Small Space, Big Taste: Countertop Pizza Prep Tables Reviewed

Share

The Ultimate Guide to Countertop Pizza Prep Stations

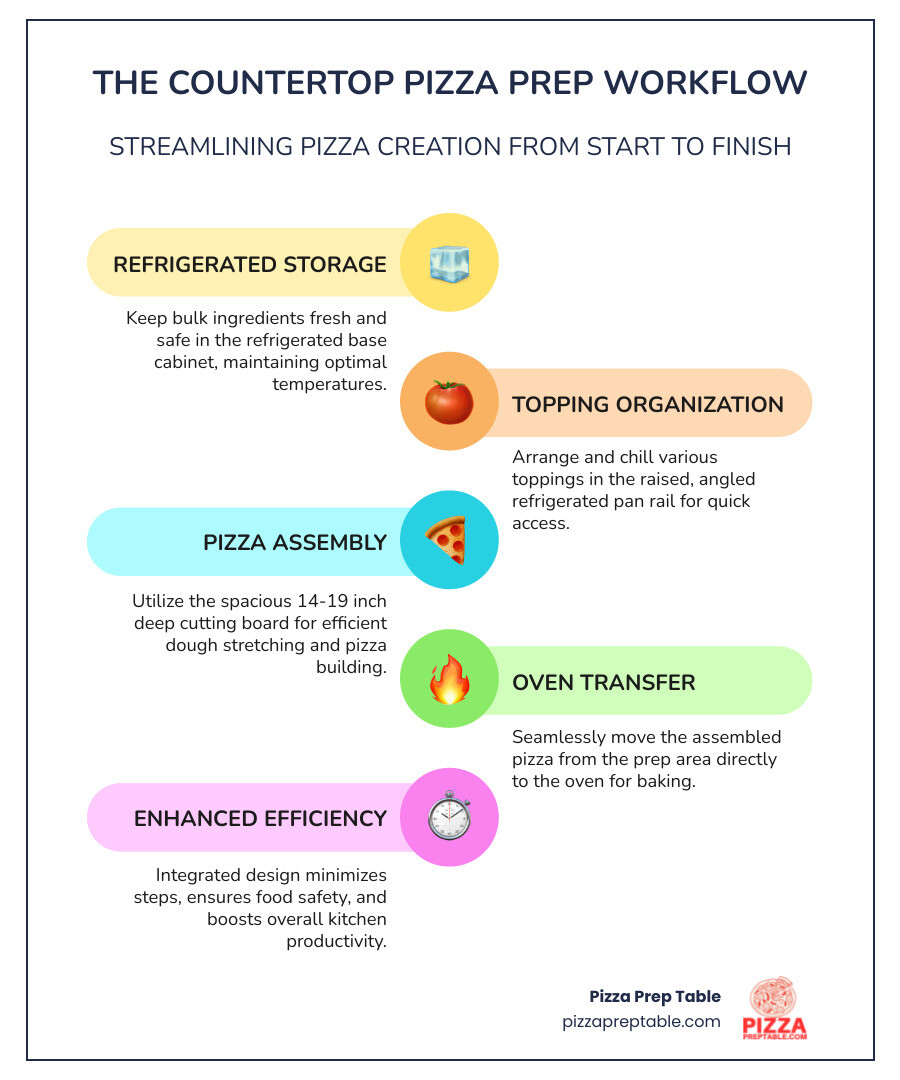

A countertop pizza prep table is essential equipment for any pizzeria or restaurant serving pizza. These compact refrigerated workstations combine ingredient storage, prep space, and cooling technology in one efficient unit.

Key Features of Countertop Pizza Prep Tables:

- Size Range: 44-60 inches wide to fit smaller kitchens

- Pan Capacity: 6-12 ingredient pans (1/3 or 1/6 size)

- Temperature Range: 33°F to 46°F for optimal food safety

- Cutting Board: 14-19 inch deep polyethylene or granite surface

- Storage: Refrigerated base with doors or drawers

- Construction: Stainless steel interior and exterior

These units are specifically designed with a raised, angled refrigerated rail that makes pizza assembly fast and efficient. Unlike sandwich prep tables with shallow 8-9 inch cutting boards, pizza prep tables feature deeper work surfaces to accommodate large pizza crusts.

The refrigerated pan rail keeps toppings at the perfect temperature while the spacious cutting board provides ample room for stretching dough and building pizzas. Most units maintain NSF-7 compliant temperatures and can keep ingredients fresh for hours, even with lids removed.

Modern countertop pizza prep tables use eco-friendly R290 refrigerant that can save up to 40% on energy costs compared to older systems. Leading brands are trusted by four of the top five pizza chains in the United States, proving their reliability in high-volume operations.

I'm Sean Kearney, and my experience in restaurant equipment sales has shown me how the right countertop pizza prep table can transform a small kitchen's efficiency and profitability. From helping small cafes to large restaurant chains, I've seen how these units maximize limited space while maintaining food quality.

At PizzaPrepTable.com, we understand the unique needs of commercial kitchens, especially when space is at a premium. Our mission is to supply top-tier commercial pizza prep tables, restaurant equipment, and kitchen appliances that boost efficiency and ensure quality. Whether you're a busy pizzeria in New York City or a cozy cafe in San Diego, we've got you covered. This guide will walk you through everything you need to know about selecting the perfect countertop pizza prep table to improve your culinary operations. It's the secret sauce behind efficient pizza prep stations.

Key Features to Look For in a Countertop Pizza Prep Table

Shopping for a countertop pizza prep table can feel overwhelming, but you don't need to be an engineer to pick the right one. You just need to know what matters for making great pizza efficiently.

Think of your prep table as your pizza operation's command center. Everything should be within arm's reach, chilled, and ready. The best units are intuitive, as if designed by someone who makes pizza for a living.

The refrigeration system is the heart of your prep table. Without reliable cooling, you risk health code violations. Your ingredients must stay between 33°F and 46°F consistently, even during your busiest rushes.

Pan capacity is key. A countertop pizza prep table is compact but can hold 6 to 12 pans in 1/3 or 1/6 sizes. The trick is matching capacity to your actual needs, not just wishful thinking.

For construction materials, there's no substitute for quality stainless steel. It looks professional, handles the daily abuse of a commercial kitchen, cleans easily, and won't harbor bacteria like cheaper materials.

Your cutting board deserves special attention. Look for a polyethylene surface at least 14 inches deep, though 19 inches is better for larger pies. Some premium models offer granite tops, which stay cooler and make dough handling easier.

Don't underestimate insulated lids. They work hard to maintain precise temperatures and keep ingredients from drying out. Good lids can make the difference between ingredients that last all day and those needing constant replacement. Check out our guide on stone cold deliciousness with granite and marble pizza prep tables for more on premium surfaces.

Essential Components and Materials

Let's review the components that make a great countertop pizza prep table. These features determine whether your prep table becomes your best friend or your biggest headache.

Stainless steel construction is the backbone of any serious prep table. Commercial-grade 304 stainless steel handles kitchen abuse, is antimicrobial, won't rust, and cleans up fast—which is critical during a dinner rush.

The polyethylene cutting board is your main workspace, so it must be good. These boards are typically removable for easy deep cleaning. The depth is critical; a few extra inches mean you can confidently stretch a large pizza without dough hanging over the edge.

Pan capacity directly impacts workflow efficiency. The refrigerated rail holds 1/3 and 1/6 size pans. The configuration should feel natural to your pizza-making process, so consider your most popular toppings and how you build pizzas when choosing a layout.

Digital temperature control removes the guesswork from food safety. These controllers provide precise readouts and often include automatic defrost cycles, so you'll always know the exact temperature inside your prep table.

Self-closing doors on the refrigerated base are a key detail for energy efficiency and food safety. When staff get busy and forget, these doors have your back. Many also feature a 90-degree stay-open function for easy loading before closing automatically.

Want to really step up your game? Learn how to prep like a pizza pro with these topping stations and make the most of every component.

Refrigeration Technology and Temperature Control

The cooling technology in your countertop pizza prep table works around the clock to keep your operation running smoothly. Understanding it helps you make better decisions and troubleshoot potential issues.

Forced-air cooling is the workhorse of most prep tables. A fan circulates cold air for even temperatures and quick recovery when lids are opened. It's reliable and effective, though aggressive airflow can sometimes dry out ingredients. The trade-off is excellent temperature consistency.

Cold-wall cooling is a more sophisticated approach. These systems create a "cold wall" above ingredient pans instead of just circulating air. This method keeps ingredients fresher and can allow you to shut down the rail at night for significant energy savings—up to 60%.

The shift to eco-friendly R290 refrigerant is a major development. This natural, non-toxic refrigerant can cut energy use by up to 40% compared to older systems. It's better for the environment and your bottom line—a true win-win.

Temperature range compliance is non-negotiable. Your prep table must meet the NSF-7 standard of keeping products at 41°F or below, even with lids open for four hours. The ideal range of 33°F to 46°F ensures safety while preserving ingredient quality.

Modern digital controls make monitoring temperatures effortless. You can see what's happening, adjust settings, and catch potential issues before they affect food quality. For more information about energy-efficient restaurant equipment, check out the resources at the SoCalGas Energy Resource Center.

Our Top Picks for the Best Countertop Pizza Prep Table

Finding the perfect countertop pizza prep table doesn't have to be a guessing game. After years of helping restaurants find their ideal equipment, I've narrowed down the field to three standout models that consistently deliver exceptional performance in compact kitchens.

These units prove that you don't need to sacrifice functionality for space. Each offers the essential features that make pizza prep efficient – from robust refrigeration systems to generous cutting boards – all while fitting comfortably in smaller kitchen layouts.

| Model | Dimensions (Approx. WxDxH) | Pan Capacity (1/3 size) | Cutting Board Material | Key Feature |

|---|---|---|---|---|

| Atosa MPF8201 (44-inch) | 44" x 31" x 40" | 6-8 | Polyethylene | Energy Star rated, Embraco compressor |

| True TPP-44 Compact | 44" x 32" x 41" | 6-8 | Polyethylene | Front-breathing, durable construction |

| Migali C-PP44 | 44" x 33" x 42" | 6-9 | Polyethylene (19.5" deep) | Deepest cutting board, forced air pan rail |

What makes these models special isn't just their compact size – it's how they maximize every inch of space while maintaining the reliability you'd expect from full-size units. These are among the best pizza tables for sale to slice your prep time, combining smart engineering with practical design.

Best Overall: Atosa MPF8201 44-Inch Prep Table

The Atosa MPF8201 represents everything I love about modern countertop pizza prep table design. At 44 inches wide, it strikes the perfect balance between functionality and footprint, making it ideal for kitchens where space is precious but performance can't be compromised.

What sets this unit apart is its Embraco compressor – a European-engineered powerhouse known for whisper-quiet operation and exceptional reliability. Paired with a Dixell digital controller, you get precise temperature management that keeps ingredients consistently between 33°F and 38°F. No more guessing games with analog dials.

The Energy Star rating isn't just good for the environment – it's great for your bottom line. Lower energy bills mean more money in your pocket, which is always welcome in the restaurant business. The stainless steel construction throughout ensures this investment will serve you well for years to come, even in the busiest kitchens.

You can learn more about Atosa pizza prep table options and why they're trusted by professionals worldwide.

Most Versatile: True TPP-44 Compact Prep Table

True Manufacturing has earned its reputation by building equipment that simply works, day after day, year after year. Their compact TPP-44 brings that legendary reliability to the countertop pizza prep table category with some clever design touches that make it incredibly versatile.

The front-breathing design is a game-changer for tight spaces. Unlike units that need clearance on the sides or back, this True model can sit flush against walls or other equipment without overheating. That flexibility alone can transform how you arrange your kitchen workflow.

Made in the USA construction means you're getting True's full attention to detail and quality control. The shallow depth doesn't compromise on pan capacity – True's engineers have mastered the art of maximizing interior space while minimizing the exterior footprint. The angled topping rail makes ingredient access effortless, even during your busiest rushes.

For more insights on selecting the right commercial pizza prep table for your operation, True consistently ranks among the top choices.

Best for High Volume: Migali C-PP44 Prep Table

When you need serious prep power in a compact package, the Migali C-PP44 delivers. This countertop pizza prep table is built for kitchens that don't have the luxury of space but can't afford to slow down during peak hours.

The standout feature here is the deep 19.5-inch cutting board – that's restaurant-grade prep space that gives you room to work with multiple pizzas or handle large dough balls without feeling cramped. The forced air pan rail ensures your toppings stay perfectly chilled even when you're moving fast and keeping lids open longer.

What really sets this unit apart for high-volume operations is its ability to accept 12" x 20" sheet pans in the refrigerated base. This means you can store more pizza dough balls in an organized way, reducing prep time and keeping your workflow smooth even during dinner rushes.

The digital controller gives you the precision control that busy kitchens demand, while Migali's reputation for durability means this investment will pay dividends for years to come. Check out more about prep tables for restaurant use and why Migali consistently ranks among the top performers.

Maximizing Food Safety and Freshness

When it comes to running a successful pizza operation, nothing matters more than keeping your customers safe and your ingredients at peak quality. Your countertop pizza prep table isn't just a convenient workspace – it's your first line of defense against foodborne illness and ingredient waste.

The magic happens in that critical temperature zone between 33°F and 41°F. This range isn't arbitrary – it's scientifically proven to slow bacterial growth to a crawl while keeping your toppings fresh and vibrant. When bacteria can't multiply, your customers stay healthy and your reputation stays intact.

This is where NSF certification becomes your best friend. When you see that NSF-7 stamp on a unit, you know it's been put through rigorous testing that would make a drill sergeant proud. These certified units must maintain proper temperatures even when staff forget to close lids or during those crazy dinner rushes when the prep table is constantly in use.

Insulated lids might look like simple covers, but they're actually sophisticated temperature guardians. Think of them as tiny blankets for your ingredients – they trap cold air and create a protective barrier against temperature swings. During slow periods or overnight, closing these lids can mean the difference between fresh-looking pepperoni and dried-out disappointment.

Smart operators know that proper temperature maintenance goes beyond just buying good equipment. Your digital temperature display is like a health monitor for your ingredients. Make it a habit to glance at those numbers throughout your shift. If something looks off, don't wait – address it immediately.

Cross-contamination prevention is where good design meets good habits. Your countertop pizza prep table naturally helps by keeping different ingredients in separate pans, but the real magic happens when your team uses dedicated utensils for each topping. That stainless steel surface and polyethylene cutting board aren't just easy to clean – they're designed to be sanitized quickly between tasks.

The beauty of modern prep tables is how they make food safety almost automatic. When you're slicing and dicing in style with your pizza prep chillers, you're not just creating delicious pizzas – you're building a foundation of trust with every customer who walks through your door.

Maintenance and Operational Best Practices

Let's be honest – nobody gets excited about cleaning equipment, but your countertop pizza prep table will reward you handsomely for a little TLC. Think of maintenance like seasoning a cast iron pan; the more love you give it, the better it performs.

The good news? Modern prep tables are designed with busy kitchens in mind. Those stainless steel surfaces aren't just for looks – they wipe down easily and resist stains. The polyethylene cutting board pops right out for washing, and most ingredient pans slide out without a fuss.

Daily cleaning should become second nature. A quick wipe-down of the exterior with mild detergent keeps fingerprints and splashes at bay. Remove that cutting board and give it a proper wash – it's your main workspace, after all. Don't forget the ingredient pans and their lids; they're in direct contact with your food. A gentle cleaning of the refrigerated pan rail ensures no stray cheese or sauce builds up over time.

Always glance at that digital temperature display. It should read between 33°F and 41°F consistently. If it doesn't, you'll want to investigate before your ingredients suffer.

Weekly maintenance is where you really protect your investment. The condenser coil is your unit's lungs – when it gets clogged with dust and grease, your compressor works overtime. Many newer models have removable filters that make this job surprisingly easy. Some premium units even feature self-cleaning condensers with rotating brushes, which is pretty neat technology.

Those door gaskets deserve attention too. They're the silent heroes keeping cold air where it belongs. Magnetic gaskets are fantastic because they pop off for cleaning without any tools. Check for tears or warping – a damaged gasket can cost you serious money in energy bills.

Ice buildup in unexpected places often signals defrost issues. Catching these early prevents bigger problems down the road. Your countertop pizza prep table should handle defrost cycles automatically, but it's worth keeping an eye on things.

Choosing the Right Countertop Pizza Prep Table for Your Layout

Here's where the rubber meets the road – or rather, where the prep table meets your kitchen floor. You can have the most feature-packed countertop pizza prep table in the world, but if it doesn't fit your space and workflow, it's just an expensive headache.

Measuring your space goes beyond just length and width. These units typically range from 44 to 60 inches wide, but depth matters too. That cutting board extends out from the unit – Migali's 19.5-inch deep board is generous for pizza making but needs room to breathe. You'll also need clearance for opening doors and accessing the back for cleaning.

Kitchen workflow is everything in a busy operation. Picture your pizza-making process: Where's your dough? Where's the oven? How far do your staff need to walk between stations? The goal is creating a smooth dance, not a chaotic scramble. Your prep table should feel like the natural center of this choreography.

Front-breathing designs are goldmines for tight spaces. Unlike units that need rear clearance for ventilation, these can sit flush against walls or other equipment. True Manufacturing is particularly known for this feature in their compact models.

Capacity planning involves more than counting ingredient pans. Consider your refrigerated base storage too. Do you need space for backup cheese bags, extra sauce containers, or sheet pans of dough balls? Some operations benefit from door configurations for bulk storage, while others prefer drawers for quick ingredient swaps during rush periods.

The compressor location might seem like a minor detail, but it affects placement options. Most units have right-side mounted compressors, but left-side options exist if your layout demands it. This small consideration can make the difference between a perfect fit and a frustrating compromise.

The best countertop pizza prep table is the one that makes your team's job easier, not harder. When equipment fits naturally into your workflow, everything runs smoother – from prep time to final product quality. It's all about finding that sweet spot where form meets function in your unique kitchen space.

Frequently Asked Questions about Pizza Prep Tables

After helping thousands of customers find their perfect countertop pizza prep table, I've noticed the same questions come up again and again. Let me share the answers to the most common ones – they might just solve a puzzle you didn't even know you had!

What is the difference between a pizza prep table and a sandwich prep table?

Here's where size really does matter! The main difference comes down to workspace and design. A countertop pizza prep table features a much deeper cutting board, typically ranging from 14 to 19 inches deep. Compare that to sandwich prep tables, which usually have a shallow 8 to 10-inch cutting board.

Why the difference? Try stretching a 16-inch pizza dough on an 8-inch surface – you'll quickly see the problem! Pizza prep tables also feature a raised, often angled refrigerated rail that makes it easy to grab toppings while you're working on those large pies. The angle puts everything at the perfect height and visibility.

Sandwich prep tables, on the other hand, have a flatter work surface since you're typically just assembling smaller items. It's like comparing a dining table to a coffee table – both serve their purpose, but you wouldn't want to eat Thanksgiving dinner on the coffee table!

How do I prevent ingredients in the rail from drying out?

This is probably the question that keeps pizza makers up at night! The secret weapon here is those high-quality, insulated lids. Think of them as little blankets for your ingredients – use them religiously, especially during slower periods and definitely overnight.

Your refrigeration system plays a huge role too. You want consistent, even cooling that maintains temperatures between 33°F and 41°F without being so aggressive that it creates a wind tunnel effect over your toppings. Nobody wants dried-out pepperoni that looks like little leather coins!

Some of the more advanced systems use cold-wall technology, which creates a gentle blanket of cold air over the pans. It's like having a protective shield that keeps everything fresh without the harsh air circulation that can dry things out.

Here's a pro tip from my years in the business: check your lids regularly for proper fit. Even small gaps can let cold air escape and warm air in, which leads to condensation and – you guessed it – dried-out ingredients.

What are the benefits of using an eco-friendly R290 refrigerant?

Now this is where we get into some exciting territory! R290 refrigerant is what I like to call the "triple win" solution – it's better for your wallet, better for the planet, and better for performance.

First, let's talk about your bottom line. Units using R290 can offer energy savings of up to 40% compared to older refrigerants like R134a. In a business where every penny counts, that's real money back in your pocket month after month.

From an environmental standpoint, R290 is a natural, non-toxic hydrocarbon refrigerant with an incredibly low Global Warming Potential (GWP). While older refrigerants can have GWPs in the thousands, R290 sits at just 3. It's like comparing a bicycle's environmental impact to a freight truck.

The performance benefits are impressive too. R290 systems often run more efficiently and quietly, which means less noise in your kitchen and more reliable temperature control for your ingredients. Plus, as environmental regulations continue to tighten, choosing R290 now means you're future-proofing your investment.

At PizzaPrepTable.com, we're proud to offer many models featuring this eco-friendly technology because we believe doing right by the environment and your business should go hand in hand.

Find the Perfect Prep Table for Your Pizzeria

After walking through all the features, comparisons, and maintenance tips, I hope you can see why the right countertop pizza prep table isn't just another piece of equipment – it's the foundation of an efficient pizza operation.

Think about it: when your ingredients stay perfectly chilled, your workspace is organized, and everything flows smoothly during the dinner rush, you're not just making better pizzas. You're creating a better experience for your team and your customers. That's what gets me excited about this business.

The efficiency boost alone can transform your kitchen. Instead of running back and forth to the walk-in cooler, everything you need is right at your fingertips. Your food quality improves because ingredients stay fresh longer in those perfectly controlled temperatures. And in today's competitive market, that space optimization can mean the difference between a cramped kitchen and one that actually works for you.

At PizzaPrepTable.com, we've seen how the right equipment changes everything. Whether you're running a cozy neighborhood spot in Portland or managing a busy location in Miami, we understand that every kitchen has unique needs. That's why we stock units for every situation – from compact 44-inch models perfect for tight spaces to larger units that can handle serious volume.

We also know that investing in quality equipment is a big decision. Nobody wants to stress about cash flow when they're trying to grow their business. That's exactly why we offer flexible financing options that work with your budget, not against it. You shouldn't have to choose between great equipment and keeping your doors open.

Ready to see what's possible? Explore our complete collection of commercial pizza prep tables and find how the right countertop pizza prep table can streamline your operation, boost your efficiency, and help you serve better pizza every single day.

Your perfect prep table is out there – let's find it together.