Pizza Prep Counters That Slice Through the Competition

Share

Why Pizza Prep Counters Are Essential for Modern Pizzerias

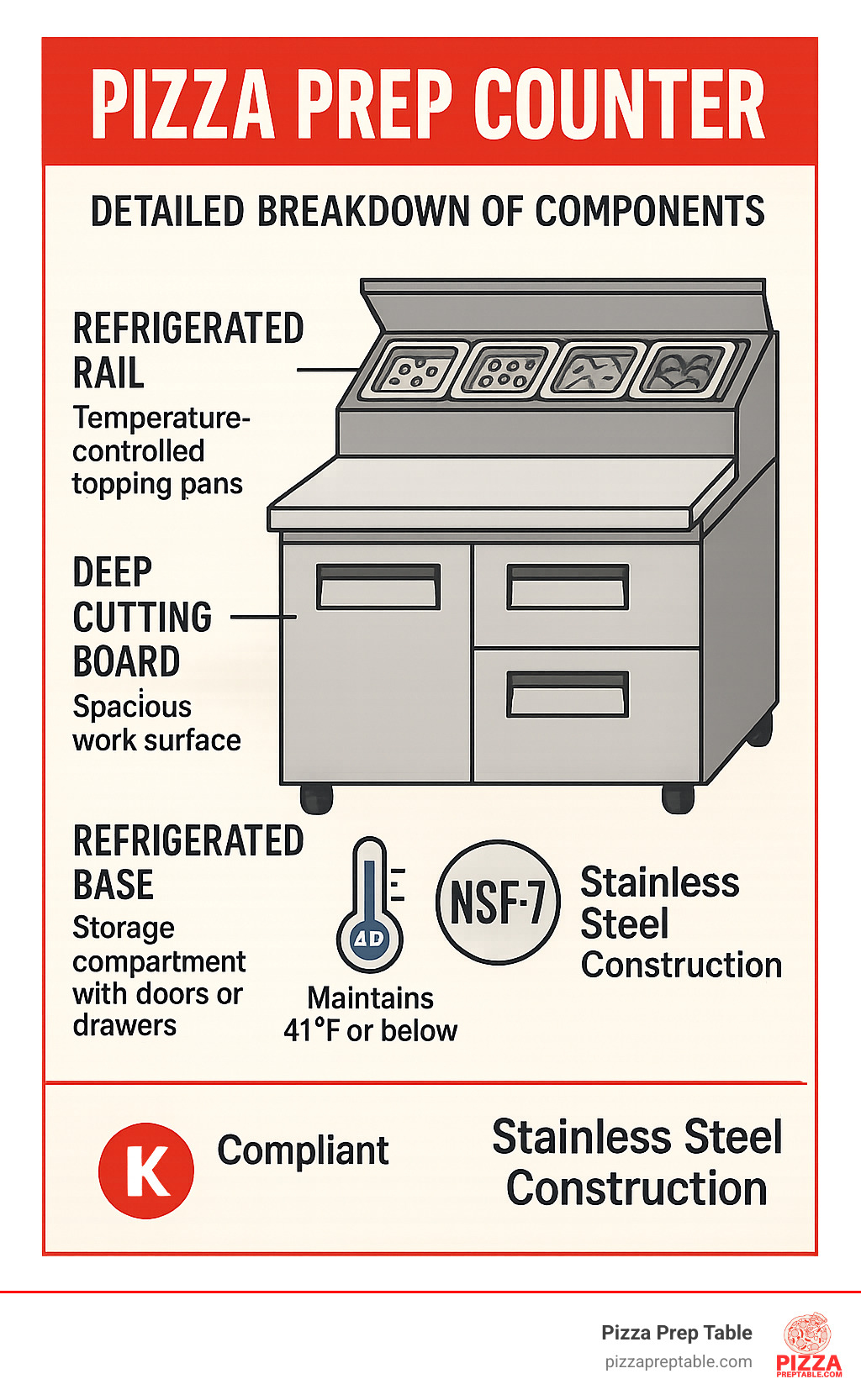

A pizza prep counter is the backbone of a successful pizzeria, combining refrigerated storage with an efficient workspace for pizza assembly. These specialized units feature a raised refrigerated rail for easy topping access and a deep cutting board that can handle even the largest pies. According to Wikipedia's overview of pizza, the dish’s global popularity continues to soar, emphasizing the need for efficient prep equipment in professional kitchens.

Key Components of a Pizza Prep Counter:

- Refrigerated Rail: Keeps toppings at safe temperatures (416F or below).

- Deep Cutting Board: A 14-19 inch workspace for large pizza preparation.

- Refrigerated Base: Bulk storage with doors or drawers.

- Temperature Controls: Digital systems for precise cooling.

- Stainless Steel Construction: Durable, easy-to-clean surfaces.

The global pizza market reached $147.5 billion in 2023 and continues to grow, putting pressure on owners to maximize efficiency while maintaining food safety. A well-designed pizza prep counter reduces preparation times and increases hourly output.

Pizza prep counters are essential for meeting commercial food safety regulations, with NSF-7 standards requiring consistent temperature control. The efficiency gains from organized ingredient storage and an optimal workspace directly impact your bottom line through faster service and reduced waste.

Pizza prep counter terminology:

Decoding the Essentials: Key Features of a High-Performance Pizza Prep Counter

A high-performance pizza prep counter is a specialized unit designed to streamline pizza-making, ensure ingredient safety, and withstand a busy commercial kitchen. The key is a powerful refrigeration system that keeps ingredients fresh and safe. The refrigerated rail must maintain a temperature of 41°F (5°C) or below, a critical rule for NSF-7 compliance. Many units feature digital temperature controls for precise adjustments, ensuring toppings are perfectly chilled.

Design features also boost efficiency and cleanliness. Self-closing doors prevent cold air from escaping, saving energy and maintaining stable temperatures. Insulated lids for the topping rail lock in cold air during slower periods, keeping ingredients fresh and preventing moisture buildup. The unit's construction is vital for food safety. Smooth, non-porous surfaces are easy to clean and sanitize, preventing bacterial growth and cross-contamination. For more on selecting the best work surface, see our guide on Cutting Edge Choices: Best Pizza Prep Table Cutting Boards.

Understanding Your Pizza Prep Counter's Refrigeration System

The cooling system is the heart of your pizza prep counter. Forced-air cooling uses fans to circulate cold air throughout the unit, ensuring even temperatures and quick recovery after door openings. Cold-wall technology integrates cooling coils into the walls, creating a "blanket of cold" around the pans. Some advanced cold-wall systems offer separate controls for the rail and base, saving energy overnight. Less common is liquid cooling, which uses chilled fluid and often eliminates the need for defrost cycles.

Regardless of the type, digital temperature controls are essential for precise management. Many modern units also feature adaptive defrost cycles that run only when needed, improving energy efficiency. You'll also find that many manufacturers now use R290 (Hydrocarbon) refrigerant, an eco-friendly option that reduces environmental impact and can lower energy costs. To explore these systems further, check out our guide on Slice and Dice in Style: Your Guide to Pizza Prep Chillers.

Materials and Construction for Durability

The materials used in a pizza prep counter impact its longevity, hygiene, and performance. Stainless steel (specifically AISI 304) is the industry standard due to its durability, resistance to corrosion, and ease of cleaning. Its non-porous surface helps prevent bacteria growth, simplifying food safety compliance.

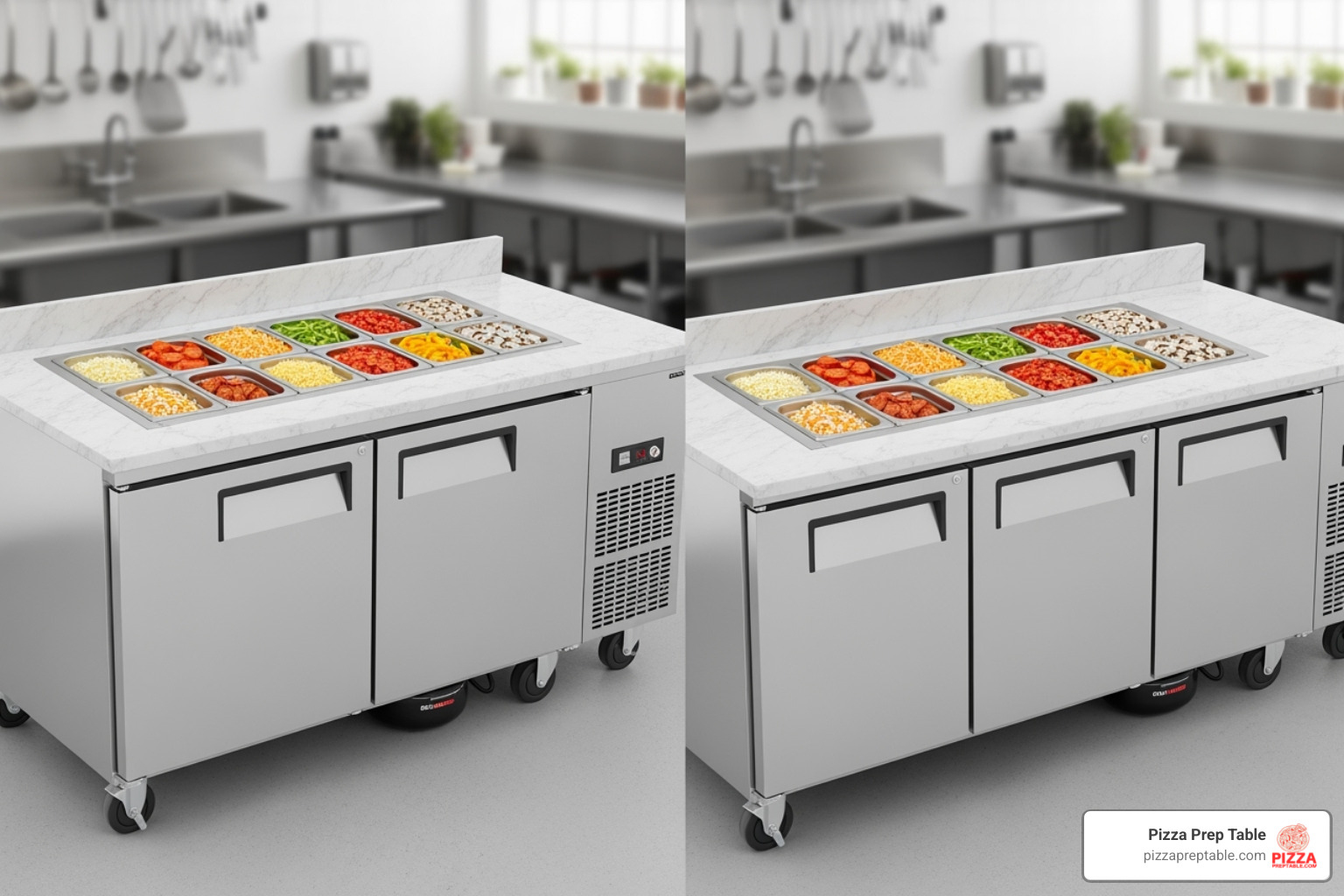

Some premium pizza prep counters feature granite or marble worktops. These materials offer a naturally cool surface ideal for working with dough. While durable and attractive, they can be more prone to chipping than stainless steel and may require special care. For more on these options, read our review: Stone Cold Deliciousness: Granite and Marble Pizza Prep Tables Reviewed.

Every pizza prep counter needs a quality cutting surface, typically a removable polyethylene cutting board designed for heavy use and easy cleaning. Smart construction details like rounded interior corners and removable magnetic door gaskets also make daily maintenance much easier, ensuring long-term hygiene.

Sizing Up Your Options: Configurations and Workflow Impact

Choosing the right size and configuration for your pizza prep counter depends on your kitchen's layout, production volume, and menu complexity. A well-chosen unit can transform your workflow from chaotic to a smooth assembly line. Your kitchen layout is critical; ensure there's enough room for the unit and for staff to move efficiently. The prep counter should be a central hub, reducing unnecessary steps and boosting productivity. For more tips, check out The Secret Sauce Behind Efficient Pizza Prep Stations.

Choosing the Right Pizza Prep Counter Size

Pizza prep counters range in width from a compact 27 inches to a sprawling 119 inches. For smaller kitchens or lower-volume operations, a unit between 46 to 60 inches wide is often sufficient. For busy, high-volume pizzerias, larger units of 70, 93, or 119 inches are necessary to accommodate more topping pans and provide ample storage, allowing multiple staff to work simultaneously. A 67-Inch Pizza Prep Table is a great mid-size option, while a 93-Inch Pizza Prep Table is ideal for high-demand kitchens.

Mega Top units offer even more pan capacity on the top rail, perfect for businesses with a wide variety of toppings. The right size depends on your menu; a diverse topping selection requires more rail capacity, while a classic menu might prioritize bulk base storage.

Doors vs. Drawers: What's Best for Your Kitchen?

The base of your pizza prep counter can have either doors or drawers, each impacting efficiency differently. Doors offer flexible bulk storage for larger items like boxes of cheese or dough trays. They accommodate various container sizes but may require more bending and reaching. You can explore options like 2-Door Pizza Prep Fridges Reviewed or larger 3-Door Pizza Prep Fridges.

Drawers, on the other hand, are designed for quick access to pre-filled pans, making it easy to replenish the topping rail during busy periods. This ergonomic design reduces staff strain and is a game-changer for high-volume operations. While they offer less flexible bulk storage, some models feature a combination of doors and drawers, providing the best of both worlds. Your choice should align with your ingredient management strategy and kitchen workflow.

Top Brands on the Menu: A Roundup of Leading Models

Choosing the right brand for your pizza prep counter is crucial. A reputable brand means quality equipment, a solid warranty, and reliable support, giving you peace of mind.

Different brands cater to various needs and budgets, but all aim for durability, stable temperatures, and user-friendly features. Here’s a quick comparison of popular models:

| Brand | Model Example | Size (Width) | Capacity (Cu. Ft.) | Refrigerant | Countertop Material | Price Range (Approx.) |

|---|---|---|---|---|---|---|

| True | TPP-AT Series | 48"-119" | 12-36 | R290 | Polyethylene | $4,000 - $12,000+ |

| Atosa | MPF8203GR | 93" | 28.4 | R290 | Polyethylene | $5,000 - $5,500 |

| Migali | C-PP93 | 93" | 26 | R134a | Polyethylene | $4,000 - $6,000 |

| Beverage-Air | DP Series | 46"-119" | 10-30+ | R290 | Polyethylene | $3,500 - $10,000+ |

Note: Prices are approximate and can vary based on features, vendor, and current market conditions.

Premium Performance: True and Turbo Air

For top-tier performance, True Manufacturing and Turbo Air are leading choices. True's TPP-AT series is known for exceptional durability, efficiency, and an angled top design for easy topping access. They also offer excellent warranties, including a five-year compressor warranty.

Turbo Air is renowned for innovation and energy savings. Their Super Deluxe Series pizza prep tables often feature a self-cleaning condenser, a system that uses a rotating brush to prevent dust buildup. This unique feature reduces maintenance and helps prevent costly repairs, extending the unit's lifespan. While these brands represent a higher initial investment, their reliability and advanced features often provide significant long-term value for busy pizzerias.

Value and Reliability: Atosa and Arctic Air

For businesses seeking a balance of quality and affordability, Atosa and Arctic Air are excellent options. Atosa has gained popularity for offering great value. Their Atosa Pizza Prep Table models, like the MPF series, often include high-quality components like Embraco compressors and Dixell digital controllers, all housed in a durable stainless steel construction.

Arctic Air provides a range of pizza prep counters that focus on essential features without the high price tag. Their units typically use an efficient air-over design for consistent temperatures and are NSF certified, making them a solid, budget-conscious choice for dependable performance. If you need a durable pizza prep counter that can handle commercial demands without breaking the bank, Atosa and Arctic Air are worth considering.

The Bottom Line: Cost, Efficiency, and Your Investment

Investing in a pizza prep counter is about more than the upfront price; it's an investment in your business's future. The right unit delivers long-term value by saving on energy, reducing maintenance, and boosting profits through improved kitchen efficiency. Keeping your equipment in top shape is also crucial; our guide on Fixing Your Pizza Prep Table Without Losing Your Toppings can help.

Understanding Price Ranges and Cost Factors

Prices for a pizza prep counter can range from $1,500 to over $12,000, influenced by several key factors. Brand reputation, size, and advanced features like self-cleaning condensers all play a role. The materials used, such as all-stainless steel construction, also impact the cost. While a used unit can save money initially, it's important to inspect it thoroughly and understand any remaining warranty. You can explore options for Used Pizza Prep Tables for Sale. Finally, a longer warranty often indicates higher quality and protects your investment.

Energy Efficiency and Maintenance Considerations

Ongoing operational costs are a significant part of the total investment. Energy efficiency is key. Look for units with ENERGY STAR certification and eco-friendly R290 (Hydrocarbon) refrigerant, which can significantly lower your utility bills. Regular maintenance is vital for longevity. Condenser cleaning is the most important task; a dirty coil makes the compressor work harder and consumes more energy. Check gaskets regularly for tears to ensure a proper seal, and follow a preventative maintenance schedule to avoid costly breakdowns. For parts and support, see our guide: Don't Lose Your Cool: Where to Find Pizza Prep Table Parts.

Making it Affordable: Financing Your Equipment

A high-quality pizza prep counter can be a significant upfront expense. That's why we at PizzaPrepTable.com believe in making these essential investments accessible. Financing allows you to get the equipment you need now without a large cash outlay, preserving your cash flow for other business needs. Flexible payment plans mean you can start generating revenue with your new equipment immediately, allowing it to pay for itself over time. We offer various leasing and financing solutions custom to different business needs. Learn more about our financing services here: More info about financing services.

Frequently Asked Questions about Pizza Prep Counters

Have questions about your pizza prep counter? Here are answers to some common inquiries to help you get the most out of your equipment.

How is a pizza prep table different from a sandwich prep table?

The main difference is the workspace design. A pizza prep counter has a much deeper cutting board, typically 14 to 19 inches, to accommodate large pizza crusts. It also features a raised, often angled, refrigerated rail that provides easy access to toppings for quick assembly. In contrast, a sandwich prep table has a shallower prep area (around 8-10 inches) and a flat rail, making it ideal for sandwiches and salads but less efficient for making pizzas.

What temperature should a pizza prep table be?

For food safety, your pizza prep counter must maintain a consistent product temperature. Both the refrigerated topping rail and the base storage area should hold temperatures at or below 41°F (5°C). This is a critical requirement to comply with NSF-7 food safety standards and prevent the growth of harmful bacteria, ensuring your ingredients are always safe for customers.

How do I clean and maintain my pizza prep counter?

Regular cleaning and maintenance are vital for hygiene, performance, and longevity. A consistent routine prevents breakdowns and keeps ingredients fresh.

- Daily: Wipe down all stainless steel surfaces, the cutting board, and the interior of the topping rail. Remove and clean all topping pans.

- Weekly: Clean the magnetic door gaskets with warm, soapy water and check for any tears or gaps to ensure a proper seal.

- Monthly: Clean the condenser coil. A dirty coil forces the unit to work harder and can lead to failure. Use a brush or vacuum to remove dust and debris unless you have a self-cleaning model.

- As Needed: Follow the manufacturer's guidelines for defrosting and ensure the drain line is clear.

- Annually: Schedule a professional preventative maintenance check-up with a certified technician to inspect the entire system and catch potential issues early.

Conclusion

It's clear that a pizza prep counter is more than just equipment; it's the command center of your pizza operation. The right unit is a smart investment that pays dividends daily through efficiency and food safety.

A streamlined workflow from a well-designed prep counter means faster service, happier customers, and higher profits. Improved food safety from consistent temperature control protects your reputation and builds customer trust with every slice.

We've covered everything from refrigeration systems and configurations to top brands like True, Turbo Air, Atosa, and Arctic Air. The key takeaway is to choose a unit that matches your specific volume, menu, and budget. The right pizza prep counter will deliver reliable performance and become the foundation for your success.

At PizzaPrepTable.com, we've seen how the right equipment can transform a kitchen. That's why we offer a wide selection and financing options to make quality equipment accessible to all businesses.

Ready to upgrade your pizza operation? Explore our full collection of pizza prep tables and find the secret ingredient for your success.