The Ultimate Guide to Commercial Range Hood Installation

Share

Why Proper Commercial Range Hood Installation is Critical for Your Kitchen

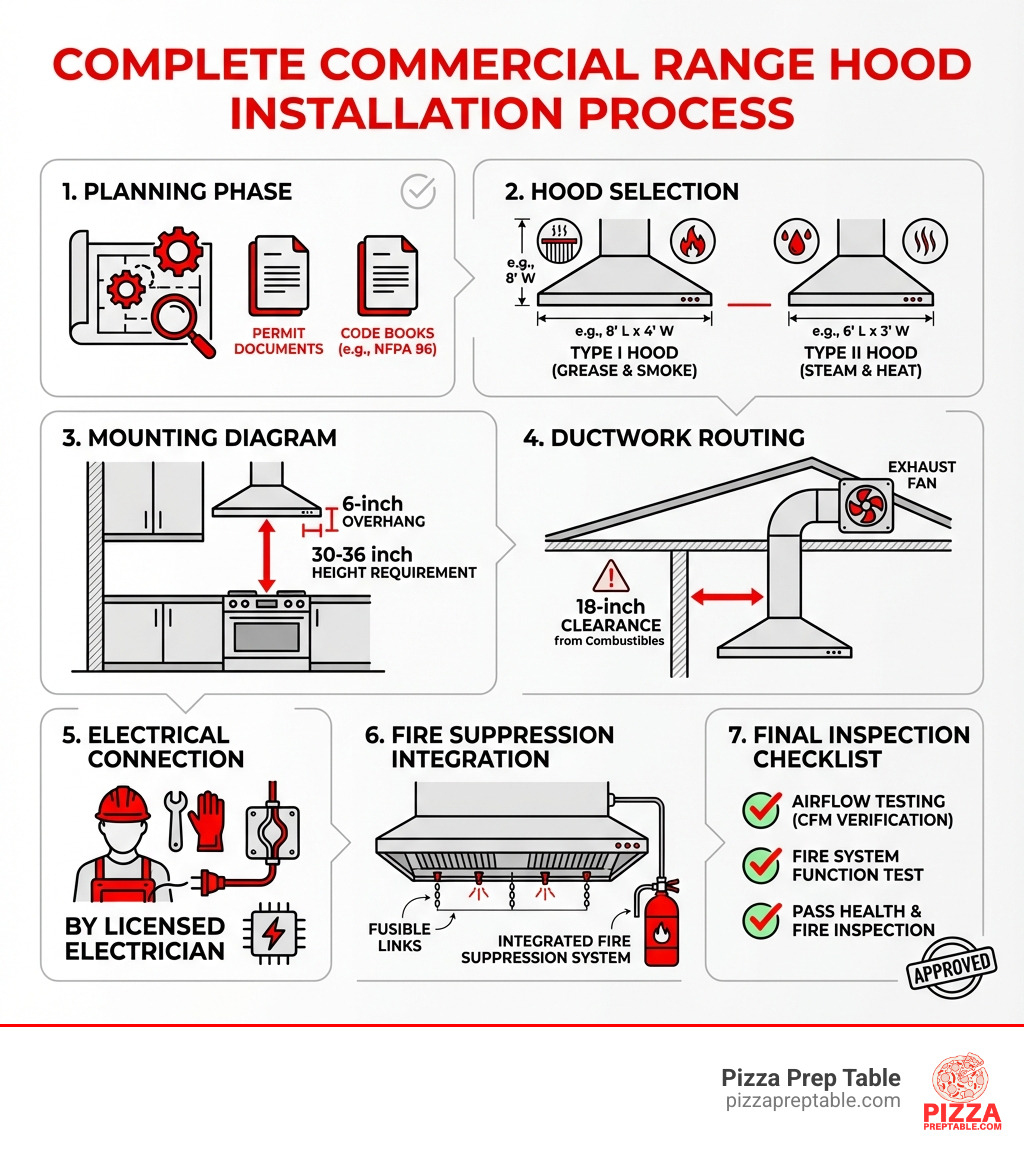

Commercial range hood installation is the process of mounting and activating a ventilation system to remove smoke, grease, heat, and odors from your kitchen. Here's a quick overview:

Key Installation Steps:

- Planning & Permits - Check local codes and get necessary permits.

- Hood Selection - Choose a Type I (grease) or Type II (steam) hood.

- Mounting - Secure the hood 30-36 inches above gas cooktops with a 6-inch overhang.

- Ductwork - Install properly sized ducts, maintaining an 18-inch clearance from combustibles.

- Electrical - Hire a licensed electrician for safe wiring.

- Fire Suppression - Integrate a required fire suppression system for Type I hoods.

- Testing & Inspection - Verify proper operation and pass final inspection.

Average Cost: $750+ (hood + installation), 4-6 hours for professional installation.

For any restaurant, a commercial hood is a fire safety requirement and a health code mandate. Proper installation is essential for protecting your staff, customers, and investment. It removes dangerous grease particles, exhausts unbearable heat, and ensures you pass health inspections, preventing costly fire damage and keeping your insurance valid.

However, commercial hood installation is far more complex than residential models. It involves strict building codes like NFPA 96, fire suppression systems, make-up air units, and professional electrical work. The process requires cutting through walls or roofs, welding ductwork, and integrating multiple systems flawlessly.

I'm Sean Kearney, and I've spent years in the restaurant equipment industry helping owners steer commercial range hood installation. I've seen how a professional setup prevents costly mistakes and keeps kitchens running safely.

Pre-Installation: Planning, Codes, and Hood Selection

Before turning a wrench, meticulous planning is the secret to a successful commercial range hood installation. This stage involves understanding hood types, navigating complex codes, and making crucial sizing decisions.

Understanding Commercial Hood Types and Functions

Commercial hoods are categorized into two main types based on what they exhaust:

- Type I Hoods (Grease Hoods): Mandatory over equipment that produces grease-laden vapors like fryers, charbroilers, and grills. They capture and exhaust heat, smoke, and grease, and are typically made of stainless steel with baffle filters.

- Type II Hoods (Condensate Hoods): Used for appliances producing heat and moisture but little to no grease, such as dishwashers, steam kettles, and some ovens. They remove steam to maintain a comfortable environment.

Hoods also come in various configurations like Wall-Canopy, Island, Backshelf, and Self-Cleaning models to fit your kitchen's layout.

Navigating Codes and Regulations

Commercial kitchens are subject to strict regulations, primarily the NFPA 96 Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations. This standard dictates everything from hood design to ductwork, clearances, and fire suppression.

In cities like New York City, Los Angeles, Chicago, and Houston, you must also adhere to local building codes, fire department rules, and health department requirements. These often adopt or modify national codes like the International Mechanical Code (IMC). A key rule is the 18-inch clearance between the hood, duct, and any combustible materials, though this can sometimes be reduced with approved protection.

Always check with local authorities for specific requirements and obtain all necessary permits before starting work. Failure to comply can lead to fines, shutdowns, and fire hazards. For more details, see our guide on Commercial Kitchen Ventilation Requirements.

Key Sizing and Power Considerations

Getting the right size and power is crucial for effectiveness.

- CFM (Cubic Feet per Minute): This measures the volume of air your hood moves. The required CFM is determined by the type of cooking equipment and local codes, and commercial kitchens require significantly higher ratings than residential ones.

- Hood Height and Overhang: The hood's position impacts its capture efficiency. Commercial codes have specific elevation requirements, and the hood must overhang the cooking surface by at least 6 inches on all open sides to capture fumes.

- Make-Up Air (MUA): As your exhaust hood pulls air out, an MUA system must replace it with fresh, conditioned air. Without it, your kitchen will experience "negative pressure," leading to inefficient hood performance, drafts, and backdrafting of dangerous gases. MUA units are essential for a balanced and safe kitchen environment.

When planning your kitchen, consider how these elements integrate. A well-thought-out plan saves time and money. Explore our insights on Commercial Kitchen Layout Design for more guidance.

The Complete Commercial Range Hood Installation Process

With planning complete, let's dive into the commercial range hood installation process. This is a complex job that demands precision, safety adherence, and professional expertise.

Essential Tools and Materials

A professional installation requires the right equipment.

- Tools: Heavy-duty drill, level, wrenches/sockets, sheet metal shears, caulking gun, measuring tape, stud finder, voltage tester, saws, grinder, welding equipment, and scaffolding or ladders.

- Materials: The commercial range hood, UL-listed ductwork (16-gauge welded steel), threaded rods and mounting brackets, fasteners, high-temperature sealant, exterior wall/roof cap, electrical wiring, and fire suppression components.

Step-by-Step Guide for a Ducted Commercial Range Hood Installation

Installing a ducted commercial hood is a multi-step process that should align with engineer's mechanical drawings.

- Preparation and Inspection: Review plans, confirm the hood location, and ensure the structure can support the weight. Uncrate the hood and inspect for any damage.

- Mark Location and Cut Vents: Use a level to mark the precise mounting points on the ceiling or wall. Carefully cut holes for the exhaust ductwork, avoiding studs, pipes, or wires.

- Assemble and Seal Ductwork: Commercial exhaust ducts must be continuously welded and liquid-tight (typically 16-gauge steel) for fire safety. Assemble sections with minimal bends and weld all joints, including the connection to the hood collar and roof curb.

- Install Exterior Cap: Secure the exterior wall cap or roof curb, ensuring it's properly flashed and sealed to prevent leaks. It should include a backdraft damper.

- Mount the Hood: With assistance, lift the hood into position and secure it to the pre-installed threaded rods or brackets. Ensure it is perfectly level.

- Connect and Finalize: Connect the ductwork to the hood's exhaust collar. Install internal components like lights, baffle filters, and grease cups. Clean the hood with a stainless steel polish.

While residential guides like The Best General Range Hood Installation: Video Guide in 7 Steps can be informative, commercial installations have much stricter requirements.

Step-by-Step Guide for a Ductless Commercial Range Hood Installation

True ductless commercial range hood installation is rare and often not code-compliant for grease-producing cooking, as commercial kitchens almost always require external venting.

However, specialized "ventless" or "recirculating" commercial systems exist for light-duty applications or where ductwork is impossible. These self-contained units use advanced multi-stage filtration (pre-filters, grease filters, activated carbon) to clean and recirculate air. Installation involves mounting the unit, installing the filters, and connecting it to a dedicated electrical circuit. Always verify with local fire and health departments in cities like San Francisco or Dallas if a ventless system is approved for your specific use.

Crucial Safety Precautions During Installation

Safety is paramount during any commercial range hood installation.

- Turn Off Power: Always turn off power at the main breaker box before any electrical work.

- Verify Power is Off: Use a voltage tester to double-check that circuits are dead.

- Wear PPE: Use safety goggles, a dust mask, gloves, and steel-toe boots.

- Use Proper Lifting Techniques: Commercial hoods are heavy. Use lifting equipment or sufficient personnel.

- Secure Ladders: Ensure all ladders and scaffolding are stable and properly secured.

- Maintain Clearances: Always respect the 18-inch clearance rule from combustibles.

For more general safety tips, you can review resources like this guide on renovation safety.

System Integration: Electrical, Fire Suppression, and Final Connections

A commercial range hood is a sophisticated system integrating electrical power, fire safety, and make-up air. Proper integration is non-negotiable for safety and compliance.

How to Properly Connect the Electrical Wiring

Connecting the electrical wiring for a commercial hood is a job for a licensed electrician, as it involves higher power requirements and strict codes in places like Phoenix or Denver.

An electrician will handle:

- Dedicated Circuits: To handle the hood's power demands and prevent overloads.

- Hardwiring: Most hoods are hardwired directly into the building's electrical system for a secure connection.

- Fan and Lights: Connecting power to the exhaust fan and lighting.

- Grounding: Proper grounding is essential to prevent electrical shocks.

- Conduit: All wiring must be run through approved conduit and junction boxes.

A professional ensures all connections are secure and code-compliant, a critical step in your Commercial Kitchen Equipment Checklist.

Integrating the Kitchen Hood Fire Suppression System

For Type I hoods (over grease-producing appliances), an automatic fire suppression system is mandatory. It's your kitchen's frontline defense against grease fires.

How Commercial Kitchen Hood Fire Suppression Systems Work:

These systems detect and extinguish fires almost instantly. Heat-sensitive fusible links placed above cooking surfaces melt during a fire, triggering the system. This automatically releases a chemical extinguishing agent through nozzles aimed at the cooking surfaces and ductwork. Crucially, the system also shuts off the fuel supply (gas or electric) to the cooking equipment to prevent reignition.

Types of Kitchen Hood Fire Suppression Systems:

- Wet Chemical Systems: The most common and effective type for grease fires. They discharge a liquid agent that creates a foam blanket, cooling hot surfaces and smothering the fire.

- Dry Chemical Systems: These use a powdered agent to smother fires but are less common for dedicated grease hood suppression.

Key Components of a Fire Suppression System:

A complete system includes a storage tank for the chemical agent, piping, discharge nozzles, heat-sensitive fusible links, an automatic fuel shut-off, and a manual pull station for staff. Integrating this system during commercial range hood installation is a complex process that must be performed by certified technicians to comply with NFPA 96 and local fire codes in cities like Atlanta or Washington, D.C.

Post-Installation: Maintenance, Cleaning, and Compliance

The installation is done, but the work isn't over. Regular maintenance and cleaning are essential to keep your commercial range hood functioning safely, efficiently, and in compliance with health codes.

Essential Maintenance and Cleaning Tasks

A well-maintained hood system performs better and lasts longer.

- Baffle Filter Cleaning: Clean these grease-trapping filters every 2-4 weeks, or even daily in high-volume kitchens. They can be run through a commercial dishwasher.

- Grease Trap Emptying: Regularly empty the grease collection box to prevent overflow and fire hazards. Learn more in our guide on Cleaning a Grease Trap.

- Fan Inspection: Periodically check the exhaust fan for unusual noises or vibrations and keep the blades clean.

- Duct Cleaning Schedule: The entire exhaust ductwork must be professionally cleaned at regular intervals as specified by NFPA 96 (e.g., quarterly for high-volume cooking) to remove hazardous grease buildup.

- Exterior Surface Wiping: Regularly wipe down the hood's exterior with stainless steel cleaners.

Fire Suppression System Inspection Requirements

Your fire suppression system is a life-saving device that requires rigorous, scheduled inspections.

- Professional Inspections: According to NFPA 96 standards, a certified technician must inspect your fire suppression system bi-annually (every six months). They will check all components, verify the agent's expiration date, and test the fuel shut-off mechanisms.

- Kitchen Staff Visual Checks: Management should conduct monthly visual checks to ensure nozzles are clear and pull stations are accessible.

- Consequences of Neglect: Neglecting inspections can lead to increased fire risk, legal fines, voided insurance policies, and business interruption.

Regular, documented inspections are a key part of any Restaurant Health Inspection Checklist.

Signs of Trouble and Common Repairs

Be aware of these signs of trouble to address issues before they escalate.

- Reduced Airflow: Smoke or steam isn't clearing efficiently. This could mean clogged filters or a malfunctioning fan.

- Unusual Noises: Rattling or grinding sounds from the fan motor indicate mechanical wear.

- Dripping Grease: Indicates oversaturated filters or a blockage in the collection system.

- Fan Motor Failure: The fan won't turn on or runs intermittently.

- Excessive Heat or Odors: The exhaust system isn't performing adequately.

- Electrical Problems: Flickering lights or tripped breakers require immediate attention.

While you can clean filters yourself, call a professional service for fan, motor, or electrical problems.

Frequently Asked Questions about Commercial Hoods

Can I perform a commercial range hood installation myself?

We strongly advise against a DIY commercial range hood installation. The complexity, regulations, and safety risks are significantly higher than for residential units.

Professional installation is crucial because of:

- Strict Codes: Professionals understand NFPA 96, local building codes, and health regulations.

- Specialized Work: The job requires heavy equipment, specific mounting, and often welding for ductwork.

- Fire Suppression: Type I hoods require certified technicians to install and integrate fire suppression systems.

- Electrical & MUA: Licensed electricians must handle the high-power requirements, and experts are needed to balance the make-up air system.

- Insurance and Liability: Improper installation can void your insurance and create huge liability.

The peace of mind and compliance from a professional installation far outweigh any potential DIY cost savings.

How much does a commercial range hood installation cost?

The cost for a commercial range hood installation is much higher than residential. While a home installation might average around $750 (per Forbes), a complete commercial system is a larger investment.

Key cost factors include:

- Hood Type and Size: Larger Type I hoods cost more than smaller Type II hoods.

- Ductwork Complexity: The length and route of the ductwork significantly impact price.

- Make-Up Air & Fire Suppression: These required systems are major additional expenses.

- Labor and Permits: Costs for licensed technicians and local permits add up.

A complete commercial range hood system installation can range from $5,000 to $20,000 or more, depending on your kitchen's complexity. Always get detailed quotes from reputable commercial ventilation specialists.

What are high-efficiency ecology filters?

High-efficiency ecology filters are advanced, multi-stage filtration systems that go beyond standard baffle filters to improve air purity and maximize grease extraction.

Their benefits include:

- Superior Grease Extraction: They capture more airborne grease, reducing ductwork buildup and fire risk.

- Improved Air Purity: They trap a wider range of particulates, which is crucial in dense urban areas.

- Odor Control: Many systems include activated carbon filters that absorb cooking odors, preventing them from becoming a public nuisance.

- Energy Savings: By keeping ductwork cleaner, they can improve airflow efficiency and lower energy use.

These systems often use a combination of filters, such as pleated pre-filters, grease-resistant bag filters, high-temperature ASHRAE filters, and activated carbon filters, to achieve superior performance. They are a smart investment for kitchens needing to meet strict air quality and environmental regulations.

Conclusion

A successful commercial range hood installation is a critical investment in the safety, efficiency, and longevity of your restaurant. From understanding hood types to navigating NFPA 96 codes and integrating fire suppression systems, every step demands professional expertise.

We've covered the detailed planning, installation steps, safety precautions, and the vital role of ongoing maintenance. While the costs are significant, the benefits—a clean, safe, and compliant kitchen—are immeasurable. A properly installed and maintained hood system is the backbone of any successful commercial kitchen.

At Pizza Prep Table, we understand the demands of restaurant operations in cities like Los Angeles, Chicago, and Houston. Don't leave this critical component to chance; partner with certified professionals to ensure your kitchen operates safely and smoothly for years to come.

When you're ready to equip your kitchen, we're here to help. Explore our full range of commercial kitchen equipment and see how Pizza Prep Table can support your culinary journey.