Walk-In Wonders: Why Your Restaurant Needs a Commercial Refrigerator

Share

Why Every Commercial Kitchen Needs a Walk-In Refrigerator

A walk in refrigerator is a room-sized cooling unit that maintains temperatures between 0°C and 13°C (32°F to 55°F) for storing perishable foods. These units offer far more storage than standard reach-in refrigerators, making them essential for restaurants, pizzerias, and any foodservice operation storing ingredients in bulk.

Key benefits of walk-in refrigerators:

- Massive storage capacity - Store whole cases of ingredients, large produce deliveries, and bulk items.

- Food safety compliance - Maintain consistent temperatures to prevent spoilage and meet health regulations.

- Cost efficiency - More economical than multiple smaller units for high-volume operations.

- Easy organization - Walk-in access allows for better inventory management and FIFO rotation.

- Space optimization - Outdoor models free up valuable indoor kitchen space.

Most restaurants find walk-in coolers essential for daily service. Whether you're opening a new pizzeria or upgrading your kitchen, understanding this equipment is key to making a smart investment. With prices ranging from £5,000-£20,000 plus installation, choosing the right unit from the start is crucial, especially for owners with tight budgets.

My name is Sean Kearney, and with years of experience in foodservice operations, I've helped countless owners select the perfect walk in refrigerator. In this guide, I'll walk you through everything you need to know to make the best choice for your business.

The Anatomy of a Walk-In Cooler: Key Components and How They Work

While a walk in refrigerator may look like a simple metal box, it's a sophisticated piece of engineering. Understanding how it works helps you spot problems early, make smart maintenance decisions, and protect your inventory. This knowledge is invaluable when discussing issues with a technician and can save you money and stress.

Core Components You Need to Know

- Insulation Panels: These panels are your first line of defense against heat. They consist of high-density polyurethane foam between durable metal sheets. Look for a high R-value, which indicates better heat resistance, leading to lower energy bills and more stable temperatures.

- Doors: A walk-in door is a system with self-closing hinges and heavy-duty gaskets that create an airtight seal. The gasket is critical for preventing cold air from escaping and keeping energy costs down.

- Flooring: While some units can be installed on existing concrete, many include insulated floors for extra thermal protection. Slip-resistant floors are a key safety feature in a potentially wet environment.

- Lighting: Modern LED lighting improves visibility and reduces energy use. Many units also feature occupancy sensors that automatically turn lights on and off, offering significant long-term savings.

The Refrigeration Cycle Explained

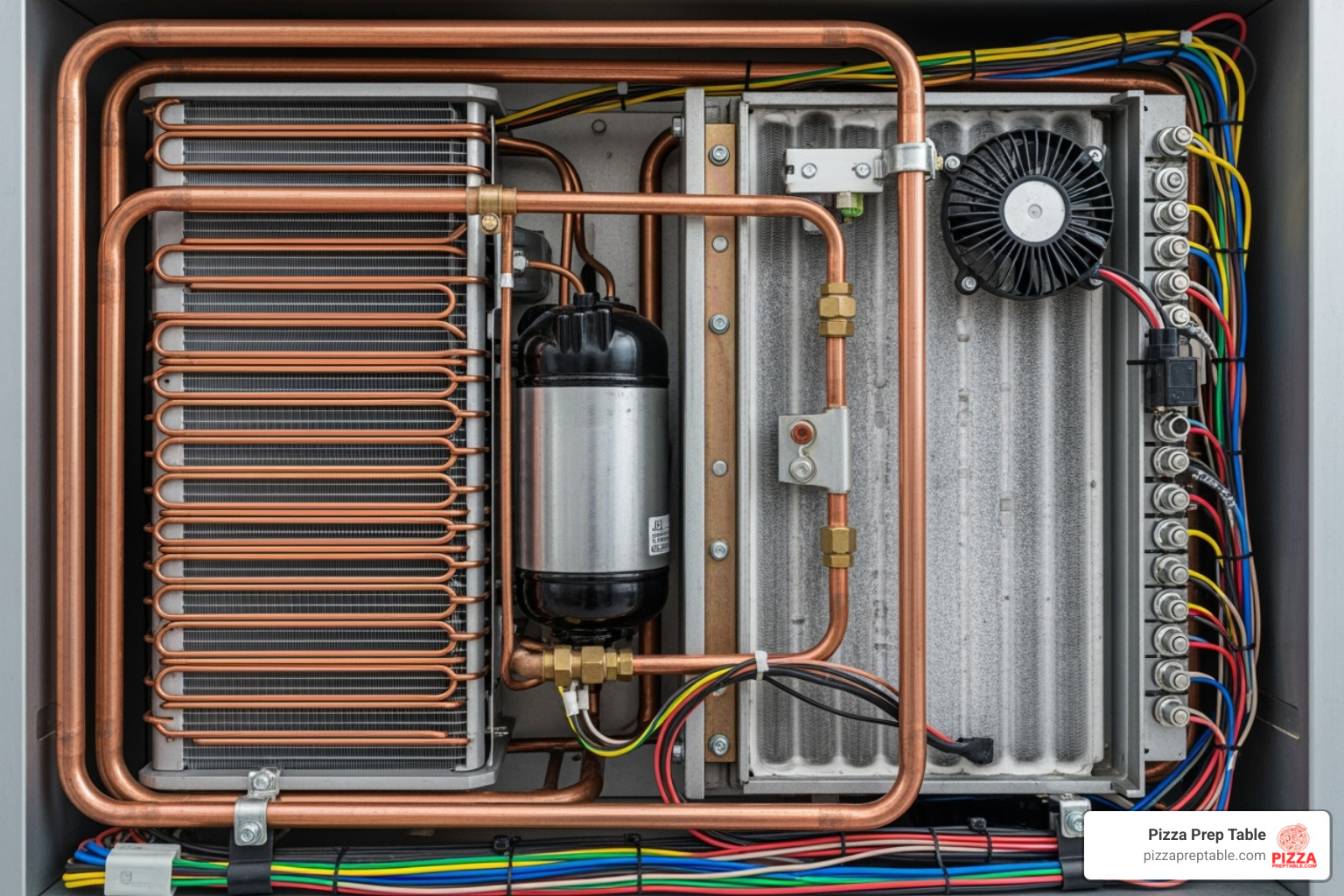

A walk in refrigerator doesn't create cold; it removes heat. The system moves heat from inside the cooler to the outside through a continuous cycle.

- The compressor, the heart of the system, pumps refrigerant through a loop.

- Inside the walk-in, the refrigerant passes through evaporator coils, absorbing heat from the air and turning from a liquid to a gas. This heat exchange process cools the interior.

- The heated gas is pumped to the condenser (usually outside the cooler), where it releases the heat and turns back into a liquid.

- A thermostat control regulates this cycle to maintain the set temperature.

This sequence is the vapor-compression refrigeration cycle.

The defrost cycle is an important function that prevents ice buildup on the evaporator coils by periodically warming them, ensuring the unit runs efficiently.

Essential Safety and Security Features

Safety is non-negotiable for large refrigerated spaces. Every walk in refrigerator must have an interior safety release handle, a code-required feature that allows anyone inside to open the door.

Lockable doors are essential for protecting your inventory and controlling access after hours. Temperature alarms provide an early warning if temperatures move outside the safe range, helping prevent spoilage. Advanced monitoring systems can even send alerts to your phone, offering peace of mind. These features are vital for maintaining Food Safety Guidelines for Restaurants and ensuring smooth operations.

Choosing the Perfect Walk-In Refrigerator for Your Business

Selecting the right walk in refrigerator is critical. The wrong choice can lead to cramped storage or excessive energy bills. Before buying, consider your weekly food volume, what ingredients you need to store, and where the unit will be placed. Answering these questions will guide you to the ideal solution for your business.

Sizing and Placement: Finding the right walk in refrigerator

Location is a key decision with two main options:

- Indoor units are placed directly in your kitchen, offering convenient access for staff. They can be configured in L-shapes or other custom forms to fit awkward spaces. However, they consume valuable kitchen real estate, which can be a major drawback in smaller venues.

- Outdoor units are weatherproof and sit outside your building, freeing up significant indoor space for prep areas or other equipment. This can lead to substantial savings on construction or renovation costs. Modern weatherproofing ensures these units can withstand harsh conditions. This approach helps optimize your Commercial Kitchen Layout Design.

When calculating the required footprint, always account for door swing and maintenance access.

Types of Refrigeration Systems

- Self-contained systems are all-in-one units, usually mounted on top of the walk-in. They are simpler and cheaper to install but release heat into your kitchen, potentially increasing air conditioning costs.

- Remote systems place the noisy, heat-producing compressor and condenser outside or in a separate room. This keeps the kitchen cooler and quieter and often improves energy efficiency.

- Split systems are similar to remote systems and are a popular choice for larger units where reducing kitchen heat and noise is a priority.

These systems can be top-mount, wall-mount, or side-mount, describing where the equipment is located on the walk-in box.

Walk-In Cooler vs. Walk-In Freezer

Temperature is the defining difference. Walk-in coolers operate between 0°C and 13°C (32°F to 55°F), ideal for fresh produce and dairy. Most are kept around 4°C (40°F) for food safety.

Walk-in freezers run at or below 0°C (32°F), typically around -18°C (0°F), for long-term storage of frozen goods. Combo units, which feature both a cooler and freezer section in one structure, are a space-efficient option. Our Keep Cool and Carry On: The Ultimate Commercial Fridge-Freezer Combo Guide explores these versatile units.

Custom vs. Standard Models

- Quick-ship models are standard-sized units (e.g., 6x8x8H) that are affordable and readily available, perfect for straightforward needs.

- Custom-designed units are engineered for unique spaces. Reputable manufacturers can create L-shapes, angled walls, or even specialized beer caves to fit your exact requirements. The custom route costs more and takes longer but is often the best solution for maximizing workflow in non-standard layouts. Many manufacturers offer both custom and quick-ship options.

The Financial Breakdown: Costs, Efficiency, and ROI

A walk in refrigerator is a major investment, but it's one that pays dividends in operational efficiency and profitability. A quality unit can last 15+ years, and when you factor in the food waste it prevents, the long-term value becomes clear. For help with upfront costs, consider exploring Restaurant Equipment Financing for Startups.

Understanding the Cost of a Walk-In Refrigerator

Expect to invest £5,000 to £20,000 for the unit, plus around £500 for installation. This wide range is influenced by several key factors:

- Size: This is the biggest cost driver. A larger unit requires more materials, insulation, and refrigeration power.

- Brand and Quality: Reputable manufacturers like Norbec, Arctic Industries, and others may cost more upfront but offer superior reliability, warranties, and parts availability, saving you money on future repairs.

- Custom Features: Custom shapes, specialized doors, or advanced monitoring systems increase the price but can be worth it for improved workflow and space maximization.

- Refrigeration System: Remote or split systems have higher initial costs but can offer long-term savings through better energy efficiency.

- Flooring and Materials: Insulated flooring and premium materials like stainless steel increase the upfront cost but deliver better performance and longevity.

For a complete picture of budgeting, see our Restaurant Startup Costs Breakdown.

Maximizing Energy Efficiency and Meeting Regulations

Since your walk in refrigerator runs 24/7, energy efficiency directly impacts your bottom line. The Department of Energy (DOE) and Environmental Protection Agency (EPA) set standards that push manufacturers to build more efficient units. Choosing a unit that meets or exceeds current and upcoming regulations (like those effective January 1, 2025) will lower your utility bills.

Key features for energy savings include:

- High R-value insulation: Quality polyurethane insulation (R-32 or higher) acts as an efficient thermal barrier, reducing the workload on your refrigeration system.

- LED lighting with occupancy sensors: This combination can cut lighting energy consumption by up to 80%.

- Strip curtains: Installing these plastic strips inside the door is a low-cost way to create a thermal barrier and reduce cold air loss by 30% or more.

- Efficient components: Look for high-efficiency compressors and ECM fan motors that use less energy to maintain temperature.

- Smart controls: These can automatically adjust fan speeds or refrigeration cycles to optimize energy use.

Investing in an energy-efficient unit lowers operating costs and supports your efforts in Reducing Food Waste in Restaurants by ensuring optimal storage conditions.

Installation, Maintenance, and Organization

Proper installation and ongoing maintenance are crucial for protecting your walk in refrigerator investment and ensuring its longevity. Smart organization will further improve its efficiency and support smooth kitchen operations.

Best Practices for Installation

Professional installation is essential for performance and safety. This is not a DIY project. Key considerations include:

- Site Preparation: The installation area must be perfectly level to ensure doors seal correctly and to prevent stress on the unit's frame. Outdoor sites require proper drainage.

- Electrical Requirements: Walk-in systems need dedicated circuits installed by a licensed electrician to meet safety codes.

- Ventilation: Self-contained indoor units generate significant heat and require adequate airflow to operate efficiently. Additional ventilation may be necessary.

Due to the weight and complexity of refrigeration systems, professional installers with the right equipment and expertise are necessary to handle the job safely.

Essential Maintenance for Longevity

A well-maintained walk in refrigerator can last 15+ years. Regular maintenance improves energy efficiency, ensures food safety, and prevents costly breakdowns.

- Monthly Deep Cleaning: Empty the unit completely and clean all surfaces with food-safe cleaners to prevent odors and bacteria.

- Check Door Seals: Regularly inspect rubber gaskets for cracks or warping. A damaged seal forces the compressor to work harder, increasing energy costs. Replace them immediately.

- Clean Condenser Coils: These coils collect dust and grease, which reduces efficiency. Clean them monthly in busy kitchens or quarterly otherwise.

- Monitor Temperature: Use reliable thermometers to log temperatures. Fluctuations can signal a developing problem.

- Schedule Professional Servicing: Have a qualified technician perform an annual or semi-annual check-up to inspect refrigerant levels, electrical connections, and other components.

Organizing Your Walk-In and Top Brands

An organized walk in refrigerator saves time and reduces food waste. Use heavy-duty, adjustable wire shelving to promote air circulation. Always follow the FIFO (First-In, First-Out) system by clearly labeling all items with received and expiration dates. For more ideas, see our guide on Maximize Your Mobile Kitchen: Essential Food Truck Shelving Strategies.

When choosing a unit, several manufacturers have earned trust through consistent performance. Norbec is known for custom solutions and innovative features. Arctic Industries has over 40 years of experience with both custom and quick-ship models. Other reliable brands include Amerikooler, Nor-Lake, and Kolpak, all of whom offer a range of solutions that meet modern efficiency standards and serve businesses nationwide.

Frequently Asked Questions about Walk-In Refrigerators

We hear a lot of questions about walk-in refrigerators, and for good reason—they're a significant investment and a critical part of any foodservice operation. Let's tackle some of the most common ones.

What is the ideal temperature for a commercial walk-in cooler?

For optimal food safety and freshness, the ideal temperature for a commercial walk in refrigerator should be at or below 4°C (40°F). Many operations aim for a steady 35-38°F (1.7-3.3°C). The research confirms that walk-in refrigerators operate above 0°C and at or below 13°C. This range helps inhibit bacterial growth and keeps your perishable ingredients in prime condition. However, always remember to check product-specific temperature recommendations, as some items might require slightly different storage conditions.

How long does a walk-in refrigerator typically last?

With proper installation and diligent maintenance, a high-quality walk in refrigerator can last a surprisingly long time. Our specialists estimate that you should expect your refrigerator to last around 15 years. However, with excellent maintenance and decent care, they can last well beyond that, sometimes 20 years or more! Factors affecting longevity include:

- Build Quality: Units from reputable manufacturers with robust construction and good insulation tend to last longer.

- Maintenance: Regular cleaning of coils, checking door seals, and professional servicing are crucial. Neglecting these can significantly shorten lifespan.

- Usage: Units in high-volume, constantly busy kitchens might experience more wear and tear than those in less demanding environments.

- Installation Quality: A poor installation can lead to premature issues and reduce the unit's lifespan.

Can a walk-in cooler be installed outside?

Yes, absolutely! The short answer is yes. Many commercial kitchens, especially in space-constrained urban areas like New York City or Chicago, opt for outdoor walk in refrigerator installations to free up valuable interior kitchen space. The seamless construction of a walk-in freezer (and many coolers) allows the unit to be set outside without the use of a roof cap or any other type of expensive protection.

Outdoor units are specifically designed to be weatherproof, so you won’t have to worry about the elements or leakage. They require little to no assembly in terms of external protection. This flexibility makes them an excellent solution for maximizing storage without compromising your kitchen layout. Just ensure a proper, level foundation and easy access for deliveries and staff.

Conclusion

Choosing the right walk in refrigerator is a foundational decision for your restaurant. It's an investment in your food storage system, ingredient quality, and food safety compliance. A well-chosen unit provides massive storage, ensures regulatory compliance, and saves money through energy efficiency.

The key takeaways are to carefully consider size and placement, prioritize energy efficiency to lower your operating costs, and commit to proper maintenance to ensure your unit lasts for 15+ years. From storing cases of mozzarella to organizing daily prep, your walk in refrigerator is the cornerstone of a successful commercial kitchen.

At PizzaPrepTable.com, we understand that the right refrigeration is as crucial as the perfect pizza prep table. We've helped countless restaurant owners make these important decisions, and we're here to help you too.

Ready to build your dream kitchen? Explore our full range of commercial kitchen equipment and let's get your operation running smoothly.