Prep Fridges 101 – Cool Tips for Cooler Kitchens

Share

What is a Prep Fridge? The Unsung Hero of Commercial Kitchens

A prep fridge is a specialized commercial refrigeration unit that combines cold storage with an accessible food preparation workspace. These culinary command centers feature refrigerated ingredient wells on top and cold storage compartments below, allowing chefs to assemble dishes quickly while keeping all components at safe temperatures.

Quick Overview: What You Need to Know About Prep Fridges

- Purpose: Streamline food prep by keeping ingredients cold and within arm's reach.

- Types: Pizza prep tables (raised ingredient rails) vs. sandwich prep tables (recessed wells).

- Key Features: Refrigerated wells, cutting boards, undercounter storage.

- Benefits: Faster service, better food safety, improved workflow efficiency.

- Ideal For: Pizzerias, sandwich shops, delis, fast-casual restaurants, food trucks.

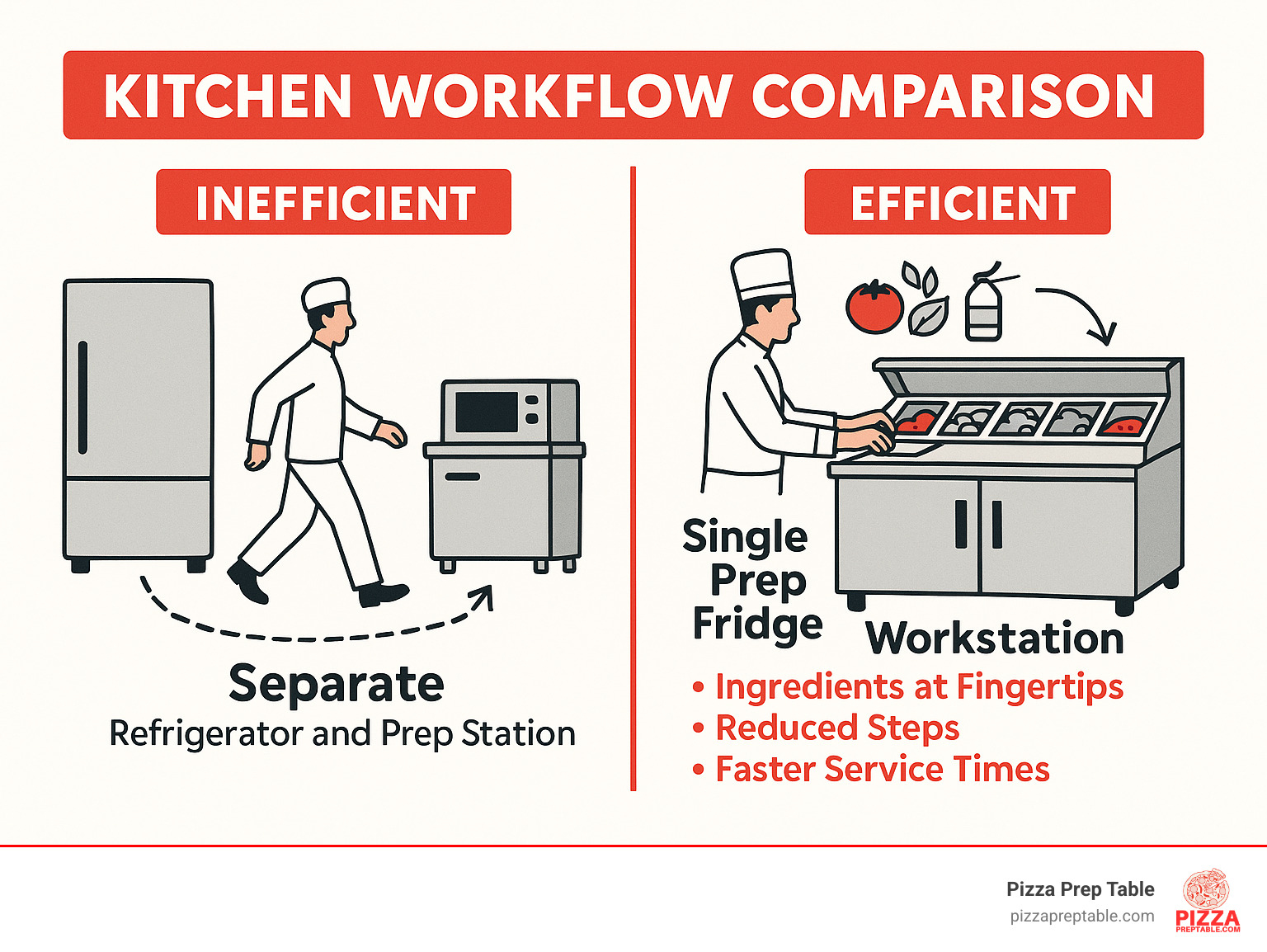

Research shows that refrigerated prep tables are perfect for assembling sandwiches, salads, burritos, and pizzas. These units solve the common problem of inefficient kitchen workflow by eliminating the need to constantly walk between separate refrigeration units and prep areas.

The primary purpose of a prep fridge is to keep fresh ingredients easily within reach while maintaining proper food safety temperatures. Instead of storing ingredients in a walk-in cooler across the kitchen, everything you need stays right at your fingertips. This integrated design means faster ticket times, happier customers, and less food waste from temperature abuse.

A prep fridge is more than just a piece of equipment; it's an investment in efficiency, safety, and the profitability of your kitchen. By creating a self-contained workstation, it allows your team to work smarter, not harder, turning potential chaos into a smooth, streamlined operation.

Who Benefits from a Prep Fridge?

The versatility of a prep fridge means a wide array of food service establishments can reap its benefits. If your business involves assembling fresh ingredients to order, you're a prime candidate.

Here's a breakdown of who stands to gain the most:

- Pizzerias: The pizza prep table shines here, with a deeper cutting board and raised pan rail designed to handle large pizza doughs and an extensive array of toppings.

- Sandwich Shops: A sandwich prep table with its recessed pan well keeps all meats, cheeses, and toppings neatly organized and chilled for rapid, fresh sandwich assembly.

- Delis: Similar to sandwich shops, delis benefit from a dedicated station for slicing and assembling sandwiches or salads, which translates directly into faster customer service.

- Fast-Casual Restaurants: For customizable bowls, burritos, or salads, a prep fridge allows for a smooth assembly line, which is critical for maintaining speed during peak periods.

- Food Trucks: In a tight space, a compact prep fridge offers maximum utility in a minimal footprint, combining essential refrigeration and prep space.

- Salad Bars: A prep fridge is ideal for displaying and keeping greens, toppings, and dressings fresh, ensuring both visual appeal and food safety.

- Burrito Shops: These operations thrive on quick assembly, and a prep fridge keeps all fillings—from rice and beans to proteins and salsas—chilled and ready to roll.

In short, if your business relies on quick, fresh, and safe ingredient assembly, a prep fridge is a fundamental piece of equipment that will significantly improve your operational efficiency and food safety standards.

Types of Prep Fridges: Pizza Prep Tables vs. Sandwich/Salad Stations

While all prep fridges combine cold storage with a workspace, they are often specialized for different menus. The two main types are Pizza Prep Tables and Sandwich/Salad Prep Tables. Understanding their key differences is crucial for choosing the right fit for your kitchen.

Pizza Prep Tables

If you're crafting pizzas, a pizza prep table is your kitchen's best friend. These units are specifically built to handle the unique demands of pizza creation.

A key feature is the deeper cutting board, often 19 inches or more. This generous surface provides ample room to stretch large pizza doughs, add toppings, and maneuver them without making a mess, keeping your workstation clean and your workflow smooth.

Another defining feature is the raised pan rail. This design lifts your ingredient pans slightly above the counter, often at an angle, making it incredibly easy to scoop and sprinkle toppings, especially when a large pizza dough is on the board. This setup speeds up assembly during busy rushes.

The refrigerated section below the rail is designed for standard food pans, ensuring all toppings stay consistently chilled. Beneath that, ample refrigerated cabinet space holds backup ingredients, dough balls, or extra sauce. A quality pizza prep table can dramatically boost speed and efficiency in any pizzeria. Want to learn more? Check out our guide on Slice And Dice In Style Your Guide To Pizza Prep Chillers.

Sandwich & Salad Prep Tables

For kitchens focused on custom sandwiches, vibrant salads, or burritos, the sandwich & salad prep table is the go-to unit. These are designed for the quick, precise assembly of various fresh ingredients.

The most noticeable difference is the standard depth cutting board and a recessed pan well. The shallower cutting board is perfect for assembling individual sandwiches or salads without taking up excess space, facilitating a smooth, linear workflow.

The recessed pan well is a game-changer for these operations. Ingredient pans are nestled down into the unit, often sitting flush with the work surface. This keeps sliced meats, cheeses, and chopped vegetables neatly contained and easy to access. Many models also include a flat insulated lid to cover the pan well when not in use. This lid helps maintain consistent temperatures, saves energy, and provides an extra flat surface for other tasks. These tables are essential for fast-casual spots, delis, and salad bars where speed, freshness, and customization are key. For a deeper dive, our guide on A guide to Sandwich Prep Table Refrigerators offers more valuable insights.

Key Features and Technology for Peak Performance

When you invest in a prep fridge, you're getting a unit packed with smart engineering designed to keep your kitchen running smoothly and your food safe. Understanding these key features will help you appreciate what makes these workstations so essential.

Refrigerated Wells and Pan Rails

The refrigerated wells are where the magic happens, holding food pans (typically Gastronorm pans in sizes like 1/3 or 1/6) to organize your ingredients. These wells use a forced-air refrigeration system that actively circulates chilled air, ensuring every ingredient in the pan stays consistently and safely cold. Consistent cooling is vital for food safety, which is why quality units have NSF-7 compliance. This certification ensures the unit meets strict public health standards for food contact and easy cleaning. For more insights on maximizing your topping station, check out Prep Like A Pizza Pro With These Topping Stations.

Cutting Boards and Work Surfaces

The cutting board is the command center of your prep fridge. Most units feature boards made from durable polyethylene material, which is tough yet gentle on knife blades. NSF-certified cutting boards are non-negotiable, as they are non-porous and won't harbor bacteria. Most are also removable for cleaning, allowing for thorough sanitization. The depth variations between pizza and sandwich tables are purposeful: a deeper board gives pizza makers room to work, while a standard depth is more efficient for assembling smaller items.

Refrigerated Storage Base

Below the work surface, the undercounter cabinet provides essential backup storage. This refrigerated base keeps extra ingredients, pre-prepped items, and bulk supplies organized and within arm's reach. You can typically choose between doors vs. drawers. Doors offer open access for larger items with adjustable shelving, while drawers provide organized compartments for finding specific ingredients quickly. This integrated storage makes your prep fridge a complete, self-contained workstation. If you're curious about other undercounter options, see our guide to Explore Undercounter Refrigerator With Glass Door options.

Food Safety and Temperature Control

Food safety is paramount, and a prep fridge is your first line of defense against the temperature "danger zone" (40°F to 140°F), where bacteria multiply rapidly. Modern units feature digital thermostats for precise temperature management and temperature alarms that alert staff if conditions become unsafe. Advanced airflow systems create a curtain of cool air over the ingredient pans while chilling them from below, preventing the top layers from warming up. Maintaining the food safety "danger zone" below 40°F is critical. According to FoodSafety.gov temperature guidelines, perishables left above 40°F for over two hours must be discarded. A quality prep fridge prevents this costly waste and protects your customers.

The Ultimate Guide to Choosing Your Perfect Prep Fridge

Picking the right prep fridge is a crucial investment that impacts daily operations, team efficiency, and your bottom line. We're here to guide you through the most important considerations to find your perfect match.

Sizing Up Your Prep Fridge: Capacity and Dimensions

Size is critical, both for capacity and kitchen layout. Carefully measure your available floor space, ensuring enough clearance for airflow, maintenance, and staff movement. The unit's doors and drawers must be able to open fully. Your menu complexity and sales volume also dictate the size you'll need. A wider variety of toppings or higher output requires more pan space and undercounter storage to minimize restocking during peak hours.

Prep fridges come in various widths, from compact two-door units to large three- or four-door models. We offer popular sizes like the 67 Inch Pizza Prep Table and the larger 93 Inch Pizza Prep Table. The number of doors or drawers affects organization and access, so choose a size that fits your space and workflow perfectly.

Energy Efficiency and Environmental Impact

Since your prep fridge runs 24/7, energy efficiency is key for managing utility costs and reducing your environmental footprint. Look for models that are ENERGY STAR certified, as they meet strict energy-saving standards. Another major advancement is the use of natural refrigerants like R290 (propane). Brands like Migali, for example, use R290 to achieve up to 40% in energy savings compared to older refrigerants. R290 is non-toxic and has a very low Global Warming Potential (GWP), making it an environmentally friendly choice. Investing in an energy-efficient model is a smart business decision that pays off in the long run.

Top Brands and Budgeting

In commercial equipment, a brand's reputation often signifies quality, durability, and reliable performance. Leading names in the prep fridge world include Atosa, known for great value; Dukers, popular for its tough build and efficiency (explore Top Dukers Pizza Prep Tables To Keep Your Dough Cool And Your Customers Happy); True, a long-time leader in premium quality; and Kelvinator, offering reliable solutions.

While the upfront price is important, always consider the total cost of ownership, including energy consumption and potential maintenance. A cheaper unit may cost more over its lifetime.

We know new equipment is a significant expense. At PizzaPrepTable.com, we offer various financing options to help businesses of all sizes. A popular choice is the 'Rent–Try–Buy' program, which lets you use equipment with manageable weekly payments before committing to a purchase. A significant portion of rental payments can often be applied to the purchase price, offering flexibility to upgrade or return the equipment. This model lowers the initial risk and helps you find the perfect fit for your growing business.

Installation, Maintenance, and Warranty Essentials

Getting a high-quality prep fridge is the first step. To maximize your investment and ensure years of reliable service, proper installation, maintenance, and understanding your warranty are crucial.

Installation Best Practices

Professional installation is non-negotiable for commercial refrigeration. Your prep fridge absolutely must be installed by a licensed, commercial installer to ensure safety, efficiency, and to avoid voiding the manufacturer's warranty. Manufacturers are very clear that improper setup nullifies this valuable protection.

A professional will ensure:

- Proper Clearance: Refrigeration units release heat and need adequate space for airflow around the condenser coils. Without it, the unit can overheat, reducing efficiency and shortening its lifespan.

- Ventilation: The kitchen's ventilation must accommodate the heat generated by the unit.

- Leveling: A perfectly level unit ensures doors seal properly, drainage works efficiently, and internal components operate smoothly.

- Dedicated Power Supply: Commercial equipment often requires a dedicated circuit to prevent power surges that could damage the unit.

Professional installation guarantees your prep fridge starts off operating safely and efficiently.

Routine Maintenance for Your Prep Fridge

Regular care keeps your prep fridge in top form, preventing high energy bills and costly breakdowns. A little TLC goes a long way.

Here are essential maintenance tasks:

- Cleaning Condenser Coils: This is the most important task. The coils release heat, but they collect dust and grease, which acts as an insulator. This forces the compressor to work harder, increasing energy use. Clean them monthly with a brush or vacuum.

- Checking Gaskets: Inspect door gaskets for cracks or tears. A poor seal lets cold air escape. Use the "dollar bill test": if you can easily pull a bill out from a closed door, the gasket may need replacing.

- Cleaning Cutting Boards: Sanitize the removable cutting board regularly throughout the day with food-safe cleaners to prevent bacterial buildup and cross-contamination.

- Sanitizing Wells: Clean and sanitize the refrigerated wells daily to remove spills and debris, maintaining a hygienic environment for your ingredients.

Regular maintenance protects your prep fridge's integrity and extends its life.

Warranty and Replacement Parts

Understand the manufacturer warranty terms before you buy. Warranties typically cover defects for a specific period (often 1-5 years for parts and labor), but actions like improper installation or unauthorized repairs can void the warranty. Keep your purchase documents in a safe place.

Even with great care, parts can wear out. Knowing how to source replacement components quickly is key to minimizing downtime. At PizzaPrepTable.com, we help customers find reliable parts for their equipment. Whether it's a compressor or a cutting board, access to genuine parts gets your prep fridge back to work quickly. For more information, our guide Dont Lose Your Cool Where To Find Pizza Prep Table Parts is an excellent resource.

A well-maintained prep fridge is a long-lasting one, and knowing your warranty options provides peace of mind.

Conclusion: Upgrade Your Kitchen, Lift Your Service

A prep fridge is more than just equipment; it's a strategic investment in your kitchen's efficiency, food safety, and profitability. It is the unsung hero that can transform your commercial kitchen's operations.

By centralizing fresh ingredients, a quality prep fridge eliminates wasted steps, reduces staff strain, and dramatically speeds up service. This leads directly to higher customer satisfaction through faster, fresher meals. Critically, it also champions food safety. By maintaining precise temperatures, it keeps ingredients safely out of the "danger zone" (below 40°F), protecting your customers and your reputation.

Choosing the right prep fridge—considering size, type, and brand—is a decision that pays dividends. When you factor in energy efficiency and commit to proper maintenance, your unit becomes a reliable workhorse that delivers smoother operations and less waste for years to come.

Here at PizzaPrepTable.com, we're passionate about empowering commercial kitchens to succeed. We understand the unique demands of foodservice businesses, from pizzerias in Dallas and Atlanta to busy operations in Philadelphia and Boston. Our goal is to help you steer the options and find the perfect prep fridge that fits your needs and budget.

Ready to give your kitchen the upgrade it deserves and lift your service to the next level? Explore our complete collection of pizza prep tables to find the perfect fit for your business. Let's work together to cool down your kitchen and heat up your profits!