Beyond the Chill: A Deep Dive into Refrigerated Prep Table Technology

Share

Why Understanding Refrigerated Prep Table Technology Matters

A prep table with refrigeration is a commercial kitchen workhorse that combines cold storage with a workspace, keeping ingredients fresh while you assemble pizzas, sandwiches, or salads. These essential units are powered by:

- Refrigeration System: Uses a compressor and refrigerant (like R290) to hold temperatures between 33°F and 41°F.

- Storage Configuration: Features a refrigerated well or rail above the workspace, plus cabinet storage below.

- Temperature Control: Digital controls maintain consistent cooling to prevent bacterial growth.

- Design Types: Pizza prep tables have raised ingredient rails, while sandwich prep tables have recessed wells.

Understanding how your prep table with refrigeration functions is the first step toward kitchen harmony. This guide breaks down the technology behind these units—from how refrigerants create cooling to why compressor placement matters. You'll learn what separates different prep table types, what features truly matter, and how to keep your unit running efficiently.

Modern refrigerated prep tables have evolved beyond simple cooling boxes. Technologies like R290 refrigerant now deliver up to 40% energy savings while maintaining food safety standards. The right unit can transform your workflow, reduce food waste, and help you meet health code requirements with ease.

The Core of Cool: How Refrigeration Technology Works

Every prep table with refrigeration uses a refrigeration cycle to move heat from inside the unit to the outside air, keeping ingredients fresh. Understanding this process helps you appreciate why quality components matter. For a deeper dive into the science, see vapor-compression refrigeration.

The cycle starts when the compressor pressurizes refrigerant gas. This hot gas flows to the condenser, where it cools and becomes a liquid. The liquid then passes through an expansion valve, dropping its pressure and temperature. Inside the evaporator coils, this cold liquid absorbs heat from your ingredients, turning back into a gas. The gas returns to the compressor, and the cycle repeats.

This process maintains the ideal temperature, typically between 330F and 410F. Modern units use digital temperature controls for precise adjustments, keeping food safely out of the temperature danger zone where bacteria thrive.

The Refrigerant's Role in Efficiency and Sustainability

The refrigerant type affects both performance and environmental impact. While older synthetic refrigerants were common, the industry has shifted toward more sustainable options.

R290 refrigerant, a natural, non-toxic hydrocarbon, is a game-changer. As noted by the U.S. Environmental Protection Agency, it has a very low global warming potential. Brands like Migali use R290 in their products, delivering up to 40% energy savings compared to older alternatives. This means you get a smaller carbon footprint and lower energy bills without sacrificing performance. Learn more in our guide on eco-friendly options.

Understanding Compressor Power

The compressor is the engine of your refrigeration system. Quality brands like Embraco are known for reliability in demanding kitchens. Design also matters. A front-breathing design is ideal for tight spaces, as it allows you to place the unit against a wall without overheating. This prevents system failure and ensures consistent cooling.

Most units we supply are self-contained, meaning the entire system is built-in for simple plug-and-play installation. Some advanced models even include self-cleaning condensers to reduce maintenance and prevent costly repairs. For more details, check out our guide on prep fridges.

Boosting Kitchen Performance with a Prep Table with Refrigeration

A prep table with refrigeration is more than just equipment; it's a command center that upgrades how your team works. By combining cold storage with a workspace, these units deliver immediate benefits: smoother workflow, better ingredient organization, reduced food waste, and easier compliance with food safety regulations.

During a busy rush, every ingredient is chilled and within arm's reach. This eliminates trips to the walk-in cooler and prevents ingredients from warming up on the counter, resulting in efficient, consistent food preparation.

Streamlining Your Assembly Line

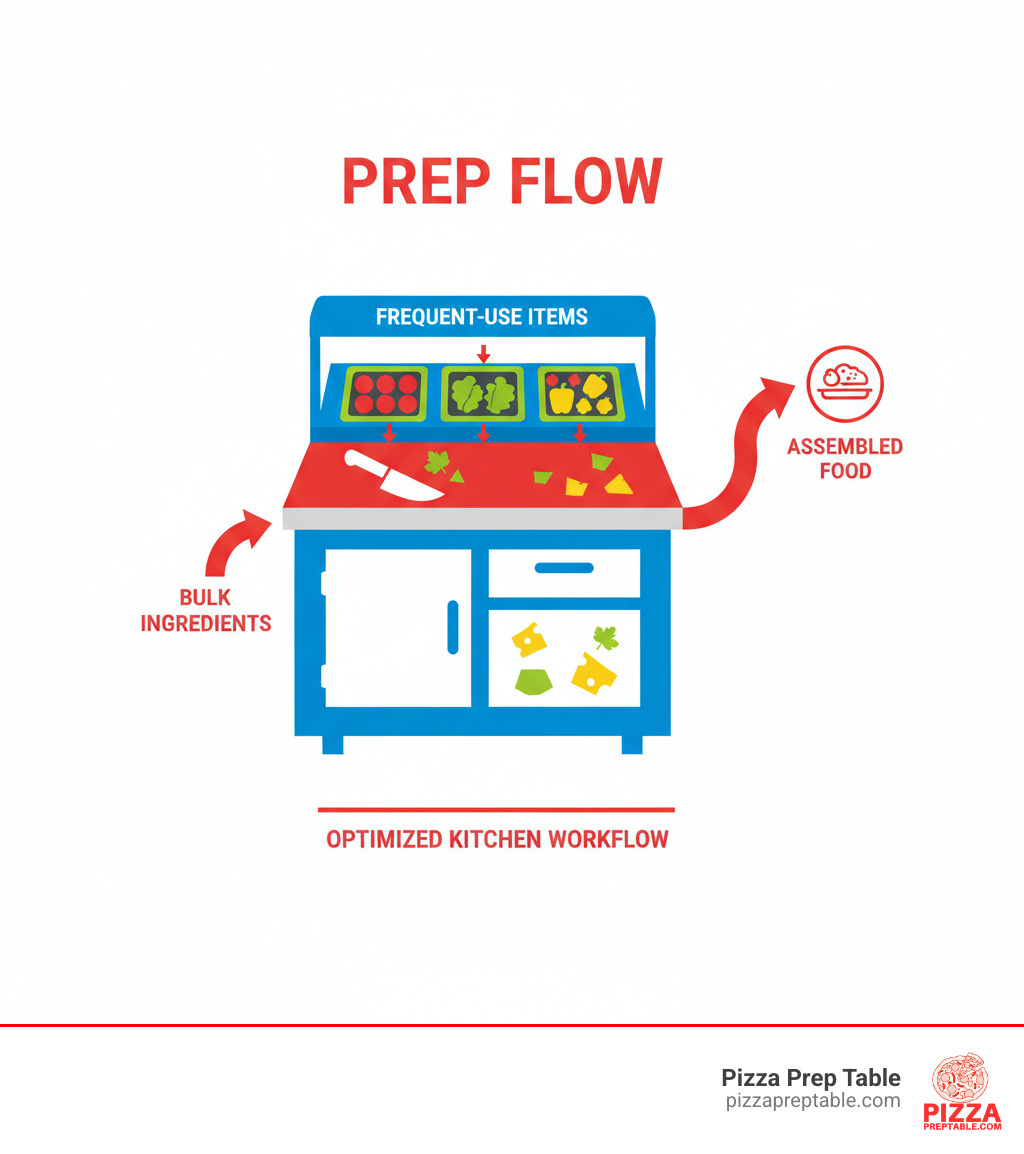

A prep table with refrigeration saves time and money by design. Your most-used ingredients sit in refrigerated wells directly above the cutting board, putting everything at your fingertips. This setup dramatically reduces prep times, leading to faster service and less physical strain on your staff.

In high-volume markets like New York City, Los Angeles, or Chicago, this efficiency is critical. An organized mise en place with cold, accessible ingredients can make or break your service. This concept is central to The Secret Sauce Behind Efficient Pizza Prep Stations. You can explore various prep table options to find the right fit for your kitchen.

Upholding Food Safety and Freshness

A prep table with refrigeration is your frontline defense against foodborne illness. It maintains the critical temperature range of 33°F to 41°F, keeping ingredients out of the danger zone and fresher for longer, which reduces food waste.

Many units we offer carry NSF, ETL, or UL certifications, proving they meet strict commercial food safety standards. This is crucial for kitchens in cities like Philadelphia, Houston, and Boston, where health codes are rigorously enforced. Design features like recessed wells and covers also help prevent cross-contamination, while refrigerated base storage keeps backup supplies at safe temperatures. This commitment to freshness is why so many businesses rely on these units, as detailed in our guide on how Freshness is Guaranteed with These Sandwich Prep Refrigerators.

How to Choose the Right Prep Table with Refrigeration

Selecting the perfect prep table with refrigeration involves matching the unit to your menu, space, and workflow. Consider the size, materials, configuration, and pan compatibility to find a prep station that helps your team thrive.

Pizza Prep Tables vs. Sandwich/Salad Prep Tables

Pizza and sandwich prep tables are built for different tasks. Choosing the wrong one can slow down your entire operation.

| Feature | Pizza Prep Tables | Sandwich/Salad Prep Tables |

|---|---|---|

| Ingredient Well | A raised rail lifts ingredients above the cutting board for easy access during assembly. | A recessed well keeps ingredient pans flush with or below the cutting surface for quick scooping. |

| Cutting Board | Deeper and wider to provide ample space for stretching dough. | Standard depth, suitable for assembling sandwiches and salads. |

| Primary Use | Ideal for high-volume pizza making. | Perfect for building sandwiches, crafting salads, and organizing smaller ingredients. |

The raised rail on a pizza prep table is engineered for speed, giving you a large workspace for dough. Sandwich prep tables use recessed wells to make layering ingredients effortless. For more details, see our guides on refrigerated sandwich prep tables and pizza prep tables.

Key Features for Your Buying Checklist

Certain features distinguish a durable, long-lasting unit from one that causes headaches.

- 304 Stainless Steel Construction: Resists corrosion from acidic ingredients like tomato sauce and is easy to sanitize. Learn more about choosing a stainless steel pizza prep table.

- Cutting Board: Look for durable, knife-friendly high-density polyethylene. A detachable board simplifies cleaning.

- Adjustable Shelving: Provides flexibility to organize the refrigerated cabinet for different container sizes.

- Caster Wheels: Make it easy to move the unit for cleaning, a major plus during health inspections.

- Self-Closing Doors: Magnetic gaskets ensure a tight seal, maintaining temperature and saving energy.

- Coved Interiors: Rounded corners in the cabinet eliminate hard-to-clean crevices where food particles can hide.

At PizzaPrepTable.com, we offer equipment from trusted brands like Migali, Atosa, Dukers, True, and Kelvinator that incorporate these essential features.

Sizing and Configuration for Your Space

Getting the size right is crucial for kitchen efficiency, from a compact NYC deli to a large Denver restaurant.

- Width: Sandwich/salad tables typically range from 27 to 72 inches. Pizza tables, needing more workspace, start at 48 inches and can go up to 93 inches. For guidance, see our article on choosing the right pizza prep table dimensions.

- Doors vs. Drawers: 2-door models are standard, while 3-door units offer more storage and compartmentalization. Drawers are great for organizing dough balls or pans.

- Undercounter Units: These compact models fit under existing counters, maximizing vertical space in smaller kitchens. Learn more about finding the perfect small prep table.

- Mega Top Tables: These offer an extra row of pan space, ideal for extensive menus or high-volume service, reducing the need for mid-rush refills.

- Pan Compatibility: Ensure the unit's divider bars can be adjusted to fit your specific mix of full-size, half-size, third-size, and sixth-size pans.

Essential Maintenance for Optimal Performance

A prep table with refrigeration is a critical investment that requires regular care to ensure longevity, efficiency, and food safety. Neglecting maintenance can lead to high energy bills, poor performance, and costly breakdowns.

Follow these essential maintenance tips:

- Clean Condenser Coils Monthly: The coils attract dust and grease, forcing the compressor to work harder. Clogged coils increase energy consumption and risk of failure. Clean them monthly, or more often in greasy environments like a busy Houston pizza kitchen.

- Inspect Door Gaskets Regularly: Torn or loose gaskets leak cold air, wasting energy and compromising food safety. Check for damage and replace worn gaskets promptly—it's an inexpensive fix with a big impact.

- Monitor Temperatures Daily: A quick check of the digital display ensures the unit is holding a safe temperature between 33°F and 41°F. This simple habit can alert you to problems before they escalate.

- Schedule Professional Servicing: Once or twice a year, have a qualified technician inspect your unit. They can calibrate components, check refrigerant levels, and catch potential issues before they become major repairs.

- Perform General Cleaning: Regularly clean all stainless steel surfaces, cutting boards, and interior compartments. Features like coved interiors make this easier, but consistent cleaning is vital for hygiene.

A well-maintained prep table with refrigeration is a reliable one. If you need help, we have resources on finding pizza prep table parts.

Frequently Asked Questions about Refrigerated Prep Tables

Here are answers to the most common questions we receive about prep tables with refrigeration.

What is the ideal temperature for a prep table with refrigeration?

The ideal temperature range is between 33°F and 41°F (0.5°C and 5°C). This keeps ingredients safely out of the "temperature danger zone," where bacteria multiply rapidly, ensuring freshness and health code compliance. Modern units with digital controls make it easy to monitor and maintain this precise range.

How do prep tables accommodate different ingredient pan sizes?

Quality prep tables with refrigeration are highly versatile. They feature adjustable or removable divider bars in the top refrigerated well. This allows you to create custom configurations to fit various standard food pan sizes, including full-size, half-size, third-size, and sixth-size pans, to match your menu's needs.

What is a "Mega Top" prep table?

A "Mega Top" prep table with refrigeration is a type of sandwich/salad prep table with increased pan capacity. It typically has an extra row of pan space (three rows instead of two), allowing you to hold more ingredients at once. This design is perfect for high-volume operations or businesses with extensive menus, as it reduces the need for mid-service restocking.

Conclusion

A prep table with refrigeration is more than an appliance; it's a strategic investment in your kitchen's efficiency, safety, and quality. Understanding the technology—from energy-saving R290 refrigerant to space-saving front-breathing compressors—empowers you to choose a unit that will serve as the backbone of your operation for years.

These units are the workhorses of successful kitchens, from New York City delis to Los Angeles pizzerias. They keep ingredients food-safe, streamline workflow, and reduce waste, which is critical in a business where efficiency is everything.

At PizzaPrepTable.com, we understand what commercial kitchens need. We help you find the right solution, whether you're a small shop in Chicago or a large restaurant in Houston. Our selection includes trusted brands like Migali, Atosa, and Dukers, all backed by financing options to fit your budget.

Choose your prep table with refrigeration wisely and maintain it properly, and it will reward you with reliable performance when you need it most.

Explore our extensive collection of commercial pizza prep tables to find the perfect model for your business.