Slice, Dice, and Chill: Prep Coolers You Need Right Now

Share

What Are Prep Coolers and Why Are They a Kitchen Essential?

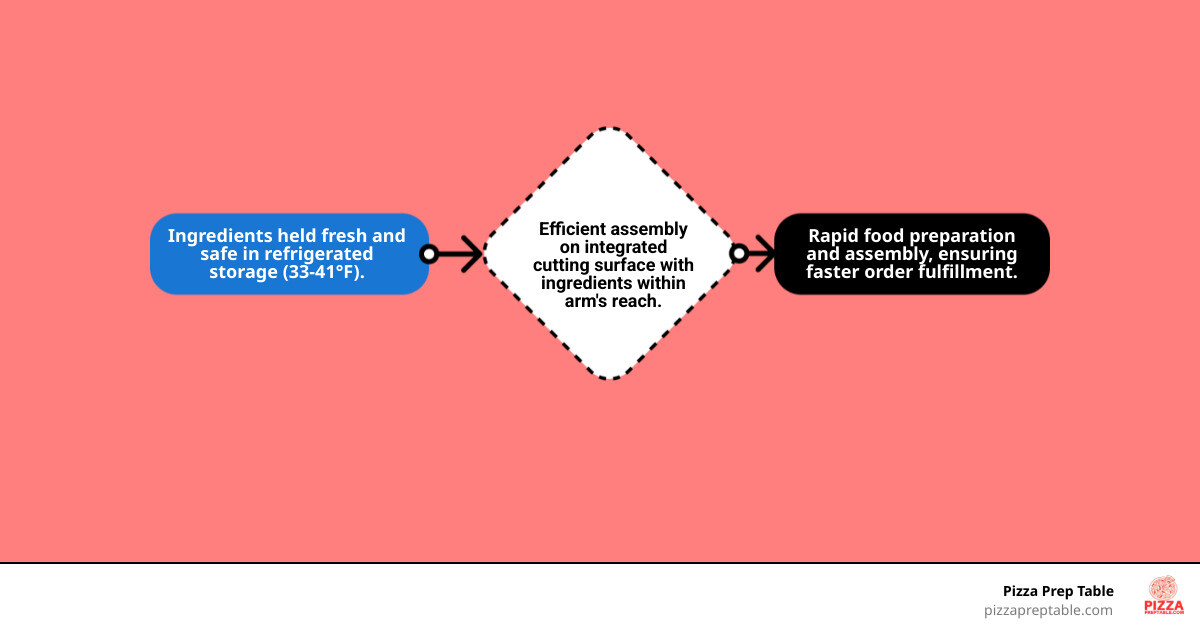

Prep coolers are refrigerated workstations that combine cold storage with a prep surface, keeping ingredients fresh and accessible during food assembly. They are essential for commercial kitchens for several key reasons:

- Temperature Control: Maintain a food-safe range of 33°F to 41°F.

- Workflow Efficiency: Ingredients are stored directly below the cutting surface, speeding up prep time.

- Space Optimization: Combines refrigeration and prep space into a single unit.

- Food Safety: Organized storage helps prevent cross-contamination.

Common types include Pizza Prep Tables with raised rails for toppings, Sandwich/Salad Prep Tables with recessed wells, and Mega Top Models for extra pan capacity.

These units are ideal for pizzerias, delis, cafes, and any kitchen that needs fast, efficient assembly while maintaining proper food temperatures. The right prep table can transform a chaotic kitchen into a well-oiled machine, making it one of the most impactful investments for improving both efficiency and food safety.

The Winning Recipe: Key Benefits of a Refrigerated Prep Station

Prep coolers are the secret weapon that transforms chaotic kitchens into smooth-running operations. The primary benefits include:

- Increased Efficiency: With ingredients stored directly above and below the cutting board, staff eliminate time-wasting trips to the walk-in cooler. This dramatically speeds up service during peak hours.

- Improved Food Safety: These units maintain the critical temperature range of 33°F to 41°F, keeping ingredients in the food-safe zone and preventing bacterial growth.

- Improved Ingredient Freshness & Reduced Waste: Consistent chilling keeps produce crisp and proteins safe, improving quality and reducing spoilage. This means less food waste and more money saved.

- Better Organization & Accessibility: Designated spots for every ingredient create an organized, efficient prep station. Staff can work faster, maintain cleanliness, and focus on food quality instead of hunting for supplies.

For deeper insights into maximizing your prep station's potential, check out the secret sauce behind efficient pizza prep stations. And when it comes to food safety standards, understanding NSF food safety standards is crucial for any commercial kitchen.

Essential Features for High-Performance Prep Coolers

When investing in a prep cooler, look for these high-performance features:

- Stainless Steel Construction: Essential for durability, corrosion resistance, and easy cleaning in a busy kitchen.

- Durable Compressors: The heart of the unit, commercial-grade compressors ensure reliable cooling even during peak hours.

- Digital Temperature Controls: Provide precise temperature management for optimal food safety, eliminating the guesswork of analog dials.

- Integrated Cutting Board: A stable, sanitary, and easy-to-clean work surface is crucial for heavy use.

- Standardized Food Pans: Using standard sizes like 1/6 pans simplifies handling, cleaning, and replacement.

- Self-Closing Doors: A key feature for busy kitchens, they prevent temperature loss and often include a stay-open feature for easy loading.

- Adjustable Shelves: Offer flexible storage in the refrigerated base to accommodate various container sizes.

- Ease of Cleaning: Look for smooth surfaces and removable components to make daily sanitation simple and effective.

For more guidance on choosing the right commercial refrigeration, our commercial fridge shopping guide covers everything you need to know.

Keeping Ingredients Fresh and Safe

Prep coolers are designed to keep ingredients safe and delicious. Key safety aspects include:

- Temperature Accuracy: Digital controllers maintain the crucial food-safe zone of 33°F to 41°F, which is essential for preventing bacterial growth.

- Cross-Contamination Prevention: Separate compartments and pans create natural barriers between different ingredients, like raw proteins and fresh vegetables.

- Smart Organization: A well-organized station is a food safety strategy, helping staff manage inventory and reduce waste.

- NSF and UL Certification: These certifications guarantee the equipment meets strict public health, safety, and electrical standards, which is essential for regulatory compliance.

For specialized applications, consider exploring our guide to refrigerated chef bases, which offer similar benefits with different configurations.

Pizza vs. Sandwich Tables: What's the Difference?

When you're shopping for prep coolers, you'll quickly find that not all tables are created equal. While both pizza and sandwich prep tables share the same basic mission – keeping ingredients chilled and within arm's reach – they're designed with very different workflows in mind.

The main difference comes down to how the ingredients are positioned relative to your work surface. Pizza prep tables feature a raised ingredient rail that lifts your toppings above the cutting board, while sandwich prep tables use recessed wells that sit flush with or slightly below the worktop. This might seem like a small detail, but it makes a huge difference in how efficiently you can work.

Here's how these two types of prep coolers stack up against each other:

| Feature | Pizza Prep Tables | Sandwich/Salad Prep Tables |

|---|---|---|

| Ingredient Rail | Raised above the cutting board (often with a lid) | Recessed into the worktop |

| Cutting Board | Deeper, wider, often extends across the entire width | Standard depth, often integrated into the worktop |

| Typical Use | Assembling pizzas, calzones, large baked goods | Crafting sandwiches, subs, salads, wraps, burritos |

| Pan Compatibility | Often accommodates larger pans (e.g., 1/3, 1/2 size) | Typically uses smaller pans (e.g., 1/6, 1/9 size) |

| Ergonomics | Ingredients lifted for quick access during topping | Ingredients flush with work surface for easy scooping/spreading |

| Storage Below | Refrigerated storage for dough, sauce, cheese blocks | Refrigerated storage for bulk meats, cheeses, vegetables |

The choice between these styles isn't just about preference – it's about matching your equipment to your menu and workflow. A pizzeria trying to use a sandwich table would find their staff constantly reaching down into wells, slowing down service. Meanwhile, a deli using a pizza table would struggle with the raised rails getting in the way of sandwich assembly.

The Perfect Slice: Pizza Prep Tables

If you're running a pizzeria, a dedicated pizza prep table is one of the smartest investments you can make. These prep coolers are purpose-built for the unique demands of pizza making, from stretching dough to creating those perfect topping combinations that keep customers coming back.

The raised ingredient rail is the star of the show here. Instead of making your pizza makers bend and reach into wells, the toppings are lifted up where they can easily grab them. This means faster assembly times and less strain on your staff during those busy Friday night rushes. The rail often comes with a protective lid to keep ingredients fresh between orders.

The cutting board on pizza prep tables is noticeably larger and deeper than what you'll find on sandwich tables. This generous workspace gives your team plenty of room to stretch dough, spread sauce evenly, and arrange toppings without feeling cramped. When you're working with 16-inch pizzas or multiple smaller pies at once, this extra space becomes invaluable.

Below the prep area, you'll find refrigerated storage that's perfect for pizza dough balls, large containers of sauce, and blocks of cheese waiting to be shredded. This setup means fewer trips to the walk-in cooler, keeping your pizza line moving smoothly even during peak hours.

Your typical pizza prep table will hold all the essentials: marinara and white sauces, mozzarella and specialty cheeses, pepperoni and sausage, mushrooms and bell peppers, onions and olives, plus fresh basil and other herbs. Everything stays at the perfect temperature and within easy reach.

For more insights into how these specialized units can transform your pizza operation, check out our guide to pizza prep chillers.

The Ultimate Build: Sandwich & Salad Prep Tables

Delis, cafes, and sandwich shops have their own unique needs, and that's where sandwich and salad prep coolers really shine. These tables are designed for speed and versatility, helping you build everything from classic subs to gourmet salads with remarkable efficiency.

The recessed wells are the key feature here. Unlike the raised rails on pizza tables, these ingredient compartments sit flush with your work surface, making it easy to scoop, spread, and layer ingredients. Whether you're building a towering club sandwich or tossing a fresh Caesar salad, this design keeps everything flowing smoothly.

The integrated cutting board provides a seamless work surface for slicing meats and cheeses, chopping vegetables, and assembling your creations. There's no awkward reaching over raised rails – just a clean, efficient workspace that adapts to whatever you're making.

These versatile prep coolers excel at storing the wide variety of ingredients that make great sandwiches and salads possible. Your cold cuts like turkey, ham, and roast beef stay perfectly chilled, while sliced cheeses remain fresh and ready to use. Fresh vegetables like lettuce, tomatoes, and onions maintain their crispness, and spreads and dressings stay at the ideal consistency for easy application.

The refrigerated storage below keeps your bulk ingredients well-stocked, so you can quickly refill pans throughout the day. This setup ensures you're always ready for the lunch rush, whether customers want a simple turkey sandwich or a loaded chef's salad.

For establishments focused on made-to-order items, these tables are absolutely essential. They keep ingredients at safe temperatures while making assembly fast and intuitive. To learn more about how these units can keep your customers happy with fresh, delicious food, visit our guide on sandwich refrigerators that keep ingredients fresh.

Our Top Picks: Choosing the Right Commercial Prep Coolers for Your Kitchen

Finding the perfect prep cooler for your kitchen is like choosing the right tool for a craftsman - it needs to fit your space, match your workflow, and handle your volume without breaking a sweat. The good news? With some smart planning, you can find exactly what you need.

Sizing is your first consideration, and it's more important than you might think. Prep coolers range from compact 27-inch units that fit snugly in cozy cafes to massive 93-inch workhorses built for pizza factories. Think about your kitchen's footprint and your daily volume. A busy pizzeria needs room to stretch multiple doughs simultaneously, while a neighborhood deli might thrive with a more modest setup.

Configuration is where things get interesting. You'll need to decide between doors and drawers for your storage - doors give you bulk access, while drawers keep things organized and easy to grab in tight spaces. Then there's the mega top versus standard question. Mega top prep coolers are like having a bigger toolbox - they hold more ingredient pans and give you room to work with larger portions. Standard tops work beautifully for simpler operations.

Capacity ties directly into your menu complexity. How many different toppings, meats, or vegetables do you need within arm's reach? The beauty of modern prep coolers is their flexibility - you can often adjust the refrigerated section layout to accommodate different pan sizes as your menu evolves.

Don't overlook brand reputation when making your choice. Companies like True Refrigeration, Atosa, Ikon, EFI, and Dukers have earned their stripes in commercial kitchens nationwide. These brands stand behind their products with solid warranties and reliable customer support - something you'll appreciate when you're in the middle of a dinner rush.

If you're leaning toward Atosa, you can Explore Atosa Pizza Prep Tables for detailed insights. For those considering a 2-door setup, See our review of 2-door pizza prep fridges to see what might work best.

Top-Rated Prep Coolers for High-Volume Pizzerias

High-volume pizzerias are different beasts entirely. When you're cranking out hundreds of pies during peak hours, every second counts, and your prep cooler needs to be your reliable partner, not a bottleneck.

The magic starts with an extra-wide work surface - we're talking 72 inches or even 93 inches of pure workspace. This isn't just about showing off; it's about creating multiple prep stations so your team can work simultaneously without bumping elbows. Picture three pizzaiolos stretching dough, saucing, and topping different orders at the same time - that's the efficiency you're after.

Mega top design becomes essential at this volume. The expanded top rail isn't just convenient; it's a game-changer that holds more ingredient pans and reduces those workflow-killing refill trips during your busiest hours. You'll want high pan capacity with room for larger 1/3 or 1/2 size pans for your heavy hitters like cheese and sauce, plus smaller pans for specialty toppings.

Your refrigeration system needs to be a powerhouse - a robust, heavy-duty compressor that maintains consistent temperatures even when doors are constantly opening and closing. Durable stainless steel construction isn't optional at this level; it's your insurance policy against the wear and tear of continuous use.

The storage below should be equally impressive, with multiple doors (like 3-door configurations) providing better organization and temperature stability. Adjustable shelves let you customize the space for bulk dough, prepped ingredients, and backup supplies.

True Refrigeration and Dukers are the heavy hitters in this category. True Refrigeration has built a reputation on consistent performance under pressure, while Dukers offers robust options that can handle whatever you throw at them.

For maximum pizza production, consider the 93-inch Pizza Prep Table - it's like having a pizza-making command center. And don't miss our review of 3-Door Pizza Prep Fridges for serious storage solutions.

Best Prep Coolers for Delis, Cafes, and Salad Bars

Delis, cafes, and salad bars face a different challenge - variety. While a pizzeria might focus on perfecting one core product, these establishments need to juggle dozens of ingredients for sandwiches, wraps, salads, and prepared meals. Your prep cooler needs to be a master of organization.

Mega top tables shine in these environments. The expanded top rail accommodates more food pans or larger sizes, giving you the flexibility to offer an impressive array of meats, cheeses, vegetables, and dressings. This isn't just about storage - it's about creating a visual display that helps customers see their options and helps staff work efficiently.

The versatility of these units is remarkable. You can adjust the refrigerated section layout to accommodate different pan sizes, adapting as your menu changes with seasons or customer preferences. Whether you're crafting a complex custom sandwich or assembling a colorful salad, everything stays fresh and within easy reach.

Undercounter models deserve special mention for smaller spaces or specialized workstations. These units provide refrigerated storage directly beneath countertops, often with glass doors for easy visibility. They're perfect for grab-and-go items or as supplementary prep stations that keep specific ingredients exactly where you need them.

The real benefit for delis and cafes is handling high volumes of customized orders efficiently. When every order is different, having organized, accessible ingredients makes the difference between smooth service and chaos.

Check out an Undercounter Refrigerator with Glass Door for space-saving solutions. And for perfecting your ingredient display, our guide to The best topping stations for pros offers valuable insights for any foodservice operation.

Frequently Asked Questions about Prep Coolers

Running a commercial kitchen means dealing with lots of questions about your equipment. We've helped thousands of restaurant owners over the years, and these are the most common prep cooler questions we hear. Let's explore the answers that'll help you get the most out of your investment.

What is the ideal temperature for a prep cooler?

Getting the temperature right isn't just about keeping food cold – it's about keeping your customers safe and your business running smoothly. The sweet spot for prep coolers is 33°F to 41°F (0.5°C to 5°C). This range is what food safety experts call the "cold holding zone," and it's your best defense against harmful bacteria growth.

Here's why this range matters: Below 33°F, you risk freezing delicate ingredients like lettuce and tomatoes. Above 41°F, you're entering the danger zone where bacteria multiply rapidly. Most modern prep coolers come with digital controllers that make hitting this target easy. You can set it and forget it, though we always recommend checking temperatures regularly during busy shifts.

That frequent door opening during rush periods can cause temperature fluctuations. That's normal – just make sure your unit recovers quickly back to the safe zone. Your local health department might have specific requirements, so always check your local codes too.

How do I clean and maintain my prep cooler?

Think of maintenance like brushing your teeth – a little effort every day prevents big problems down the road. Your prep cooler needs the same kind of consistent care to keep running efficiently and safely.

Daily cleaning should become second nature. At closing time, remove all food pans, lids, and cutting boards. Wash and sanitize everything according to your standard procedures. Then grab a food-safe cleaner and wipe down all the stainless steel surfaces, paying extra attention to those ingredient wells where food bits love to hide.

Weekly deep cleaning is where you tackle the details. Check those door gaskets – they're like the weatherstripping on your car windows. Food particles and grime can build up there, causing air leaks that make your compressor work overtime. A quick scrub keeps everything sealed tight.

The monthly task that most people skip (but shouldn't) is cleaning the condenser coil. This is the part that actually removes heat from your unit. When it gets clogged with dust and grease, your prep cooler has to work much harder, using more energy and wearing out faster. A simple brush or vacuum cleaning takes just minutes but can add years to your equipment's life.

For the big stuff, consider professional servicing once or twice a year. It's like getting a tune-up for your car – an expert can spot potential problems before they become expensive repairs.

What is the warranty on a commercial prep cooler?

Warranty coverage is one of those things that seems boring until you need it. Most commercial prep coolers come with a standard warranty covering parts and labor for 1 to 3 years. This means if something breaks due to a manufacturing defect, you're covered for both the replacement part and the cost to install it.

The compressor usually gets special treatment with an extended warranty, often 2 to 4 years or longer. That makes sense since it's the most expensive and critical component of your refrigeration system.

But here's the catch – warranties have rules. They typically require proper use and maintenance, which means following the cleaning schedule we just talked about and using the equipment as intended. Most warranties won't cover damage from misuse, accidents, electrical problems, or acts of nature like floods or fires.

The best way to protect your warranty is simple: have your prep cooler installed by a qualified professional, train your staff properly, and keep up with regular maintenance. It's like insurance – you hope you never need it, but you'll be glad it's there if something goes wrong.

A good warranty is just one part of choosing the right equipment. Quality construction and reliable performance matter just as much for keeping your kitchen running smoothly day after day.

Upgrade Your Kitchen Workflow Today

Investing in a quality prep cooler is more than an equipment purchase; it's an upgrade to your entire kitchen operation. The benefits are clear: dramatic gains in efficiency, improved food quality from perfectly chilled ingredients, and higher customer satisfaction from faster, fresher orders.

At PizzaPrepTable.com, we understand that every kitchen has unique needs and budgets. That's why we offer a wide selection of top-tier prep coolers and related restaurant equipment, from compact units to massive mega-top models. We also provide flexible financing options to help you make this smart investment.

Our team offers expert advice custom to your specific needs, whether you're navigating a tight space, managing high volume, or working within a budget. We'll help you find the perfect balance of features and cost to transform your workflow.

Don't let inefficiency hold your business back. The right prep cooler can be the difference between struggling through service and sailing through it.

Ready to upgrade your kitchen? Explore our complete collection of Pizza Prep Tables and take the first step toward a smoother, more profitable operation.