might reach over $10,000, while reliable Maxx Cold units typically fall in the $2,000-$3,500 range. You're investing in durability and comprehensive warranties.

The features and technology packed into your unit can increase the price. Units with mega tops, multiple doors or drawers, advanced digital controls, or specialized cooling systems like Everest's "Blizzard R290 All-In-One Slide Out Cooling Cartridge" will cost more upfront but can save you money long-term through better performance and efficiency.

Material quality and energy efficiency are other major cost factors. While most commercial units use stainless steel, the gauge and quality can vary. ENERGY STAR certified models might cost more initially but can lead to substantial savings on your utility bills.

The lowest price isn't always the best value. We understand these are major investments, which is why we offer flexible financing options to help make these essential purchases more manageable.

Proactive Maintenance for Your Sandwich Station Cooler

Your sandwich station cooler works hard every day. Regular maintenance is a crucial investment to ensure it runs reliably for years and helps you avoid equipment failures during a busy lunch rush.

Daily cleaning is your first line of defense. Wipe down the stainless steel surfaces, cutting board, and pan rail with a food-safe cleaner at the end of each day. Many units, like Beverage-Air models, feature removable hoods and easy-to-clean surfaces. Clean under and around the food pans where crumbs and spills can hide.

Gasket care is straightforward. Regularly inspect the rubber door seals for cracks or tears, and clean them with warm, soapy water. Units from Everest and KOOL-IT make this easier with snap-in, magnetic gaskets.

Condenser coil cleaning is critical. These coils can accumulate dust and grease, forcing your unit to work harder, use more energy, and wear out faster. Clean them monthly in busy kitchens (quarterly for lighter use) with a brush or vacuum. Some advanced units, like the Everest EPBNR2, feature reverse fan motors that help keep coils cleaner automatically.

For detailed maintenance instructions, always check the manufacturer's manual. Here's an example of the Maxx Cold Manual to see what to expect.

Essential Accessories for a Complete Station

Your sandwich station cooler is great on its own, but the right accessories transform it into a highly efficient workstation. These tools help your staff work faster, stay organized, and maintain high food safety standards.

Food pans are essential, and you'll want plenty in various sizes. Standard 1/3, 1/6, and 1/9 pan sizes fit in your pan rail. You can choose between polycarbonate pans (durable, clear) and stainless steel pans (robust, better temperature retention). Always look for NSF-certified options like the CURTA food pans.

Squeeze bottles are game-changers for applying dressings and sauces cleanly and consistently. Pan dividers help organize ingredients within larger pans, and many units like the Maxx Cold X-Series include clip-on divider bars.

Don't overlook replacement cutting boards. Your integrated cutting board takes a beating, so having clean spares ready ensures a sanitary surface. This is especially useful if your unit has a removable board like the VEVOR or KOOL-IT models.

Round out your setup with under-shelf storage containers and consider a nearby conveyor toaster if your menu includes toasted items. These additions create a seamless workflow for your team.

Frequently Asked Questions

Let's tackle some of the most common questions we hear about sandwich station coolers. These answers will help clear up any confusion and guide you toward the best choice for your kitchen.

How does a refrigerated prep table improve food safety?

A sandwich station cooler is a guardian of food safety. Its primary role is to keep ingredients out of the "temperature danger zone" (41°F to 135°F), where harmful bacteria multiply rapidly.

Consistent cooling is key, maintaining a safe zone between 33°F and 41°F. Unlike opening walk-in coolers, your ingredients stay consistently chilled right where you need them. The design also means reduced cross-contamination through smart organization. Each ingredient gets its own pan, so ingredients spend far less time at dangerous temperatures.

When you choose NSF-certified models, you're getting equipment that meets strict health department standards. This is about building customer trust and protecting your reputation. For a deeper dive into food safety benefits, check out our guide on Refrigerated Sandwich Prep Table.

What's the difference between a sandwich prep table and a pizza prep table?

While both are refrigerated prep units, their design differs based on the task. The main difference is the cutting board depth and overall workspace design.

Sandwich prep tables feature a more compact cutting board, typically 9-12 inches deep. This provides enough room for slicing and assembly without taking up excessive kitchen space.

Pizza prep tables, on the other hand, need more real estate. Their cutting boards often stretch 18-24 inches deep to accommodate large doughs and pizza peels. They're built for the unique demands of pizza making.

The pan rail configuration also differs. Sandwich stations usually have a continuous line of smaller pans, while pizza tables might have areas for dough or larger bulk containers.

Choose based on your primary menu. If you're making sandwiches, subs, and salads, a sandwich prep table's compact design will serve you better. Learn more about pizza-specific setups in The Secret Sauce Behind Efficient Pizza Prep Stations.

Are these units energy-efficient?

Modern sandwich station coolers are increasingly energy-efficient. Rising energy costs and environmental concerns have pushed manufacturers to create units that consume less power than older models.

Look for ENERGY STAR certification when shopping. These units meet strict EPA standards and can significantly reduce your monthly utility bills.

Many newer models use R290 hydrocarbon refrigerant, which cools more efficiently while being gentler on the environment. Units like the Maxx Cold X-Series and Everest EPBNR2 use this technology.

High-density insulation acts like a good winter coat for your refrigeration system. Better insulation means the compressor works less, using less energy.

Some units feature ECM fan motors, which consume less power while providing stronger, more consistent cooling. The Everest EPBNR2 is a great example, also including smart features like self-maintaining condensate drains that eliminate the need for energy-hungry external heaters.

Yes, energy-efficient models might cost more upfront, but the long-term savings on utilities make them a smart investment.

Conclusion

Your sandwich station cooler isn't just another piece of kitchen equipment – it's the backbone of an efficient, profitable deli operation. Throughout this guide, we've walked through everything from the compact charm of countertop units perfect for cozy cafes to the powerhouse capabilities of full-size mega tops that can handle the busiest lunch rushes.

The journey to finding your perfect unit starts with understanding what really matters. Stainless steel construction isn't just about looking professional – it's about durability that lasts through years of daily service. Digital temperature control keeps your ingredients in that sweet spot between 33-41°F, while NSF certification gives you peace of mind that you're meeting health department standards.

We've explored how the right configuration can transform your workflow. Whether you need the extended pan capacity of a mega top design, the accessibility of drawer storage, or the space-saving benefits of a compact 27-inch unit, there's a sandwich station cooler that fits your specific needs like a glove.

The models we've highlighted – from the high-volume champion True TPP-93 to the budget-friendly Atosa MSF8302 Mega Top – show that quality and reliability come in many forms. Each brings something special to the table, whether it's Beverage-Air's versatility or Maxx Cold's compact efficiency.

This investment pays dividends beyond the initial purchase. Energy-efficient models with ENERGY STAR certification and R290 refrigerants save money month after month. Proper maintenance keeps your unit running smoothly for years, while the right accessories turn a good prep station into a great one.

Your sandwich station cooler becomes the silent hero of your kitchen – keeping ingredients fresh, organizing your workflow, and enabling your team to create consistently delicious food safely and efficiently. It's the difference between scrambling during rush hour and sailing through with confidence.

Ready to transform your deli's efficiency and food safety? Explore our full collection of prep tables and find the perfect partner for your business success!