The Ultimate Pizza Topping Table Roundup

Share

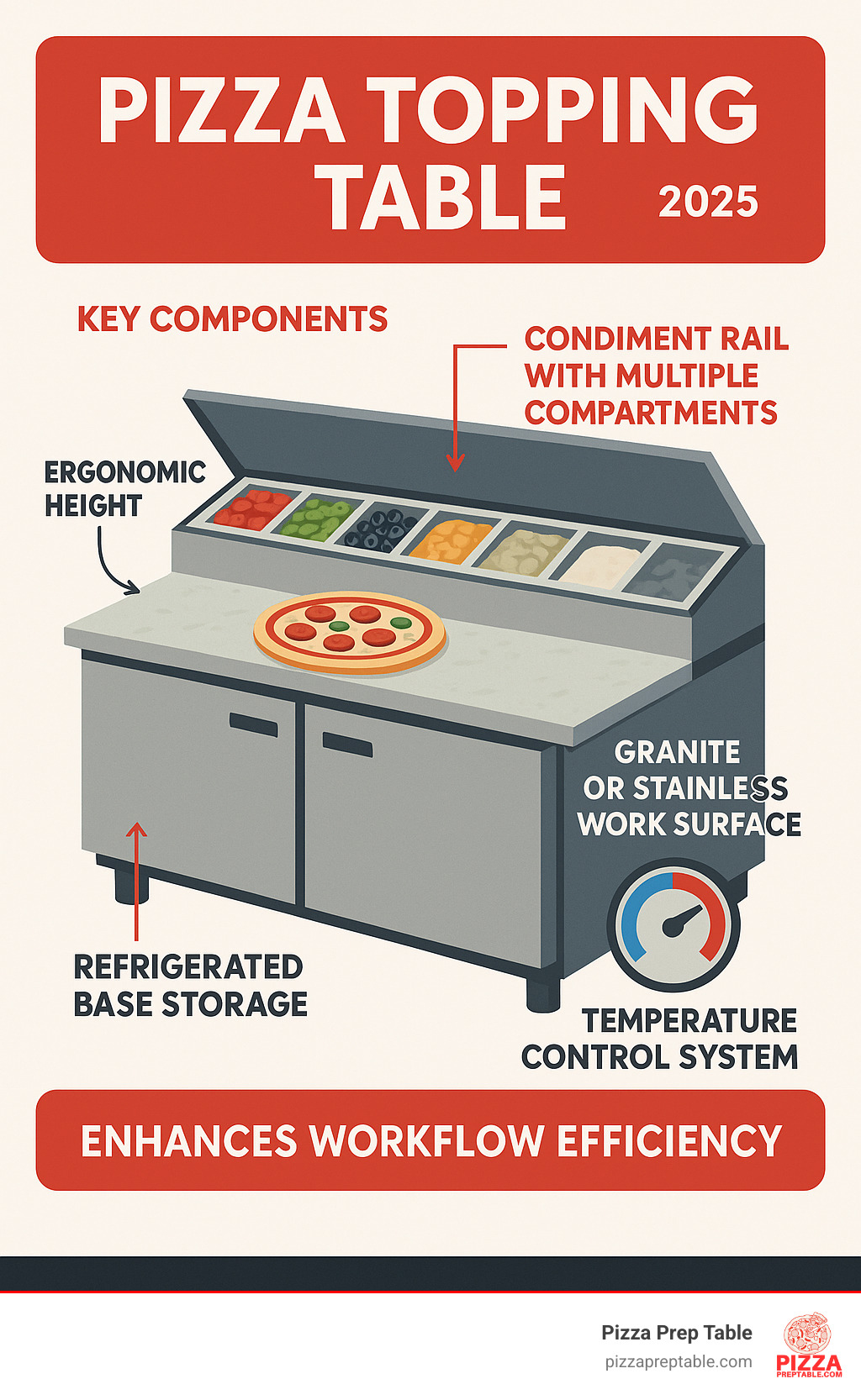

What is a Pizza Topping Table and Why Your Pizzeria Needs One

A pizza topping table is a specialized commercial refrigeration unit designed to keep pizza ingredients fresh and organized while providing a convenient work surface for assembling pizzas.

Key Features:

- Refrigerated compartments - Keep toppings at 33°F to 41°F for food safety

- Condiment rail - Up to 20 compartments for various toppings

- Work surface - Usually granite or stainless steel for easy prep

- Storage below - Doors or drawers for bulk ingredients

- Standard height - 32 to 36 inches for ergonomic use

Main Benefits:

- Streamlines pizza assembly workflow

- Maintains ingredient freshness and safety

- Reduces cross-contamination risks

- Saves valuable kitchen space

- Improves order consistency and speed

The primary function of these units is to keep your pizza toppings cold, organized, and within arm's reach while you work. This setup dramatically improves kitchen efficiency compared to running back and forth to walk-in coolers or separate prep areas. For pizzeria owners, the difference is night and day. Instead of juggling multiple storage locations, everything you need sits right in front of you, ensuring your ingredients remain fresh throughout busy dinner rushes.

I'm Sean Kearney, and my experience in restaurant equipment sales has shown me how the right pizza topping table can transform a struggling kitchen into an efficient operation. Proper equipment is a key driver of profitability and customer satisfaction.

Pizza topping table terms you need:

The Core Benefits for Your Business

Investing in a dedicated pizza topping table offers advantages that directly impact your bottom line and customer satisfaction.

- Streamlined Operations: In a busy pizzeria in a city like New York City or Chicago, every second counts. A well-designed pizza topping table puts all chilled toppings and bulk storage in one place. This cuts down on movement, speeds up assembly, and allows your team to prepare pizzas with rapid precision, creating a smoother, less chaotic work environment.

- Ingredient Organization: Pizza prep tables feature dedicated condiment rails, often with up to 20 compartments, for meticulous organization. Each ingredient has its spot, reducing errors, improving consistency, and allowing for easy visual inventory checks to manage stock and implement FIFO (First-In, First-Out) practices.

- Reduced Food Waste: By maintaining an optimal temperature between 33°F and 41°F (0.5°C to 5°C), these tables extend the shelf life of perishable ingredients. Preventing spoilage reduces food waste, which translates directly into cost savings for your business.

- Improved Hygiene: Constructed from easy-to-clean materials like stainless steel, pizza prep tables promote a more hygienic workspace. The ability to easily remove and clean cutting boards and food pans minimizes the risk of cross-contamination, ensuring your pizzas are prepared in a safe, sanitary environment.

- Consistent Pizza Quality: With ingredients kept at their ideal temperature and organized for easy access, your chefs can maintain uniform quality across every pie. Fresh, properly chilled ingredients not only taste better but also perform better during cooking, ensuring every pizza you serve in places like Philadelphia and San Diego lives up to your restaurant's high standards.

You can learn more about how these stations boost your operational flow by checking out The Secret Sauce Behind Efficient Pizza Prep Stations.

Our Top Pizza Prep Table Picks for 2025

Finding the perfect pizza topping table depends on your kitchen space, daily pizza volume, and budget. Today's market offers exceptional units to transform your kitchen's operation, whether you're in downtown Chicago or a neighborhood spot in Portland.

Commercial pizza prep tables range from compact 44-inch models to massive 119-inch workhorses. The main decisions involve choosing between door and drawer configurations and determining the amount of refrigerated storage you need.

Best for High-Volume Pizzerias: 3-Door Models

When your pizzeria is producing hundreds of pies, a 3-door pizza topping table is your kitchen's MVP. These units typically span 91 to 94 inches, providing significant space for pizza assembly.

The primary benefit is large capacity storage. Three refrigerated compartments below the work surface let you store large quantities of cheese, sauce, and toppings without constant restocking. This extra capacity is crucial during busy rushes.

What truly sets 3-door models apart is their support for multiple workstations. Two or three pizza makers can work side-by-side, accessing the same condiment rail. This setup dramatically increases your high output potential without creating kitchen chaos. These units are built for demanding conditions, maintaining perfect temperatures at high speed. For pizzerias maximizing efficiency, check out our guide to 3-Door Pizza Prep Fridges That'll Make You Say Cheese. The 93-Inch Pizza Prep Table is a popular choice for high-volume operations.

Best for Compact Kitchens: 2-Door Models

For kitchens with limited square footage, 2-door models offer a perfect solution without sacrificing quality. These space-saving designs typically range from 44 to 72 inches wide, fitting comfortably into tighter layouts while packing impressive functionality.

Their versatile configurations are a key feature. Many have adjustable shelving, drawer combinations, or hybrid door-drawer setups to maximize storage for dough, cheese, and other ingredients.

For small to medium businesses, these tables provide dedicated prep space and proper refrigeration without overwhelming your kitchen or budget. They are particularly appealing to food trucks, casual dining spots, and neighborhood pizzerias.

Explore our Slice and Dice with Ease: 2-Door Pizza Prep Fridges Reviewed to find your match. The 67-Inch Pizza Prep Table is a customer favorite for its balanced size and performance.

Top Brands to Consider

Choosing the right brand for your pizza topping table is crucial for long-term success. Here are some manufacturers that consistently deliver reliability, performance, and value:

- Atosa: Known for robust stainless steel construction and dependable refrigeration systems that maintain proper temperatures during heavy use. Learn more about why pizzerias choose Atosa Pizza Prep Table units.

- True Manufacturing: A premium brand offering exceptional build quality, innovative features, advanced temperature control, and energy-efficient designs that save money over time.

- Dukers: Provides excellent value without compromising on essential features. Their tables offer reliable performance at competitive prices, making them popular among independent pizzeria owners. See why in our guide to Top Dukers Pizza Prep Tables to Keep Your Dough Cool and Your Customers Happy.

Each brand offers unique strengths, but all are committed to helping your pizzeria succeed. The key is matching their products with your specific operational needs and budget.

Key Features of the Best Pizza Topping Table

A high-quality pizza topping table is the heart of your pizza-making station. The best models combine key features that ensure efficiency, food safety, and durability. This includes strong refrigeration, a top-notch work surface, smart storage, and a handy condiment rail.

Work Surface Materials: Granite vs. Stainless Steel

The work surface is where you stretch dough and assemble pizzas, so the material choice affects workflow, cleanliness, and even pizza quality. The most common choices are granite and stainless steel.

| Feature | Granite Work Surface | Stainless Steel Work Surface |

|---|---|---|

| Material | Solid natural stone (often 30-inch deep) | Food-grade stainless steel |

| Durability | Extremely durable, scratch, and heat resistant | Highly durable, corrosion-resistant |

| Temperature | Stays naturally cooler, ideal for dough and ingredients | Conducts temperature, can warm up faster |

| Cleaning | Smooth, non-porous, easy to wipe clean | Smooth, non-porous, easy to wipe clean |

| Aesthetics | Premium look, often preferred by artisanal pizzerias | Professional, industrial look, common in commercial kitchens |

| Ergonomics | Provides a solid, stable surface for kneading and stretching | Solid surface for prep |

A pizza topping table with a granite work surface is a great choice for dough work. Granite stays naturally cool, which prevents dough from sticking or rising too quickly in a warm kitchen. This helps maintain perfect dough consistency. Granite is also extremely durable, scratch-resistant, and easy to clean. For a premium look and feel, explore these options at Stone Cold Deliciousness: Granite and Marble Pizza Prep Tables Reviewed.

Stainless steel work surfaces are the workhorse of commercial kitchens. This material is incredibly durable, corrosion-resistant, and easy to sanitize, as its non-porous surface doesn't harbor bacteria. While it doesn't stay cool like granite, it's an excellent, practical choice for busy establishments that need robust, long-lasting equipment.

Understanding Refrigeration and Temperature Control

The refrigeration system is the engine of any pizza topping table. Proper temperature control is essential for both food safety and ingredient quality.

The ideal temperature range is between 33°F and 41°F (0.5°C to 5°C). This narrow window is vital for keeping perishable ingredients out of the temperature "danger zone," where harmful bacteria can grow rapidly. Adhering to this range is a requirement for passing health inspections in cities like Phoenix or San Antonio.

Beyond safety, proper refrigeration preserves the quality of your ingredients. It keeps vegetables crisp, cheeses firm, and meats fresh, contributing to a superior and consistent final product. Many modern pizza topping table units use energy-efficient, eco-friendly refrigerants like R290 hydrocarbon, which are designed for performance while meeting environmental regulations. For more energy-saving ideas, see these Energy efficiency tips from SoCalGas.

Choosing the Right Size for Your Pizza Topping Table

Picking the right size pizza topping table depends on your kitchen layout, daily pizza volume, and topping variety.

Units come in many sizes, from compact 44-inch models to expansive 119-inch units. Most tables are 32 to 36 inches (81 to 91 cm) tall, an ergonomic height designed to reduce strain on chefs during long shifts.

These tables are designed to hold standard food pans, often up to 6 inches deep. The condiment rail can hold up to 20 pans on some models, while the refrigerated base offers ample bulk storage for full-size sheet pans or dough trays. Choosing the right size ensures your pizza topping table fits your workflow, whether you're in Seattle or Charlotte. For a general overview, visit Prep Tables for Restaurant.

Pizza Prep Tables vs. Sandwich Prep Tables: What's the Difference?

When shopping for equipment, you might wonder if a pizza topping table is different from a sandwich prep table. While both keep ingredients cold, they are designed for different tasks, and choosing the wrong one can impact your kitchen's efficiency.

The main difference is size and scale. Pizza making requires more space than sandwich assembly, from stretching large doughs to adding generous amounts of toppings.

Design Differences Explained

The most obvious difference is the deeper cutting board on a pizza prep table. While sandwich tables may have a 10- or 12-inch deep surface, pizza prep tables feature cutting boards that are 18 to 30 inches deep. This extra space is essential for working with large pizza crusts, like 18" x 26" sheet pan pizzas, without ingredients falling off the sides.

Accommodating large pizza crusts requires a generous work surface that allows your team to move freely. Trying to use a smaller sandwich table can lead to a cramped, inefficient workflow.

The deeper food pans in pizza prep tables are another key distinction. These units can hold pans up to 6 inches deep, which is crucial for the high volume of toppings a busy pizzeria uses. A single rush might require pounds of mozzarella and heaps of vegetables. Sandwich tables use shallower pans, as their ingredients don't require the same bulk storage.

Pizza topping volume is a major consideration. A successful pizzeria needs to keep large quantities of various toppings chilled and within easy reach. The condiment rails on pizza prep tables are designed for this, often featuring up to 20 compartments to handle the variety and volume that pizza service demands.

If you're still curious, you can compare them to a Sandwich Prep Table Refrigerator, but for pizza making, there's no substitute for purpose-built equipment.

Best Practices for Cleaning and Maintenance

A well-maintained pizza topping table is essential for a smooth-running kitchen, fresh ingredients, and safe, delicious pizza. This isn't just about passing health inspections in cities like Columbus or Denver; it's about protecting your reputation and bottom line.

A consistent cleaning schedule with daily and weekly tasks is the best approach. This proactive method prevents issues and extends your equipment's lifespan.

Daily Tasks:

- Wipe all surfaces: Use a mild detergent solution to wipe down all interior and exterior surfaces, removing food particles and preventing buildup.

- Wash and sanitize food pans: Remove all food pans, wash them with hot, soapy water, and sanitize them according to local health guidelines before refilling.

- Clean the cutting board: Remove, wash, and sanitize the cutting board daily. Ensure it's completely dry before returning it.

Weekly Checks:

- Clean the condenser coil: Dust and grease can build up on the condenser coil, forcing the unit to work harder and use more energy. Use a brush or vacuum to clean the coils weekly or bi-weekly.

- Inspect door gaskets: Check the rubber door seals for any tears or wear. A damaged gasket leaks cold air, reducing efficiency and compromising food safety. Replace worn gaskets immediately.

- Check drain lines: Ensure drain lines are clear to prevent water from building up inside the unit.

By following these best practices, your pizza topping table will run efficiently and safely for years. For help or parts, you don't have to lose your cool: Don't Lose Your Cool: Where to Find Pizza Prep Table Parts.

A Step-by-Step Guide to Cleaning Your Pizza Topping Table

Here’s a simple guide to keep your pizza topping table sparkling and efficient:

- Empty and Power Down: Remove all food and pans. For safety, unplug the unit or switch off its power at the circuit breaker.

- Initial Wipe-Down: Use a soft cloth dampened with a mild, food-safe detergent to wipe all interior and exterior surfaces, focusing on spills or sticky spots.

- Clean Pans and Cutting Board: Wash, rinse, and sanitize all food pans and the cutting board. Let them air dry completely.

- Detail the Condiment Rail: Use a small brush or cloth to clean any crevices within the condiment rail.

- Condenser Coil Care (Weekly/Bi-weekly): Locate the condenser coils (usually at the back or bottom) and gently remove any built-up dust or grease with a stiff brush or vacuum attachment.

- Check Gaskets: Inspect the door gaskets for damage. Clean them with warm, soapy water. If they are torn or brittle, they should be replaced.

- Final Wipe-Down: Give the entire unit a final wipe with a clean, damp cloth to remove any detergent residue, then dry it with a clean towel.

- Power Up and Restock: Plug the unit back in, allow it to reach its set temperature, and then restock it with fresh ingredients.

Frequently Asked Questions about Pizza Topping Tables

We get a lot of questions about pizza topping tables from customers in cities from San Diego to Phoenix. Here are the answers to the most common inquiries we receive at PizzaPrepTable.com.

What is the ideal temperature for a pizza prep table?

The ideal temperature for a pizza topping table is between 33°F and 41°F (0.5°C to 5°C). This range is critical for food safety, as it keeps perishable ingredients like cheese, meat, and vegetables out of the temperature "danger zone" where bacteria multiply rapidly. Proper temperature also preserves the quality, texture, and taste of your toppings, ensuring a better final product.

How tall are pizza prep tables?

Most commercial pizza topping tables have a working height between 32 and 36 inches (81 to 91 cm). This specific height range is designed for ergonomic comfort, allowing chefs to work efficiently for long shifts without straining or bending over. This design helps reduce fatigue and improve productivity in busy kitchens in places like San Antonio or Austin.

What are the common voltage requirements?

The vast majority of pizza topping tables in the US operate on a standard 115V or 120V electrical connection. This means they can be plugged into a regular commercial outlet without needing special or expensive wiring, which simplifies installation and keeps setup costs down. However, it's always a good practice to double-check the electrical specifications for your specific model before purchase.

Conclusion: Find the Perfect Pizza Topping Table for Your Kitchen

When a pizzeria installs the right pizza topping table, the entire workflow can transform from chaotic to efficient. This single piece of equipment is the foundation that boosts efficiency, ensures food safety, and improves product quality.

Your pizza topping table keeps ingredients fresh, organized, and within arm's reach. By maintaining the crucial 33°F to 41°F temperature range, it keeps toppings perfectly chilled and ready for service. This investment pays for itself through faster service, reduced food waste, and the consistency that builds customer loyalty.

At PizzaPrepTable.com, we've seen how the right equipment transforms businesses. We understand that every kitchen has unique needs, which is why we offer a wide selection of commercial pizza prep tables. We also provide financing options to make this crucial investment accessible to both small independent shops and larger establishments.

Whether you need a compact 2-door model or a massive 3-door workhorse, we have a solution that fits your workflow, space, and budget.

Ready to take your pizza game to the next level? Explore our complete collection of Pizza Prep Tables and find how the right equipment can make your kitchen extraordinary.