Smart Buys: How to Score a Great Used Sandwich Prep Table

Share

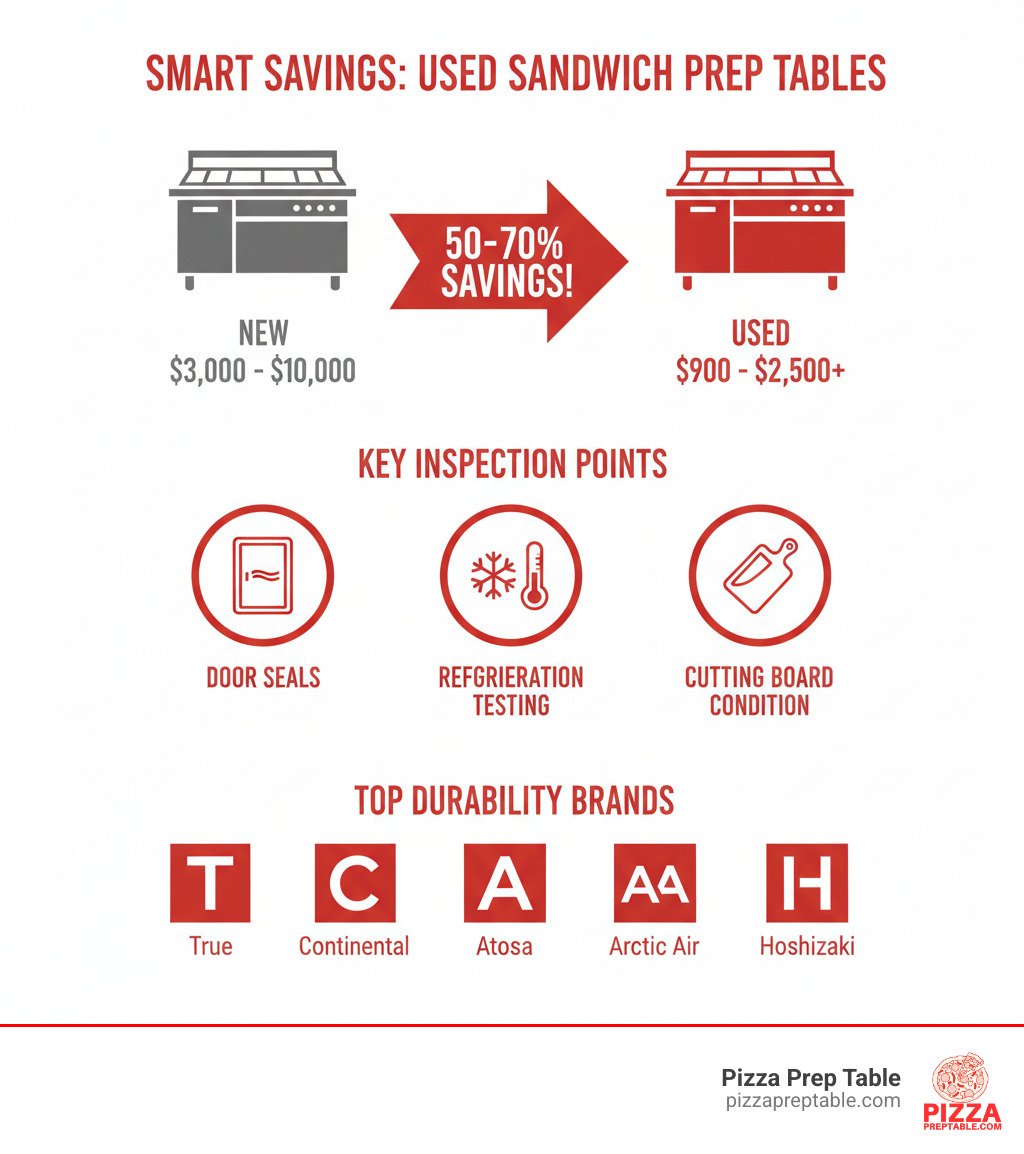

Why a Used Sandwich Station is Your Best Kitchen Investment

A used sandwich station can save you thousands while delivering the same performance as a new unit. Based on market data, used sandwich prep tables range from $900 to over $2,500, offering significant savings compared to new models that can cost $3,000 to $10,000.

Quick buying checklist for used sandwich stations:

- Price range: $900 - $2,500+ depending on size and brand

- Top brands: True, Continental, Atosa, Arctic Air, Hoshizaki

- Key sizes: 27", 36", 48", 60", 72" widths available

- Must-check features: Working refrigeration, door seals, cutting board condition

- Best sources: eBay, restaurant equipment auctions, local dealers

For restaurant owners starting out or expanding on a budget, buying used commercial kitchen equipment makes perfect financial sense. You can often find barely used units from restaurant closures or upgrades - sometimes saving 50-70% off retail prices.

The used sandwich prep table market is growing as more businesses look for cost-effective solutions. Popular models include mega-top units (with extra pan storage on top) and standard refrigerated bases with cutting boards.

As Sean Kearney, I've helped countless restaurant owners find quality used sandwich station equipment that fits their budget and space needs. My background in sales and deep understanding of the foodservice industry has taught me that the right used equipment can be just as reliable as new - if you know what to look for.

The Savvy Chef's Secret: Why a Used Sandwich Prep Table is a Smart Investment

Here's something most restaurant consultants won't tell you: some of the most successful pizzeria owners I know started with used sandwich stations. It's not about cutting corners - it's about being smart with your money.

Let's talk numbers first. When you buy a used sandwich station for $1,200 instead of spending $4,500 on a new one, you've just freed up $3,300. That money can go toward better ingredients, marketing your grand opening, or keeping a cushion for those inevitable first-year surprises. Our Restaurant Startup Costs Breakdown shows just how quickly these expenses add up.

The math gets even better when you consider faster ROI. If your new prep table needs to generate an extra $3,300 in profit to pay for itself versus a used one, that could take months longer to achieve. In the restaurant business, cash flow is king, and every month matters.

Here's what surprised me when I first got into restaurant equipment: proven reliability often beats shiny and new. A five-year-old True or Continental prep table that's been humming along in a busy kitchen? That's actually a better bet than an untested unit from a budget brand. These commercial workhorses are built to handle decades of service, and if they've survived their first few years, they'll likely keep going strong.

Your customers might not care about your eco-friendly choice, but you should feel good about it anyway. Every time you buy used equipment, you're keeping perfectly good machinery out of landfills and reducing demand for new manufacturing. It's a small way to do right by the planet while doing right by your wallet.

But my favorite advantage? Immediate availability. I've seen too many restaurant openings delayed because someone was waiting for a factory order. When you buy local or from an auction, you can often pick up your prep table the same week. No shipping delays, no damaged freight claims - just load it up and get cooking.

The bottom line is simple: a quality used sandwich station lets you start strong financially, which gives you more room to succeed in everything else.

Your Buying Guide: What to Look For in a Used Sandwich Prep Table

Shopping for a used sandwich station can be simple if you know what to look for. Commercial kitchen equipment is built to last, so a well-chosen used unit can serve you for years. This guide will help you choose the right unit for your needs.

Size, Capacity, and Type

Choosing the right size is crucial. Too small means constant restocking during busy periods, while too large wastes valuable kitchen space and energy.

- Standard prep tables are workhorses with a refrigerated base and a top rail for ingredient pans, ideal for most sandwich shops.

- Mega top models are for high-volume operations, offering up to 50% more pan capacity to speed up service.

- Countertop versions are compact stations for keeping ingredients cold on existing work tables, perfect for small spaces.

The number of doors determines your backup storage. A 27 Inch Sandwich Prep Table has one door for tight spaces, a 48 Inch Sandwich Prep Table has two for mid-sized operations, and a 60 Inch Sandwich Prep Table offers three doors for maximum storage.

Pan capacity can range from 6 pans on small units to over 20 on large mega tops. More pans allow for more variety. Before buying, measure your kitchen space carefully, considering workflow and outlet locations. Our guide on Finding the Perfect Small Prep Table for Your Space can help.

Top Brands Known for Durability

The brand name on a used sandwich station indicates its quality. Some manufacturers have a reputation for decades of reliable service.

| Brand | Durability | Common Features | Used Price Point (Approx.) |

|---|---|---|---|

| True Manufacturing | Robust construction, long lifespan | Stainless steel, forced-air refrigeration, energy-efficient, self-contained systems | $1,200 - $2,500+ |

| Continental Refrigerator | High-quality components, reliable performance | Stainless steel, heavy-duty shelving, oversized refrigeration systems for consistency | $1,100 - $2,300+ |

| Atosa | Good value, solid build for the price | Stainless steel, Dixell digital controllers, pre-installed casters | $900 - $1,800+ |

True Manufacturing units are built to run for 15+ years, making a 5-year-old model a solid investment. Continental Refrigerator focuses on consistent temperature control, even during busy rushes. Atosa offers excellent value and reliability without breaking the bank. Our Atosa Pizza Prep Table guide has more details.

Other quality brands to look for include Arctic Air, Hoshizaki, Turbo Air, Everest, and Kratos.

Key Features and Price Range

Key features can make or break your experience with a used sandwich station.

- The refrigeration system is critical. Look for self-contained, forced-air systems that maintain 33°F to 41°F for food safety.

- Stainless steel construction is non-negotiable for durability and easy cleaning.

- The cutting board should be polyethylene and free of deep grooves that can harbor bacteria.

- Casters for mobility are incredibly useful for cleaning and rearranging your kitchen.

- Digital temperature controls provide precise monitoring for food safety.

Price ranges for used units are typically $900 to $2,500+, depending on size, brand, and condition. Even at the high end, you're saving thousands compared to new. For more on refrigeration, see our Refrigerated Sandwich Prep Table page.

Buying a used sandwich station is about balancing your needs, space, and budget. Take your time and ask questions to find the perfect unit.

Where to Find and How to Buy a Used Sandwich Prep Table

Finding the perfect used sandwich station is like a treasure hunt, and the market for used commercial kitchen equipment is thriving. Here’s where to look.

Online marketplaces have changed the game. eBay offers a massive selection of used prep tables from top brands, with filters for size, condition, and buying format. Specialized sites like Bid-on-Equipment focus exclusively on commercial kitchen gear, often with detailed descriptions from knowledgeable sellers. For local finds, Facebook Marketplace, dedicated restaurant equipment groups, and Craigslist are goldmines. They allow you to inspect items in person and avoid shipping costs.

Restaurant auctions, especially from liquidations, can offer incredible deals. Online auction houses like Equip-Bid regularly feature equipment from closing restaurants, including "scratch and dent" units with minor cosmetic flaws. Be aware of buyer's premiums (10-15%) and tight pickup schedules.

Local used equipment dealers provide a middle ground. They buy, refurbish, and resell commercial equipment, often with a short warranty. You might pay slightly more than a private sale, but you get inspected equipment and peace of mind. Our guide on Used But Not Abused: Finding Quality Pizza Prep Tables on a Budget offers more tips.

Don't forget shipping costs. A used sandwich station is heavy, and freight shipping can add $300-$800 to your cost. Large units require a loading dock or liftgate service, and you're responsible for moving it into your kitchen. This is why local pickup is often the best option. It eliminates shipping costs and allows for a pre-purchase inspection. If you opt for pickup, plan for a rental truck and bring help, as these units are heavy.

Success in buying a used sandwich station requires patience and preparation. Know your requirements, set a realistic budget including all potential costs, and be ready to walk away if a deal doesn't feel right.

The Pre-Purchase Inspection: Your Essential Checklist

Found a promising used sandwich station? Don't skip the inspection. This step is non-negotiable and can save you from a costly mistake, no matter what the seller claims. A thorough inspection is your best protection, as most used equipment sales are "as-is."

Assessing the Condition

Use your eyes and hands to check every detail. Minor cosmetic issues are expected, but look for red flags.

- Rust and Dents: Check the entire unit, especially seams and the bottom, for rust or deep gouges. Minor dents are fine, but significant damage could indicate underlying problems.

- Door Seals and Gaskets: Run your fingers along the rubber seals. They should be soft and pliable, not hard, cracked, or torn. Bad seals mean the compressor works overtime.

- Hinges and Drawers: Open and close all doors and drawers. They should move smoothly without sticking or wobbling. Misaligned parts are a sign of wear.

- Missing Parts: Look for shelves, pan divider bars, and other components. While you can find replacements, as shown in our guide on Don't Lose Your Cool: Where to Find Pizza Prep Table Parts, missing pieces add to your total cost.

Verifying Functionality

Now, see if the used sandwich station actually works as it should.

- Plug It In: Listen to the compressor. It should hum steadily, not rattle or bang.

- Check Temperature Holding: Let the unit run for 30-60 minutes. Use your own thermometer to verify that the pan rail and base hold a food-safe temperature between 33°F and 41°F. Don't just trust the display.

- Inspect Condenser Coils: If accessible, check the coils (usually at the back or bottom). They should be clean, not caked in dust and grime, which forces the compressor to work harder.

- Ask for Maintenance History: Service records are a great sign that the previous owner took care of the equipment. Proper maintenance is key to reliability and meeting Food Safety Guidelines for Restaurants.

A careful inspection takes time but can save you hundreds in future repairs. Be picky now to avoid headaches later.

Keep It Cool: Maintaining Your Second-Hand Prep Table

Congratulations on your smart purchase! Now that you've got your used sandwich station up and running, let's talk about keeping it happy and healthy for years to come. Think of maintenance as an investment in your investment – a little care now saves you big headaches (and repair bills) later.

The good news? Commercial equipment is built tough, and with proper care, your second-hand prep table can outlast many newer, cheaper models. Here's how to keep your workhorse running smoothly.

Daily cleaning is your best friend. Wipe down all surfaces with food-safe cleaner – the cutting board, pan rail, exterior stainless steel, everything. Remove and wash those food pans thoroughly. This isn't just about looks; it's about preventing bacteria buildup and keeping your prep table functioning efficiently.

Weekly deep cleans make a huge difference. Empty that refrigerated base completely, wipe down the interior, and give those shelves some attention. Once a month, take the extra step of removing the cutting board and cleaning underneath it. You'd be surprised what can accumulate there!

Condenser coil cleaning is where many people drop the ball – and it's probably the most important maintenance task you'll do. These coils are like your unit's lungs. When they're clogged with dust and kitchen grease, your compressor works overtime, driving up your electric bill and shortening the unit's life.

Check those coils every month or two (more often in dusty or greasy kitchens). Unplug the unit, locate the coils (usually behind a grille at the back or bottom), and give them a good brushing and vacuuming. If they're really grimy, a specialized coil cleaner works wonders.

Those door gaskets deserve some love too. Remember how carefully you inspected them before buying? Keep that attention going. A weekly visual check and monthly cleaning with warm, soapy water will keep them flexible and effective. Here's a pro tip: close a piece of paper in the door – if it slides out easily, your gasket might need attention.

Temperature monitoring should become second nature. Your used sandwich station needs to maintain consistent temperatures between 33°F and 41°F. If it starts struggling despite clean coils and good gaskets, you might need a certified technician to check refrigerant levels. An annual professional check-up is smart insurance for any used equipment.

Don't forget about the drain pan or condensation lines. These areas can develop mold or odors if neglected, but a quick monthly cleaning keeps everything fresh.

For detailed troubleshooting tips, check out our guide on Fixing Your Pizza Prep Table Without Losing Your Toppings. And always follow FDA food safety practices – proper maintenance isn't just about equipment longevity, it's about keeping your customers safe and your business running smoothly.

A well-maintained used sandwich station often outlasts a neglected new one. Your future self (and your wallet) will thank you for the extra care you put in today. For more insights on food safety standards, our Food Safety Guidelines for Restaurants page has you covered.

Frequently Asked Questions about Used Sandwich Prep Tables

After helping countless restaurant owners steer commercial kitchen equipment, I've noticed the same questions come up again and again about used sandwich stations. Let me share the answers that matter most to your business decision.

What's the average lifespan of a commercial sandwich prep table?

Here's some great news that might surprise you: a well-maintained commercial sandwich prep table from a quality brand like True or Continental can easily serve your kitchen for 10-15 years or more. I've personally seen units that have been running strong for two decades with proper care.

This longevity is what makes a used sandwich station such a smart investment. When you find a 3-5 year old unit from one of these top manufacturers, you're essentially getting a piece of equipment that's just hitting its stride. It's already proven its reliability in a real kitchen environment, yet still has many productive years ahead.

The key factor here is maintenance. A unit that's been properly cleaned and serviced will far outlast one that's been neglected, regardless of its age. This is why asking about maintenance history during your purchase is so important.

Can I get a warranty on a used sandwich prep table?

The warranty situation with used sandwich stations varies quite a bit depending on where you buy. Let me break down what you can realistically expect.

Most private sellers and auction purchases come with the standard "as-is" arrangement - meaning once you buy it, it's completely yours, including any problems that might surface later. This is the most common scenario, which is why that pre-purchase inspection we talked about earlier is absolutely critical.

However, some refurbished equipment dealers do offer limited warranties, typically ranging from 30 to 90 days. These dealers have usually gone through the unit, replaced worn parts, and tested everything thoroughly. While you'll pay a bit more than a private sale, that peace of mind can be worth it, especially for newer business owners.

Always ask about warranty coverage upfront - even if it's just a 30-day guarantee, it shows the seller stands behind their equipment.

Is it better to buy a used sandwich prep table or a new, budget-brand one?

This is probably the most important question I get, and my answer might surprise some people. In most cases, I'd strongly recommend a used sandwich station from a top-tier brand over a shiny new unit from an unknown manufacturer.

Here's why this strategy makes sense for your business. Superior build quality from established brands like True, Continental, or Hoshizaki means these units are engineered to handle the demanding environment of a commercial kitchen. They use thicker stainless steel, better insulation, and more robust compressors.

The reliability factor is huge too. A quality used unit has already proven itself in a working kitchen. You know it can handle the daily grind because it's been doing exactly that. Budget brands are often untested in real-world conditions and might fail just when you need them most.

Parts availability is another critical consideration. When your prep table needs service (and eventually, all equipment does), finding parts for major brands is straightforward. Budget brand parts can be impossible to source, turning a simple repair into a complete replacement.

Even from an energy efficiency standpoint, a well-maintained premium brand unit often outperforms a cheaply made new one. Better insulation and quality components mean your compressor doesn't have to work as hard, saving you money on electricity bills month after month.

A used sandwich station from a respected manufacturer represents a much better long-term investment for your kitchen's success, even if the initial sticker price seems higher than that tempting new budget option.

Conclusion

You've made it through the complete guide to buying a used sandwich station, and now you're armed with everything you need to make a smart purchase. This isn't just about pinching pennies – it's about making a business decision that can transform your kitchen's efficiency while keeping more money in your pocket.

Think about it: saving 50-70% off retail prices means you can invest that extra cash into better ingredients, marketing, or even expanding your menu. That faster ROI we talked about? It's real, and it can make the difference between struggling through your first year and thriving from day one.

The beauty of buying a quality used sandwich station from brands like True or Continental is that you're getting proven reliability at a fraction of the cost. These units have already shown they can handle the daily grind of a busy commercial kitchen. With proper maintenance – that regular cleaning schedule and condenser coil care we covered – your used prep table could easily serve you for another decade.

Remember those key takeaways: inspect thoroughly before buying, prioritize top brands over budget new units, and always factor in shipping costs when shopping online. Whether you find your perfect unit on eBay, at a restaurant auction, or through a local dealer, stick to your checklist and trust your instincts.

At PizzaPrepTable.com, we've seen countless restaurant owners transform their operations with the right equipment choices. Your used sandwich station isn't just a piece of equipment – it's the foundation of efficient food prep that keeps your customers happy and your costs manageable.

Ready to start your search? Explore our full range of sandwich and pizza prep table refrigerators to find all your options and find the perfect fit for your kitchen's needs!