Cool Convenience – Top Prep Tables with Built-in Fridges

Share

Why Every Commercial Kitchen Needs a Prep Table with Fridge

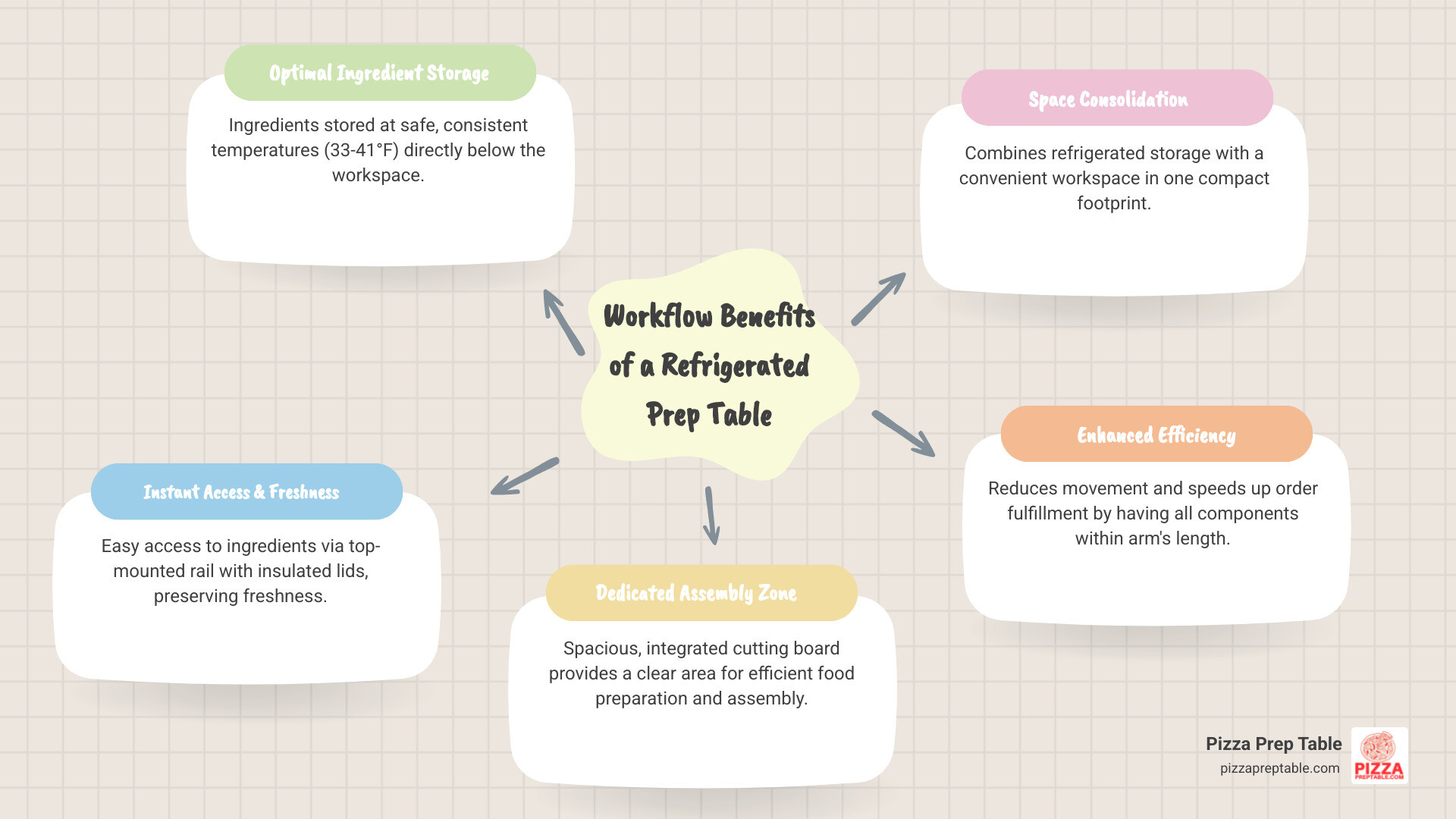

A prep table with fridge combines refrigerated storage with a convenient workspace, making it the ultimate efficiency tool for commercial kitchens. These units keep ingredients cold and fresh while providing a dedicated area for food assembly - all in one compact footprint.

Quick Answer for Buyers:

- Pizza prep tables: Raised ingredient rail, deeper cutting boards (up to 19.5"), ideal for pizza assembly

- Sandwich prep tables: Recessed ingredient well, standard 8-9" cutting boards, perfect for sandwich/salad prep

- Key sizes: 27" (small operations), 48" (medium volume), 72"+ (high volume)

- Temperature range: 33°F to 41°F for food safety compliance

- Essential features: Stainless steel construction, NSF certification, digital controls

The research shows that prep tables are considered the "back bone of food service" because they streamline operations in ways that separate refrigerators and prep surfaces simply can't match. Whether you're running a pizzeria, sandwich shop, or food truck, having ingredients at arm's length while maintaining proper temperatures can dramatically speed up order fulfillment.

I'm Sean Kearney, and my experience selling restaurant equipment has shown me how the right prep table with fridge can transform a kitchen's efficiency and profitability. From helping small cafes maximize their limited space to assisting large operations optimize their workflow, I've seen why these units are essential investments for any serious foodservice business.

The Ultimate Kitchen Upgrade: Key Benefits of a Refrigerated Prep Station

Picture this: It's your dinner rush, orders are flying in, and your kitchen staff is moving like a well-oiled machine. No one's scrambling to the walk-in cooler every few minutes, ingredients stay perfectly fresh, and orders go out faster than ever. This isn't a fantasy – it's what happens when you invest in a quality prep table with fridge.

These units aren't just another piece of equipment gathering dust in the corner. They're game-changers that transform how your kitchen operates from the ground up.

Improved workflow is the first thing you'll notice. When your most-used ingredients are right at your fingertips, your staff can assemble orders without taking a single unnecessary step. No more zigzagging across the kitchen or waiting in line at the main cooler. Everything flows naturally from ingredient to finished dish, which means faster order fulfillment and happier customers waiting for their food.

Space consolidation is where these units really shine, especially if you're working with limited square footage. A prep table with fridge combines your workspace, ingredient storage, and refrigeration into one smart package. It's like having a Swiss Army knife for your kitchen – multiple tools in one compact design that maximizes every inch of your space.

Improved food safety isn't just a nice bonus; it's essential for your business. These units maintain that critical temperature range of 33°F to 41°F, keeping ingredients in the safe zone where bacteria can't thrive. The forced-air circulation systems ensure even cooling throughout, while insulated lids minimize temperature fluctuations. Your health inspector will love you for it.

Consistent quality becomes second nature when ingredients stay at their optimal temperature and condition. No more wilted lettuce or warm cheese throwing off your carefully crafted recipes. When your ingredients maintain their integrity, your dishes do too, and that consistency keeps customers coming back.

Reduced food waste hits your bottom line in the best possible way. When ingredients are visible, organized, and properly cooled, they last longer and get used more efficiently. You'll naturally adopt better rotation practices, and spoilage becomes a thing of the past.

These benefits make refrigerated prep stations perfect for an incredible range of foodservice operations:

- Pizzerias and sandwich shops (the obvious choices)

- Delis and salad bars where fresh ingredients are everything

- Cafes and food trucks where space is at a premium

- Any establishment where speed and freshness matter

Whether you're running a busy downtown deli or a food truck that needs to maximize every square inch, a prep table with fridge adapts to your needs. Ready to see how these principles work specifically for pizza operations? Check out The Secret Sauce Behind Efficient Pizza Prep Stations for the inside scoop on pizza-specific benefits.

Pizza vs. Sandwich Prep Tables: What's the Difference?

Not all prep tables with fridges are created equal! While they might look similar at first glance, pizza and sandwich prep tables are actually designed with very different purposes in mind. It's like comparing a sports car to an SUV – both get you where you need to go, but each excels at different tasks.

The most obvious difference you'll notice is in the ingredient rail design. Pizza prep tables feature a raised ingredient rail that sits higher than the cutting board surface. This clever design makes it easy for pizza makers to reach ingredients at the back of the pans while working on large pizza surfaces. No more awkward stretching or leaning over your workspace!

Sandwich prep tables take the opposite approach with their recessed ingredient well. The food pans sit lower, nestled into the work surface itself. This creates a more streamlined workspace that's perfect for the quick, repetitive motions of sandwich and salad assembly.

But the differences don't stop there. Pizza prep tables come with much deeper cutting boards – we're talking 15 to 19.5 inches deep, sometimes even more. Some high-end models like the Omcan FMA 39592 even feature durable granite tops that are perfect for dough work. Compare that to sandwich prep tables, which typically have standard 8 to 9-inch cutting boards – just right for sandwich assembly but not designed for pizza dough stretching.

Here's how they stack up against each other:

| Feature | Pizza Prep Tables | Sandwich/Salad Prep Tables |

|---|---|---|

| Ingredient Rail | Raised, often higher than the cutting board | Recessed, pans sit lower in a well |

| Cutting Board | Much deeper (15" - 19.5"+), wider, sometimes granite | Standard depth (8" - 9.5"), typically polyethylene |

| Primary Use | Pizza assembly, dough work | Sandwich, salad, burrito, and general deli prep |

| Pan Access | Easier reach to back of pans for large surfaces | Direct, convenient access for quick assembly |

| Typical Pan Size | Often larger 1/3 or 1/2 pans, sometimes 1/6 for toppings | Commonly 1/6 or 1/9 pans |

The beauty of these specialized designs becomes clear when you see them in action. Pizza makers can efficiently stretch dough, add sauce, and grab toppings from the raised rail without missing a beat. Meanwhile, sandwich artists can quickly build orders with ingredients right at their fingertips in the recessed well.

Choosing the right style comes down to your menu. Running a pizzeria? The raised rail and expansive cutting surface of a pizza prep table with fridge will be your kitchen's MVP. Operating a deli or sub shop? The streamlined efficiency of a sandwich prep table will keep your lunch rush moving smoothly.

Want to dive deeper into each type? Check out our comprehensive guides: Commercial Pizza Prep Table and Sandwich Prep Table Refrigerator.

Key Features to Look for in a Prep Table with Fridge

Shopping for a prep table with fridge can feel overwhelming with all the options out there. But here's the thing – when you know what to look for, choosing the right unit becomes much simpler. Think of it as finding a reliable kitchen partner that'll work alongside your team day in and day out.

The three pillars of any quality prep table are durability, ergonomics, and proper certifications. Your unit needs to handle the daily grind of a busy commercial kitchen, make your staff's lives easier (not harder!), and meet all the safety standards that keep your business compliant.

Durability means your investment will last for years, not months. Commercial kitchens are tough environments with constant spills, heavy use, and rigorous cleaning schedules. A well-built prep table with fridge should shrug off this daily abuse without missing a beat.

Ergonomics might sound fancy, but it's really about common sense design. When your prep table is the right height, has easy-to-reach ingredients, and flows naturally with your kitchen's workflow, your staff works faster and more comfortably. Less strain means fewer injuries and happier employees.

Certifications like NSF International and ETL aren't just fancy stickers – they're your guarantee that the equipment meets strict safety and sanitation standards. Never compromise on these certifications, as they protect both your customers and your business.

For deeper insights into what makes a prep table truly exceptional, check out our guide on Prep Tables That Work as Hard as You Do. And if you want to see these features in action, take a look at a high-quality WESTLAKE Sandwich & Salad Prep Table as an example of quality construction.

Choosing the Right Size and Capacity for Your Prep Table with Fridge

Prep tables come in sizes ranging from compact 27-inch units perfect for food trucks to massive 119-inch models built for high-volume production. The most popular sizes fall somewhere in between – think 46", 48", 60", 67", 71", 72", and 93" widths.

Your kitchen layout is the first reality check. Measure twice, buy once! You need to account for door swings, staff walkways, and how the unit fits with your other equipment. A beautiful 93-inch prep table won't do you any good if it blocks your dishwasher access.

Menu complexity drives your pan capacity needs. A simple pizza shop might get by with 8-12 ingredient pans, while a gourmet sandwich shop with dozens of toppings could need up to 24 pans. More complex menus mean you'll want more pan slots in that top rail.

Storage needs go beyond just the visible ingredient pans. The refrigerated base underneath is where you'll store backup ingredients, larger containers, and prep work for tomorrow. Cubic feet capacities range from around 6.5 cu. ft. for smaller units up to 26 cu. ft. for the largest models. You'll also find various door and drawer configurations – from single doors to four-door setups, or drawer combinations with two, three, four, six, eight, or even nine drawers.

Want to see specific examples? Our 67-inch Pizza Prep Table hits the sweet spot for many medium-volume operations, while the 93-inch Pizza Prep Table is built for serious high-volume production.

Understanding Refrigeration Systems in a Prep Table with Fridge

The refrigeration system is literally the heart of your prep table with fridge – get this wrong, and you'll have spoiled ingredients and frustrated customers. Fortunately, modern prep tables use some pretty impressive technology to keep everything perfectly chilled.

Most quality units rely on forced-air systems that actively circulate cold air throughout the entire cabinet. This isn't just blowing cold air around randomly – it's engineered to maintain uniform temperatures from the top pan rail all the way down to items stored in the base. No more finding warm spots where ingredients spoil faster!

Digital controls have largely replaced old-school dial thermostats, and thank goodness for that. These systems let you set and monitor temperatures with precision, typically maintaining that critical 33°F to 41°F range that keeps food safe and fresh. Many units come factory preset to optimize performance right out of the box.

The real game-changer in recent years has been the switch to R290 refrigerant. Leading brands like Migali, Avantco, PeakCold, Everest, and Turbo Air have acceptd this all-natural, non-toxic hydrocarbon refrigerant. Why should you care? R290 has an Ozone Depletion Potential of zero and a Global Warming Potential of just 3 – dramatically better for the environment than older refrigerants.

But here's the kicker – R290 also delivers serious energy savings. Migali reports that their R290 units can save up to 40% in energy costs. That's money back in your pocket every month, month after month.

You'll also find other efficiency features like ECM motors in brands like Everest, which achieve rapid cooling with less energy consumption. Turbo Air's self-cleaning condenser automatically brushes daily to prevent system failure, while Everest models feature self-maintaining condensate drains that don't need electric heaters.

For more detailed guidance on refrigeration systems, don't miss our article: Doughn't Settle for Less: Choosing the Perfect Pizza Preparation Refrigerator.

Essential Design and Material Considerations

The materials and design details might seem like small stuff, but they make the difference between a prep table that lasts for years and one that becomes a maintenance headache. Let's talk about what really matters.

Stainless steel construction is non-negotiable in commercial kitchens. You'll typically find 430-type stainless steel on the exterior for its strength and professional appearance. The interior often uses higher-grade 201 or 304-type stainless steel, especially on the floor where spills and heavy use demand superior corrosion resistance. Some manufacturers use corrosion-resistant aluminum for interior liners, with specialized aluminum top interior liners designed to prevent spills from dripping into the cabinet.

The cutting board material is usually thick polyethylene – NSF-approved, durable, non-porous, and easy to clean. Most are removable for thorough cleaning or replacement. Depths vary dramatically from 8" on sandwich prep tables to 19.5" on pizza prep tables, depending on your specific needs.

Insulated lids or roll covers are absolutely crucial for maintaining consistent temperatures in the top pan rail. Whether it's insulated lids like those on PeakCold units or insulated roll covers on Migali models, these features minimize condensation and keep ingredients in the safe temperature zone even during busy rushes.

Self-closing doors with 90° stay-open features might sound like a small detail, but they're genius in practice. Doors automatically close to prevent temperature loss, while the 90-degree hold-open feature makes loading and unloading much easier. Recessed door handles add to the sleek design and prevent snagging on aprons or equipment.

Heavy-duty casters (often 5 inches) with locks are essential for easy cleaning underneath and repositioning when needed. Some models like the Avantco SS-PT-27-HC feature 2.5-inch casters that bring the unit to ADA-compliant working height.

Don't overlook the shelving – look for sturdy, epoxy-coated steel wire shelves that can handle significant weight (typically 88-90 lbs per shelf) while allowing proper air circulation. Foamed-in-place polyurethane insulation rounds out the package, providing optimal temperature retention and energy efficiency.

For more insights on selecting equipment with the right design features, read our comprehensive guide: Table Manners: Picking the Perfect Kitchen Prepping Table.

Frequently Asked Questions about Refrigerated Prep Tables

Running a commercial kitchen brings its fair share of questions, and we get it! When you're investing in equipment that'll be the backbone of your operation, you want to know everything. Here are the most common questions we hear about refrigerated prep tables, answered with the kind of straight talk that comes from years in the trenches.

How do you maintain a prep table with a fridge for longevity?

Think of your prep table with fridge like a reliable workhorse - treat it well, and it'll serve you faithfully for years. The good news? Maintenance isn't rocket science, just consistent care.

Regular cleaning is your best friend here. Every day, wipe down that stainless steel exterior and interior until it gleams. Pull out the cutting board and give it a thorough scrub, along with all those food pans. Some folks mention their units "tend to condensate a lot and needed to be cleaned more than once a day" - that's just the nature of the beast in busy kitchens. A little extra wiping prevents moisture buildup and keeps everything running smoothly.

Condenser coil maintenance is where the magic happens - literally. This is your refrigeration system's powerhouse, and keeping it clean ensures everything runs efficiently. The beauty of modern units is that many, like those from Everest, feature easily accessible, slide-out condensers. Turbo Air even has a "self-cleaning condenser" that automatically brushes daily to prevent system failure. Pretty neat, right? When coils get dirty, your compressor works overtime, driving up energy costs and potentially shortening its life.

Don't forget those gasket checks either. Those magnetic door gaskets create the tight seal that keeps cold air where it belongs. Give them a quick inspection regularly for cracks, tears, or wear. Most are designed for tool-free removal, so replacing them when needed is straightforward. A poor seal means your unit works harder and costs more to run.

Finally, practice proper loading. Yes, your prep table can handle a lot, but overstuffing the refrigerated base or cramming too much into the top pan rail blocks airflow. This leads to inconsistent temperatures and makes your unit work harder than necessary.

Need more detailed guidance on keeping your equipment in top shape? Check out our comprehensive guide: Don't Lose Your Cool: Where to Find Pizza Prep Table Parts.

What are Mega Top prep tables?

Mega Top prep tables are like the overachiever cousin of standard sandwich or salad prep tables. While a regular 48-inch sandwich prep table with fridge might hold 8-12 food pans in its top rail, a Mega Top version of the same width can typically accommodate 18 (1/6 size, 6" deep) food pans. That's a game-changer for busy kitchens!

The secret sauce is that third row of pans - or simply a much wider pan area that gives you dramatically increased pan capacity right at your fingertips. Think of it as having your entire ingredient arsenal within arm's reach.

This design shines when you have extensive menus. Custom sandwich shops, build-your-own salad bars, or complex burger joints with dozens of toppings benefit enormously from this setup. Instead of constantly restocking from the refrigerated base below, everything your staff needs is right there on top.

The result? Streamlined prep that keeps your kitchen humming even during the lunch rush. Customer reviews consistently praise the "lots of storage space" and "good amount of space for different toppings" that Mega Top units provide. Yes, they take up slightly more counter space due to the wider top, but the efficiency gains often make it worthwhile for high-volume operations.

Want to see this concept in action? Take a look at our insights on the Atosa Pizza Prep Table for a real-world example.

What temperature should a refrigerated prep table be?

Getting the temperature right in your prep table with fridge isn't just good practice - it's the law, and for excellent reason. The magic number range is 33°F to 41°F (0.5°C to 5°C), and this isn't negotiable.

Why these specific food safe temperatures? This range keeps your ingredients safely out of the "danger zone" (41°F to 135°F), where harmful bacteria throw their own little multiplication party. Nobody wants uninvited guests like that!

Modern prep tables make hitting this target easy with digital thermostats and digital controls that let you set and monitor temperatures precisely. Many units come with bright LED displays that make checking temperatures a breeze, and most are factory preset to maintain this optimal range right out of the box.

Staying within this temperature range ensures food code compliance with health departments and regulatory bodies like the NSF (National Sanitation Foundation). These folks don't mess around when it comes to public health and safety.

Beyond legal requirements, proper temperatures keep your ingredients tasting their best. Consistent cold storage preserves texture, flavor, and nutritional value while significantly extending shelf life. That means less waste, better-tasting food, and more money staying in your pocket.

Keep a close eye on those temperatures, especially if your kitchen runs hot or humid. Your equipment works hard, but it's not magic - it needs your attention to perform at its best.

For more insights on keeping everything perfectly chilled and your customers happy, dive into our guide: Prep Sandwich Refrigerators That Keep Your Ingredients Fresh and Your Customers Happy.

Conclusion: Find Your Perfect Prep Partner

After diving deep into prep table with fridge units, one thing becomes crystal clear: these aren't just pieces of equipment sitting in your kitchen. They're your secret weapon for creating a smoother, safer, and more profitable operation.

Think about it - we've covered how these units boost your efficiency by keeping everything within arm's reach, consolidate your precious kitchen space, and maintain that crucial food safety that keeps customers coming back. Whether you're flipping dough for New York-style pies or crafting artisanal sandwiches, the right prep table with fridge transforms chaos into choreography.

The beauty lies in their versatility. From the raised rails of pizza prep tables that make topping assembly a breeze, to the recessed wells of sandwich prep tables that speed up order fulfillment - there's a perfect match for every kitchen's personality and needs.

At PizzaPrepTable.com, we get it. Every kitchen tells a different story, faces unique challenges, and serves different communities. That's why we've built our reputation on offering a wide selection of commercial pizza prep tables, restaurant equipment, and kitchen appliances that work for everyone - from the cozy neighborhood pizzeria to the busy food truck to the high-volume operation feeding hundreds daily.

We're not just about selling equipment; we're about creating partnerships. Our financing options mean you don't have to choose between cash flow and efficiency. Whether you're in Chicago's deep-dish scene, serving up fresh ingredients in California, or keeping Austin weird with creative combinations, we help businesses across the country upgrade their operations without breaking the bank.

The bottom line? Investing in quality refrigerated prep equipment means fresher ingredients, faster service, and happier customers - the trifecta of foodservice success. When your ingredients stay perfectly chilled and your workflow runs like clockwork, everyone wins.

Ready to slice your prep time and boost your kitchen's performance? Your perfect prep partner is waiting.

Explore our collection of the best pizza prep tables to slice your prep time.