Doughn't Settle: The Ultimate Pizza Make Table Guide

Share

Why Every Successful Pizzeria Needs a Professional Pizza Make Table

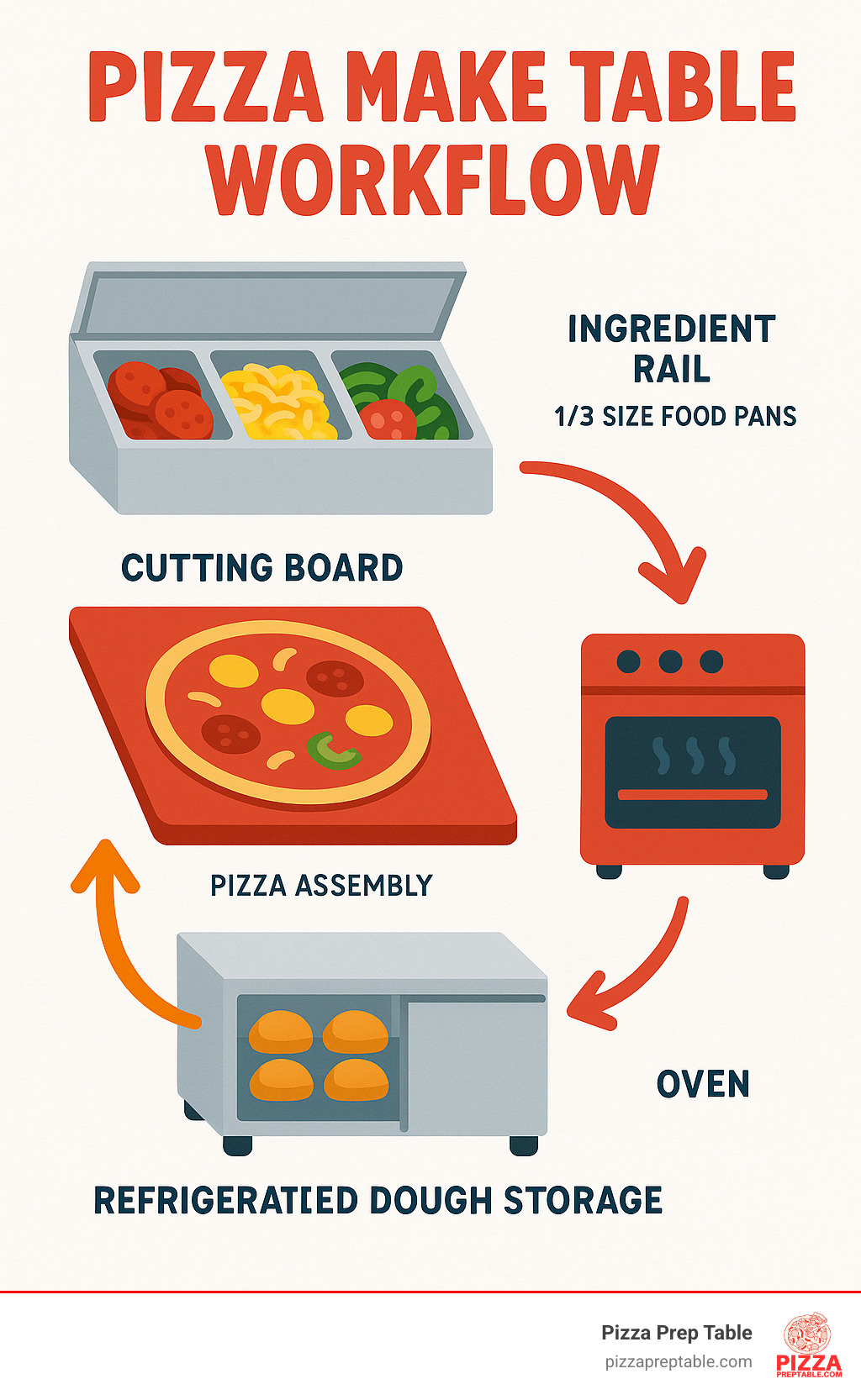

A pizza make table is a specialized commercial refrigeration unit combining a refrigerated base, a raised ingredient rail, and a cutting board, all designed for efficient pizza assembly. These essential workstations keep ingredients at safe temperatures (33°F to 41°F) while providing an organized space for consistent pizza preparation.

Quick Answer for Pizza Make Table Buyers:

- Purpose: Refrigerated prep station for pizza assembly

- Key Features: Cold storage below, ingredient rail on top, cutting board surface

- Temperature Range: 33°F to 41°F for food safety

- Standard Sizes: 44", 67", 93" widths available

- Pan Capacity: 6-12 pans depending on size

- Price Range: $1,599 - $20,453 depending on brand and features

Every successful pizzeria needs to prepare high-quality pizzas quickly while meeting food safety standards. The solution is a professional pizza make table, which streamlines workflow and keeps ingredients fresh. Unlike standard prep tables, they feature deeper cutting boards (typically 19½ inches) for large pizzas and raised ingredient rails to keep toppings contained. The refrigerated base stores dough and backups, while the top rail provides easy access to frequently used toppings.

I'm Sean Kearney, and with years of experience in restaurant equipment, I've seen how the right pizza make table can transform a struggling kitchen into a thriving one.

Terms related to pizza make table:

Anatomy of a Pizza Prep Table: More Than Just a Counter

A master pizzaiolo's speed and precision during a dinner rush aren't just about skill; they're about having the right pizza make table that harmonizes the entire process. This isn't just a counter; it's an engineered workstation, the command center of your pizza operation.

It integrates a refrigerated cabinet for fresh ingredients, a raised ingredient rail for toppings, and a deep cutting board for ample workspace—a design perfected over decades in real pizzerias.

Key Features and Components

Let's break down the essential components of a pizza make table.

The refrigerated base provides crucial storage for backup ingredients and dough balls, keeping them fresh and safe between 33°F and 41°F. Above it, the ingredient rail (or "mega top") holds your most-used toppings in 1/3 size food pans, keeping them within easy reach.

Insulated lids are crucial for maintaining temperature during slower periods, reducing strain on your refrigeration system and lowering energy costs. The cutting board, at a specialized 19½-inch depth, provides the necessary space for stretching large pizza dough.

Stainless steel construction ensures durability and easy sanitation, which health inspectors appreciate. A digital controller provides at-a-glance temperature monitoring, and casters allow for easy mobility during deep cleaning.

As the secret to great pizza often lies in the details, having the right setup makes all the difference. For more insights on optimizing your workspace, check out more info about topping stations.

The Benefits of a Dedicated Prep Station

A dedicated pizza prep station offers significant advantages.

Improved workflow: With everything within arm's reach, your team avoids constant trips to the walk-in cooler, creating a smooth, efficient rhythm even on the busiest nights.

Consistent quality: When ingredients are held at the proper temperature and organized consistently, every pizza meets the same high standard, building customer loyalty.

Food safety: Maintaining the safe temperature zone (33°F to 41°F) is your first line of defense against foodborne illness, protecting your customers and your reputation.

Reduced food waste: Properly chilled ingredients last longer, which means less spoilage and more profit.

Increased speed: A streamlined process allows your team to work faster during peak hours, serving more customers and increasing revenue.

We know that prep tables work as hard as you do, and the right pizza make table becomes an extension of your team. For more insights on maximizing efficiency, explore The Secret Sauce Behind Efficient Pizza Prep Stations.

Choosing the Right Pizza Make Table for Your Pizzeria

Choosing the right pizza make table requires considering your pizzeria's unique needs. While there's no one-size-fits-all solution, key factors can guide your decision.

Before buying, evaluate your kitchen space—measure carefully to ensure a good fit. Your production volume dictates the size and capacity you'll need to handle rushes. A diverse menu variety with many toppings requires more pan space than a menu with a few classic pies. Finally, consider your budget. We offer financing options at PizzaPrepTable.com to help you afford the quality equipment you need.

For a comprehensive look, our guide on choosing the perfect pizza preparation refrigerator walks you through every detail.

Sizing and Dimensions

Finding the right size is about balancing workspace with your kitchen's footprint.

Width options range from 44 to 119 inches. 44-inch tables are compact and ideal for smaller spots. The 67 Inch Pizza Prep Table is a popular choice, offering a balance of generous workspace and pan capacity for most kitchens. For high-volume operations, the 93 Inch Pizza Prep Table is a powerhouse with extensive prep and storage space.

Cutting board depth is typically 19½ inches to accommodate large pizzas, while the standard height of 32 to 36 inches is ergonomically designed to reduce back strain. Also, consider the compressor location (side or rear-mounted) and ensure adequate clearance for airflow.

Pizza Prep vs. Sandwich Prep Tables

Many pizzeria owners mistakenly interchange pizza and sandwich prep tables. Though they look similar, they are designed for different tasks.

| Feature | Pizza Prep Table | Sandwich/Salad Prep Table |

|---|---|---|

| Cutting Board | Wider and deeper (19½ inches) for large pizzas | Typically shallower and narrower |

| Pan Capacity | Accommodates 1/3 sized food pans | Generally holds 1/6 sized food pans |

| Rail Design | Designed to prevent toppings from falling off large pizzas | May include additional dividers for smaller ingredients |

| Food Density | Suited for denser, larger food products (cheese, meats) | Ideal for lower density toppings (veggies, condiments) |

| Primary Use | Pizza assembly | Sandwich, salad, or deli preparation |

The key differences are the cutting board size, which provides room to work with large doughs, and the pan capacity, which uses larger 1/3 size pans for high-volume pizza toppings. The rail design is also optimized for pizza assembly.

If you're curious about the sandwich side of things, you can learn about sandwich prep tables and see exactly why they're built differently.

Selecting Your Pan Capacity

Choosing the right pan capacity ensures your toppings are organized and accessible. 1/3 size food pans are standard for pizza prep tables, as they hold larger quantities of ingredients like cheese and pepperoni.

Your topping variety is the main factor. A complex menu needs more pans than a simple one. Consider your most popular toppings; you may want deeper pans for high-demand items like mozzarella.

Common pan configurations include:

- 6-pan units: Ideal for focused operations or smaller pizzerias.

- 8-pan units: A versatile choice for mid-sized pizzerias with varied menus.

- 12-pan units or more: Necessary for high-volume establishments with many topping options.

The key is to match pan capacity to your actual production needs.

Under the Hood: Refrigeration Systems & Temperature Control

The heart of any pizza make table beats in its refrigeration system. Think of it as the silent guardian that keeps your ingredients fresh, safe, and ready for the dinner rush. Without a reliable cooling system, even the most beautiful prep table becomes just an expensive counter.

Every pizza make table is engineered to maintain that sweet spot between 33°F and 41°F. This might seem like a narrow window, but it's actually the perfect balance - cold enough to keep bacteria at bay, yet not so cold that your ingredients freeze or lose their texture. Your mozzarella stays perfectly meltable, your vegetables remain crisp, and your dough maintains its ideal consistency.

Here's something that might surprise you: many modern units are switching to R290 refrigerant. This eco-friendly hydrocarbon refrigerant isn't just better for our planet - it can slash your energy costs by up to 40%. When you're running a pizzeria, every dollar saved on utilities goes straight to your bottom line.

The technology behind these systems has come a long way. We've seen units from brands like Migali that use advanced cooling methods to ensure every corner of your ingredient rail stays at the perfect temperature. No more worrying about hot spots or uneven cooling that could compromise food safety.

To explore options that keep your ingredients perfectly chilled, check out our selection of top Dukers pizza prep tables.

Types of Refrigeration Systems

Not all cooling systems are created equal, and understanding the differences can help you choose the right pizza make table for your operation. Each system has its own personality and benefits.

Air cooled systems are the workhorses of the industry. They're straightforward, reliable, and get the job done by circulating cold air from the refrigerated base up into the ingredient rail. Think of it like a gentle breeze that keeps everything chilled. The main thing to watch with these systems is keeping those lids closed when possible - every time you lift the lid, you're letting that precious cold air escape.

Cold wall systems take a different approach entirely. Instead of moving air around, they embed refrigerant lines directly into the walls of the ingredient rail. This creates what we call conductive cooling - the pans get chilled through direct contact. It's like having a cold plate that keeps everything at the perfect temperature. These systems often give you more precise temperature control and can handle frequent lid openings better than air-cooled units.

Glycol systems represent the premium end of cooling technology. They run a special cold fluid through the divider rails, creating consistent cooling without the need for fans or vents in the pan area. This means you can use deeper food pans and don't have to worry about airflow issues. Plus, they rarely need defrosting, which means less downtime for your operation.

Some high-end units feature forced air pan rail systems with specialized ducting. These ensure that every single pan gets the same amount of cold air, eliminating those frustrating hot spots that can compromise food safety. It's like having a personal air conditioning system for each of your ingredients.

Understanding these systems can help you make an informed decision when you slice and dice in style with your guide to pizza prep chillers.

Why Temperature Matters

Temperature control in your pizza make table isn't just about keeping things cold - it's about protecting your business, your customers, and your reputation. When we talk about that critical 33°F to 41°F range, we're talking about the difference between success and disaster.

Ingredient freshness depends entirely on consistent temperatures. Your pizza dough needs to stay at the right temperature to maintain its texture and rise properly. Cheese that gets too warm starts to sweat and clump together, making it harder to spread evenly. Vegetables lose their crispness, and meats can develop off-flavors. Every degree matters when you're trying to create the perfect pizza.

The science behind preventing bacteria growth is simple but critical. Between 41°F and 135°F lies what food safety experts call the "Danger Zone" - temperatures where harmful bacteria multiply faster than you can say "extra pepperoni." By keeping your ingredients below 41°F, your pizza make table acts as your first line of defense against foodborne illness.

NSF standards aren't just bureaucratic red tape - they're your assurance that the equipment you're buying has been designed with food safety in mind. These standards cover everything from the materials used in construction to the way air flows through the cooling system. When you see that NSF certification, you know you're getting equipment that meets the highest safety standards.

Perhaps most importantly for your bottom line, consistent temperatures lead to consistent pizzas. When your ingredients are always at the right temperature, your staff can work more efficiently, your pizzas taste the same every time, and your customers keep coming back. That's the kind of reliability that builds a successful pizzeria.

For dependable temperature control, consider looking into Atosa models, known for their robust refrigeration systems that keep performing day after day.

Best Practices for Cleaning and Maintenance

Your pizza make table is a workhorse that needs proper care to perform its best. A little daily attention and regular maintenance can prevent costly repairs and extend the life of your unit.

While we can help you find pizza prep table parts, preventative maintenance is always the best strategy. For those with home setups, compact residential prep stations also benefit from regular care and the same disciplined cleaning routine used in commercial kitchens.

Daily Cleaning Checklist

Incorporate these simple steps into your daily closing routine to keep your unit in top shape:

- Wipe surfaces: Clean interior and exterior stainless steel surfaces with a mild detergent and soft cloth to remove food debris and prevent buildup.

- Clean the cutting board: Remove the board for a thorough wash with hot, soapy water, then sanitize and air dry. This extends its life and ensures a safe work surface.

- Wash food pans: Empty all pans from the ingredient rail and run them through your standard wash, rinse, and sanitize cycle.

- Check gaskets: Wipe door and lid gaskets to remove food particles that can prevent a tight seal, which causes the compressor to work harder.

- Sanitize high-touch areas: Clean handles, lids, and digital controls.

Maintaining Your Pizza Make Table for Longevity

Perform these deeper maintenance tasks regularly to ensure long-term performance.

- Clean condenser coils monthly: Dust and grime buildup forces the compressor to work harder. A quick cleaning with a brush or vacuum prevents costly repairs and improves efficiency.

- Inspect moving parts: Check door hinges and latches for loose screws or wear. A drop of food-grade lubricant can keep them operating smoothly.

- Ensure proper airflow: Keep air vents around the compressor clear of obstructions. Blocked vents can cause the system to overheat.

- Monitor the temperature display: If the unit struggles to maintain temperature, it's a sign of a problem that needs immediate attention.

- Replace gaskets as needed: Worn or cracked gaskets leak cold air and increase energy costs. Replace them to maintain an efficient seal.

A well-maintained pizza make table ensures consistent temperatures, safe food, and reliable operation for years to come.

Frequently Asked Questions about Pizza Prep Tables

Here are answers to the most common questions I hear from pizzeria owners.

What is the main difference between a pizza prep table and a sandwich prep table?

The main differences are the cutting board size and pan configuration. Pizza prep tables have deeper cutting boards (around 19½ inches) to accommodate large pizzas and use larger 1/3 size food pans for high-volume toppings. Sandwich prep tables have shallower boards and use smaller 1/6 size pans for condiments and lighter ingredients.

What is the ideal temperature for a pizza make table?

The ideal temperature is between 33°F and 41°F. This range is crucial for food safety, preventing bacteria growth (which thrives above 41°F) while keeping ingredients from freezing. Regularly monitor the digital display to ensure the unit maintains this critical temperature zone.

How do I choose the right size pizza prep table for my kitchen?

To choose the right size, consider four key factors:

- Kitchen Space: Measure your available area, including doorways and clearance for compressor airflow.

- Production Volume: A low-volume spot might need a 44-inch table, while a high-volume pizzeria may need a 67-inch or 93-inch model.

- Menu Variety: More toppings require more pan capacity, which means a wider table.

- Budget: Balance upfront cost with the long-term efficiency gains. We offer financing options at PizzaPrepTable.com to help you get the right equipment.

The right choice depends on a careful analysis of your space, volume, menu, and budget.

Conclusion: The Foundation of a Great Pizzeria

A pizza make table is more than just equipment; it's the heart of your pizzeria and the foundation of your success. It is the key to the efficiency, quality, and consistency that turn a good pizzeria into a great one. By keeping ingredients organized, fresh, and within reach, it transforms kitchen chaos into a symphony of pizza creation.

Investing in the right pizza make table is an investment in your pizzeria's future. Every dollar spent on quality equipment pays dividends through faster service, reduced waste, and consistently delicious pizzas that keep customers coming back.

At PizzaPrepTable.com, we understand what pizzeria owners need. We are partners in your success, offering a wide selection of tables and flexible financing options for businesses of all sizes. Our goal is to help you get the top-tier equipment that can transform your operation.

Pizzeria owners across the nation trust us to deliver equipment that keeps their operations running smoothly. From New York City and Chicago to Austin and Seattle, and in cities like Philadelphia, Las Vegas, Houston, San Diego, Phoenix, San Antonio, San Francisco, Dallas, Columbus, Denver, Charlotte, Atlanta, Indianapolis, Washington D.C., and Baltimore, we're here to support your success.

Ready to build a stronger foundation for your business? Explore our complete collection of pizza prep tables and find how the right equipment can lift your pizzeria.