Cheat Sheet: Best Pizza Wheels & Cutters

Share

Why Every Pizzeria Needs the Right Pizza Wheel

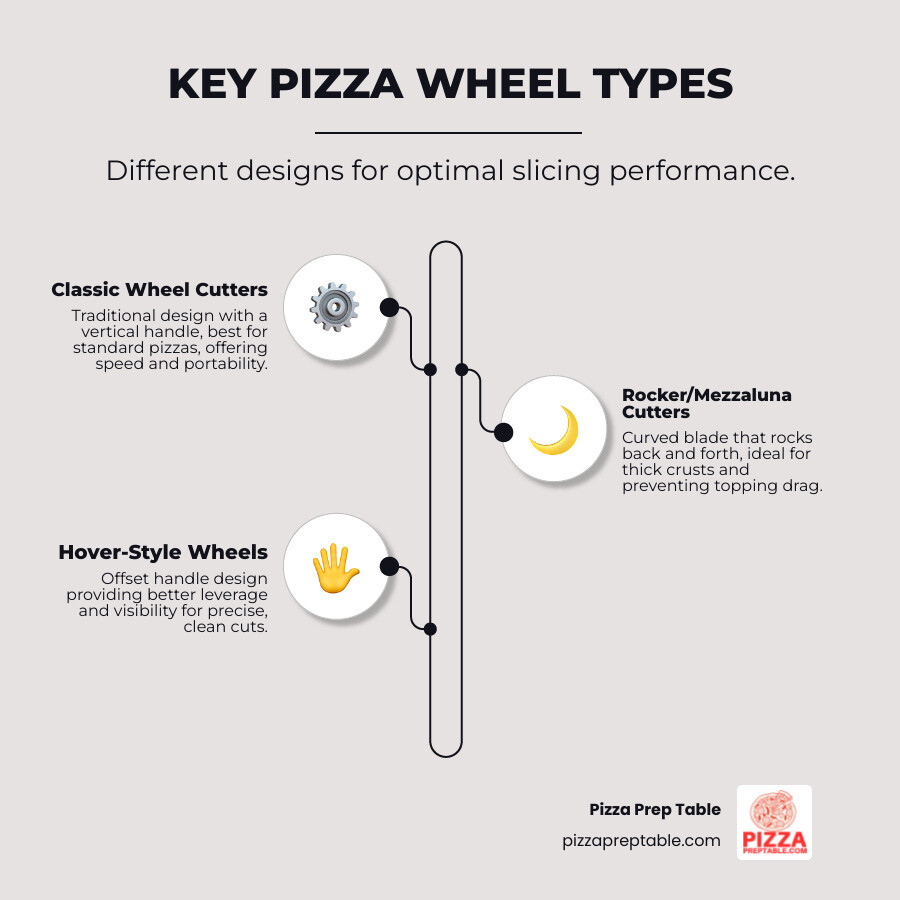

Pizza wheels are specialized rotary cutters (see pizza cutter) designed to slice through pizza crusts and toppings cleanly without dragging cheese or disturbing the presentation. They consist of a sharp circular blade (typically 2.5 to 4 inches in diameter) mounted on a handle, and come in several varieties:

- Classic Wheel Cutters - Traditional design with a vertical handle, best for standard pizzas

- Rocker/Mezzaluna Cutters - Curved blade that rocks back and forth, ideal for thick crusts

- Hover-Style Wheels - Offset handle design that provides better leverage and visibility while cutting

With pizza being one of the most popular foods worldwideAmericans alone consume about 46 slices per yearhaving the right cutting tool isn't just a luxury. It's essential for consistent portioning, professional presentation, and efficient service. The wrong pizza wheel leads to uneven slices, topping drag, and frustrated customers. The right one delivers clean cuts in a single pass, maintains your pizza's visual appeal, and speeds up service during rush hours.

The global pizza market was valued at $134.74 billion in 2022 and continues growing, which means the demand for reliable kitchen tools grows with it. Whether you're outfitting a new pizzeria or upgrading worn equipment, choosing the right pizza wheel affects both your kitchen's efficiency and your customers' satisfaction.

I'm Sean Kearney, and my background in sales and deep appreciation for the foodservice industry has taught me that having the right pizza wheels can make the difference between a smooth service and a frustrating one. I've helped countless restaurant owners find equipment that improves their workflow while staying within budget.

The Anatomy of a Perfect Slice: Types of Pizza Wheels

When it comes to slicing that perfect pie, not all pizza wheels are created equal. Just like there are different types of pizzas, there are different tools designed to conquer them. The right wheel can mean the difference between a clean, professional cut and a messy disaster that leaves cheese dragging across the plate.

Whether you're aiming for that classic New York slice or tackling a hearty Chicago deep dish, understanding your options helps you achieve consistently professional results. A clean cut isn't just about aesthetics—it keeps toppings where they belong and maintains the integrity of the crust. For more on selecting the ideal tool, check out our guide on finding your perfect pizza cutter.

The Classic Wheel

The classic wheel cutter is the tool most of us picture when someone mentions a pizza wheel. It's simple, effective, and has been the go-to choice in pizzerias for decades. A circular blade mounted on a handle, designed for one thing: cutting pizza fast.

What makes the classic wheel so popular? Speed is the biggest advantage. One quick rolling motion across the pizza and you're done. This single-hand operation makes them incredibly efficient during busy service when every second counts. Their compact, portable design means they can be easily stored in a drawer or carried to different stations without taking up valuable counter space.

The rolling action is intuitive—just apply firm pressure and push the wheel across the pizza in one smooth motion. You don't need special training or technique to use one effectively. That's why they're common in pizzerias of all sizes, from neighborhood shops to national chains.

Of course, no tool is perfect. Classic pizza wheels can sometimes cause topping drag, where the blade pushes cheese and other ingredients rather than slicing cleanly through them. This usually happens when the blade gets dull or when you don't apply enough pressure. But with proper maintenance and a sharp blade, these wheels deliver consistent results shift after shift.

Specialty Pizza Wheels

Beyond the standard design, specialty pizza wheels address specific challenges that come with different pizza styles. If you've ever tried cutting a Chicago deep-dish with a standard wheel, you know exactly why these exist.

Larger wheels make all the difference when dealing with thick crust or deep-dish pizzas. A 4-inch diameter blade provides the reach and leverage you need to cut through multiple layers of cheese, toppings, and that substantial crust without crushing the pie. Standard 2.5-inch wheels just don't have the height to handle these hefty creations. If you're serving Chicago-style pizza, investing in a larger wheel isn't optional—it's essential.

Double-bevel wheels take sharpness to the next level. Instead of a single cutting edge, these blades are sharpened on both sides, creating an ultra-sharp point that glides through even the toughest crusts. They're particularly useful for pizzas with thick, chewy crusts or lots of toppings that can bog down a standard blade.

Ergonomic handles might seem like a small detail, but they make a huge difference during long shifts. Some specialty wheels feature offset or "hover-style" handles that reduce wrist strain and provide better visibility while cutting. The Full Circle Slice Pizza Wheel is a great example—its pivoting offset handle gives you increased leverage and lets you see exactly where you're cutting, making precise portioning much easier.

Whether you're slicing thin-crust New York style pizza or hefty deep-dish pies, there's a specialty wheel designed to handle your specific needs. The right tool doesn't just make the job easier—it delivers the professional results your customers expect.

Choosing Your Weapon: A Buyer's Guide to Pizza Wheels

When you're running a pizzeria, choosing the right pizza wheel isn't just about picking something that looks sharp. It's about finding a tool that'll hold up through hundreds of cuts, keep your staff comfortable during the dinner rush, and deliver clean slices every single time. Whether you're outfitting a brand-new shop or replacing worn-out equipment, understanding what makes a great pizza wheel can save you money and headaches down the line.

The blade material, handle design, and safety features all play crucial roles in how well your pizza wheels perform day after day. A cheap cutter might seem like a bargain until it dulls after a week or causes hand fatigue in your staff. On the other hand, investing in quality tools pays dividends in efficiency and consistency. For a broader look at outfitting your entire operation, check out our guide on everything you need to know to buy pizza shop supplies.

Blade Breakdown: Material and Size

The blade is where the magic happens, and getting this part right makes everything else easier. Stainless steel is the gold standard for pizza wheel blades, and you'll rarely see professional-grade cutters made from anything else. It resists rust even in humid kitchens, maintains its edge longer than softer metals, and meets health department standards without breaking a sweat. When you're evaluating pizza wheels, always verify that the blade is high-quality, rust-resistant stainless steel.

Blade diameter matters more than most people realize. While you'll find smaller 2.5-inch wheels out there, a 4-inch diameter blade is generally considered the sweet spot for most pizzerias. That extra surface area means you can cut through an entire pizza in one smooth motion, rather than having to saw back and forth. This is especially important when you're dealing with thick crusts or heavily topped pies. If you're serving New York style pizza with its characteristic thin crust, a larger, sharp blade glides through without tearing the delicate base.

Here's something that often gets overlooked: single versus double bevel blades. While double-beveled edges work fine for general kitchen knives, many experts swear by single-beveled blades for pizza wheels. A single bevel creates ramrod-straight cuts that give you perfectly portioned slices every time. This precision isn't just about aesthetics—it's about giving your customers the consistent experience they expect.

Handle with Care: Ergonomics and Materials

You might think the handle is just something to hold onto, but when your crew is slicing dozens of pizzas during peak hours, handle design becomes critical. The right handle prevents fatigue, gives you better control, and can even make cleaning easier.

| Handle Material | Grip | Durability | Hygiene |

|---|---|---|---|

| Plastic (Polypropylene) | Often textured for a non-slip grip | Good, resistant to impact and chemicals | Dishwasher-safe, non-porous |

| Wood | Natural, comfortable feel, can be warm | Varies, susceptible to moisture and cracking | Requires hand-washing, can be porous |

| Composite (Kraft Paper Resin) | Excellent, often non-slip | High, resistant to heat and water, antibacterial | Dishwasher-safe, non-porous, naturally antibacterial |

| Stainless Steel | Smooth, can be slippery when wet | Very high, rust-resistant | Dishwasher-safe, non-porous |

Traditional handles extend straight from the blade's axle in a vertical orientation. They work fine for basic tasks, but they're not always the most comfortable option for extended use. That's where offset or hover-style handles come into play. The Full Circle Slice Pizza Wheel is a perfect example of this design innovation. The handle sits above the blade rather than behind it, giving you better leverage and a clearer view of exactly where you're cutting. This design also allows for a more natural lateral slicing angle that's easier on your wrist.

Grip comfort isn't something to compromise on. A handle that feels good in your hand makes the difference between smooth, confident cuts and awkward, hesitant ones. Textured surfaces help prevent slipping, while materials like composite resin naturally resist bacteria growth—a nice bonus in any commercial kitchen.

Essential Features for the Best pizza wheels

Once you've got the basics of blade and handle sorted, there are several features that separate ordinary pizza wheels from truly exceptional ones. These details might seem small, but they add up to better performance and safer operation.

Finger guards are non-negotiable in a busy kitchen. A built-in thumb guard protects your hands if your grip slips during an aggressive cut through a stubborn crust. You don't want anyone heading to urgent care because a pizza wheel didn't have basic safety features.

Protective covers might seem like a minor accessory, but they're invaluable for safe storage. When you're reaching into a drawer full of tools during the dinner rush, you don't want to accidentally grab a sharp blade. These covers also keep the edge protected and clean between uses.

Dishwasher-safe design makes life easier, even though hand-washing is often better for maintaining blade sharpness. Many modern pizza wheels can handle commercial dishwashers without issue, which saves precious cleanup time at the end of a long night.

The ability to easily disassemble your pizza wheel is a game-changer for maintenance. If you can unscrew the blade from the handle, you can thoroughly clean every component and sharpen the blade properly. No more mystery gunk hiding in hard-to-reach spots.

Sturdy construction prevents wobbling and bending under pressure. When you're cutting through a thick-crusted pie loaded with toppings, you need a blade that stays true. Look for quality rivets or secure attachment mechanisms—a blade that comes loose mid-slice is dangerous and frustrating.

These features might add a few dollars to the upfront cost, but they pay for themselves in reduced replacement frequency, better safety, and improved performance. When you're choosing pizza wheels for your operation, think long-term value rather than just the sticker price.

Mastering the Slice: Pro Tips for Use and Maintenance

Even the best pizza wheel is only as good as the hand wielding it. I've seen countless pizzeria owners invest in top-quality cutters, only to wonder why they're not getting clean cuts. The secret? It's all about technique and proper care.

A well-maintained pizza wheel isn't just about making perfect cuts; it's about efficiency and safety in our kitchens. When we take care of our tools, they take care of us—and our customers notice the difference. For more techniques on getting the most from your cutting tools, explore our guide on mastering the slice with pizza cutter techniques for your pizza stone.

Technique for a Flawless Cut

Here's something most people don't realize: timing matters as much as the tool itself. After pulling your pizza from the oven, give it a minute or two to rest. I know it's tempting to slice immediately, but that brief pause lets the cheese set slightly. This simple step prevents that frustrating moment when all the toppings slide off in one gooey mass.

When you're ready to cut, confidence is key. Apply firm, even pressure as you roll the pizza wheel across the pizza. Think of it like riding a bike—hesitation creates problems. We want one smooth, decisive motion from center to edge. Multiple passes don't just waste time; they drag toppings around and dull your blade faster.

The single-pass technique separates the pros from the amateurs. Start at the center of your pizza and roll outward to the crust in one continuous motion. Keep your pressure consistent and your movement steady. If you're cutting multiple pizzas during a rush, this technique becomes second nature—and it's noticeably faster.

One more crucial detail: always use a proper cutting surface. Your pizza wheels will thank you, and so will your prep tables. Cutting directly on metal pans dulls blades quickly, while the wrong surface can damage both your tool and your workspace. A dedicated cutting board designed for pizza work makes all the difference. Check out our guide on cutting-edge choices for pizza prep table cutting boards to find the right match for your operation.

Care and Longevity of your pizza wheels

Let's talk about keeping these workhorses in peak condition. While many stainless steel pizza wheels claim to be dishwasher safe, hand-washing is your best bet for longevity. Those harsh dishwasher detergents and high temperatures might be convenient, but they're slowly dulling your blade's edge. A quick hand wash with warm, soapy water takes thirty seconds and can double your blade's lifespan.

Blade sharpness isn't just about ease—it's about food quality. A dull blade drags toppings, tears crust, and makes every cut a struggle. If your pizza wheel has a screw-attachment design that allows disassembly, you can carefully sharpen it yourself using a fine-grit sharpening stone or ceramic rod. Not comfortable sharpening? Professional sharpening services exist for exactly this reason, and they're worth every penny.

High-quality stainless steel resists rust, but it's not invincible. The key to rust prevention is simple: never let your pizza wheel air dry. After washing, dry it immediately with a clean towel. This is especially important in humid climates or during summer months when moisture lingers.

Proper storage protects both your investment and your staff. Those protective covers that come with professional pizza wheels? They're not just packaging—use them. A covered blade stays sharper longer and prevents accidental cuts when someone reaches into a crowded drawer. Store your cutters where the blade won't bang against other utensils, which causes nicks and dull spots.

More Than Just Pizza: Versatile Uses

Here's where pizza wheels really shine in a commercial kitchen. While they're obviously perfect for pizza, we've finded they're secret weapons for all sorts of tasks.

Need to portion dough quickly? Whether you're making pastries, fresh pasta, or breadsticks, a pizza wheel cuts through faster and cleaner than a knife. For quesadillas, it glides through tortillas and melted cheese without the tearing you'd get from a standard blade. During prep work, we've even used them to mince large quantities of herbs—just roll repeatedly over the herbs on your cutting board for a quick, fine chop.

Pastry work becomes easier too. From puff pastry sheets to pie crusts, the rolling motion cuts delicate doughs without the dragging and stretching that happens with knives. And for flatbread sandwiches or wraps, a pizza wheel divides them into portions in seconds—far more efficient than sawing through with a serrated knife.

The versatility means you're getting more value from a single tool. In a busy commercial kitchen where every second and every dollar counts, that matters.

Frequently Asked Questions about Pizza Wheels

We get it—choosing and using the right pizza wheels can raise some questions, especially when you're trying to deliver perfect slices every single time. Let's tackle the most common concerns we hear from pizzeria owners and kitchen managers.

What's the best type of pizza wheel for deep-dish pizza?

When you're facing down a towering Chicago-style deep-dish pizza, your standard pizza wheel might feel a bit outmatched. For more on this regional favorite, check out our guide to pizza in Chicago, IL.

The key is blade diameter. We recommend a pizza wheel with at least a 4-inch blade, though even larger can be beneficial for especially thick pies. That extra reach means you can power through multiple layers of crust, sauce, cheese, and toppings in one confident motion, rather than sawing back and forth.

Beyond size, look for a blade with serious structural integrity. The last thing you want is a blade that bends or wobbles when you're applying the necessary pressure to cut through all those delicious layers. A sturdy, sharp blade prevents crust compression—that frustrating moment when instead of slicing, you're just squashing your beautiful pizza into a dense mess.

Some pizza wheels feature double-bevel blades for extra sharpness, but honestly, a well-maintained single-bevel blade on a large-diameter wheel with good ergonomic leverage will handle deep-dish pizzas beautifully. The real secret is combining size with sharpness and not hesitating when you make your cut.

How do I stop my pizza wheel from dragging the cheese and toppings?

Ah, the dreaded cheese drag. We've all been there—you make your cut, and instead of clean slices, you've got a pizza that looks like it went through a tornado. The good news? This is almost always preventable.

First and foremost, keep that blade sharp. A dull blade doesn't cut; it pushes. If your pizza wheel is pushing ingredients around rather than slicing through them, it's time for sharpening. This single factor makes the biggest difference.

Second, commit to your cut. Use firm, quick pressure and move decisively. Think of it as one smooth, confident motion rather than a tentative back-and-forth. Hesitation is the enemy of clean cuts. The faster and more purposeful your roll, the less time the blade has to grab and drag those toppings.

The one-pass technique is your friend. Each slice should be a single, continuous roll from center to edge. Going over the same cut multiple times multiplies your chances of disturbing the toppings.

Finally, here's a pro tip that many home cooks overlook: let your pizza rest for a minute or two after it comes out of the oven. That brief cooling period allows the cheese to set just enough that it won't be quite as gooey and prone to sticking to your blade. It's a small wait that makes a huge difference in presentation.

Can I sharpen my pizza wheel?

Absolutely, and we encourage it! A sharp pizza wheel is a happy pizza wheel, and keeping that edge maintained extends the life of your tool significantly.

The ease of sharpening depends largely on your pizza wheel's design. Models that allow easy disassembly—typically with a screw mechanism holding the blade to the handle—make the process much more straightforward. You can remove the blade, clean it thoroughly, and sharpen it without wrestling with the entire assembly.

For sharpening at home or in your kitchen, a fine-grit sharpening stone or ceramic sharpening rod works well. The key is maintaining a consistent angle as you run the blade along the sharpening tool. Take your time and work carefully to preserve the blade's original bevel.

If you're running a busy commercial kitchen and don't have time for DIY sharpening, professional sharpening services are worth every penny. They'll restore your blade to like-new condition and ensure it maintains the proper edge geometry. Many restaurant supply companies offer this service, or you can find local knife sharpening services that handle pizza cutters.

Just remember to thoroughly clean the blade after sharpening to remove any metal particles before you use it on food. And if your blade is made from quality stainless steel, it should hold an edge well between sharpenings, especially if you're following proper care and storage practices.

Conclusion: The Right Tool for the Perfect Pie

When you think about it, with over 3 billion pizzas sold every year, that's a whole lot of slicing happening in kitchens around the world. And while we often focus on the perfect dough or the ideal sauce, the truth is that having the right pizza wheel makes all the difference in delivering that final, perfect result to your customers.

Throughout this guide, we've walked through the different types of pizza wheels available—from the tried-and-true classic wheel that's been a pizzeria staple for decades, to modern specialty designs with ergonomic handles and hover-style grips that reduce wrist strain during those long, busy shifts. Each style has its place, whether you're slicing thin-crust New York pies or cutting through the hearty layers of a Chicago deep-dish.

We've also explored what separates a mediocre pizza wheel from a great one. Durable stainless steel blades that hold their edge, comfortable handles that feel good in your hand even after the hundredth slice, and thoughtful safety features like finger guards and protective covers—these aren't just nice-to-haves. They're the details that keep your kitchen running smoothly and your team working safely.

And let's not forget the importance of proper technique and maintenance. A sharp blade, firm pressure, and that confident single-pass cut—these simple practices turn good equipment into great results. Regular cleaning, proper storage, and occasional sharpening keep your pizza wheels performing like new for years to come. Plus, as we've finded, these versatile tools can handle everything from portioning dough to slicing quesadillas, making them even more valuable in a busy kitchen.

At PizzaPrepTable.com, we know that every piece of equipment in your kitchen matters, no matter how small. That's why we're committed to providing professional-grade tools and commercial kitchen equipment to pizzerias and foodservice businesses across major cities like New York City, Los Angeles, and Chicago. Whether you're a small independent shop just starting out or an established pizzeria looking to upgrade, we offer the selection and financing options to help you get exactly what you need.

Investing in quality pizza wheels might seem like a small decision, but it's one that impacts your efficiency, your presentation, and ultimately, your customers' satisfaction every single day. Don't settle for tools that drag toppings or create uneven slices. Equip your kitchen with equipment that performs as well as you do.

Ready to find the perfect cutting tool for your operation? Check out our essential guide to the best pizza cutters for even more insights, and explore our full range of commercial kitchen equipment to outfit your pizzeria for success.